Authentise announced a new feature for their MES system called “Guidelines”.

The company builds a cloud-based manufacturing execution system they call “aMES”, which is able to coordinate activities necessary to perform additive manufacturing at scale. There’s many more steps and participants involved beyond the printing, and an MES is becoming a requirement these days.

Functions typically found in an MES are quoting, order handling, product inventory/selection, work dispatch, tracking, billing and more. With a cloud-based system there’s also the advantage of using the MES across a distributed set of locations and participants.

There are several MES systems on the market, but most of them offer what could be termed a “prescriptive” approach. In other words, the MES makes assumptions about what steps are involved and when they should take place.

Most of the time they are correct, or in the case of new entrants, these essentially define what the company should do, having no existing process.

But what about companies that already have extensive processes? What if they differ from the MES’ assumptions?

In some cases that would definitely disqualify the use of the MES entirely. Why blow up everything just to get into additive manufacturing?

What’s needed is a more flexible approach by MES software that is better able to integrate with existing — and new systems, as well as change directions depending on the circumstances. How does Guidelines do this? Authentise explains:

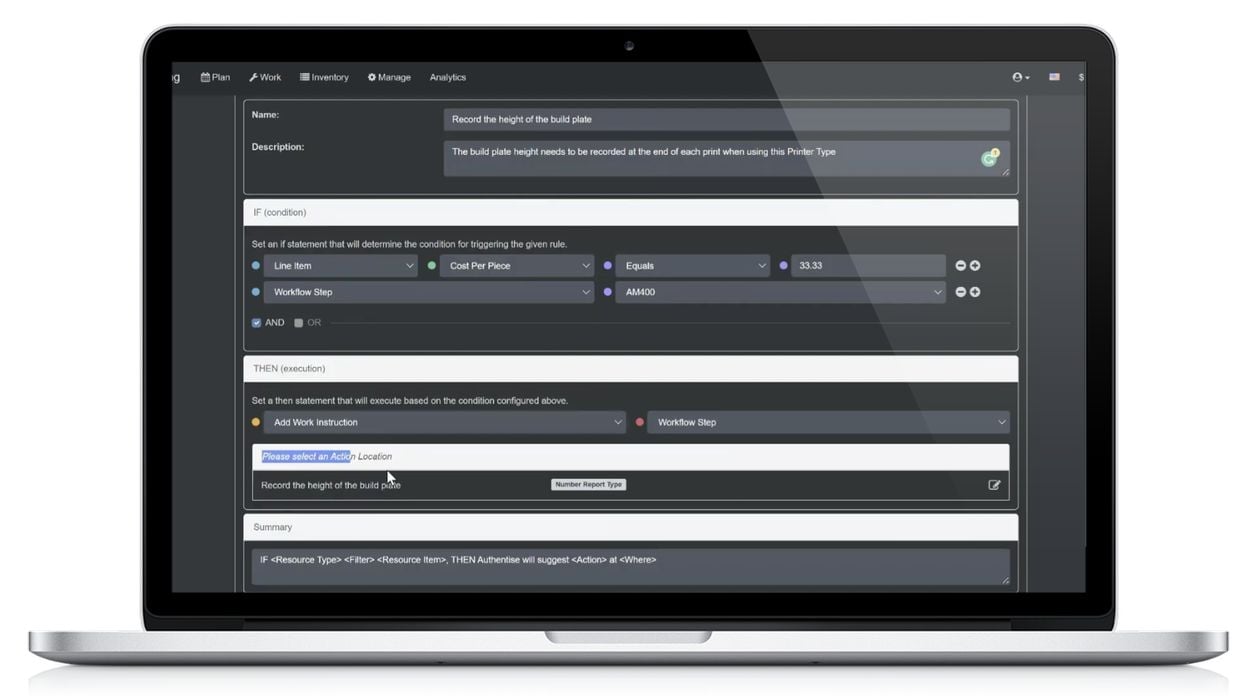

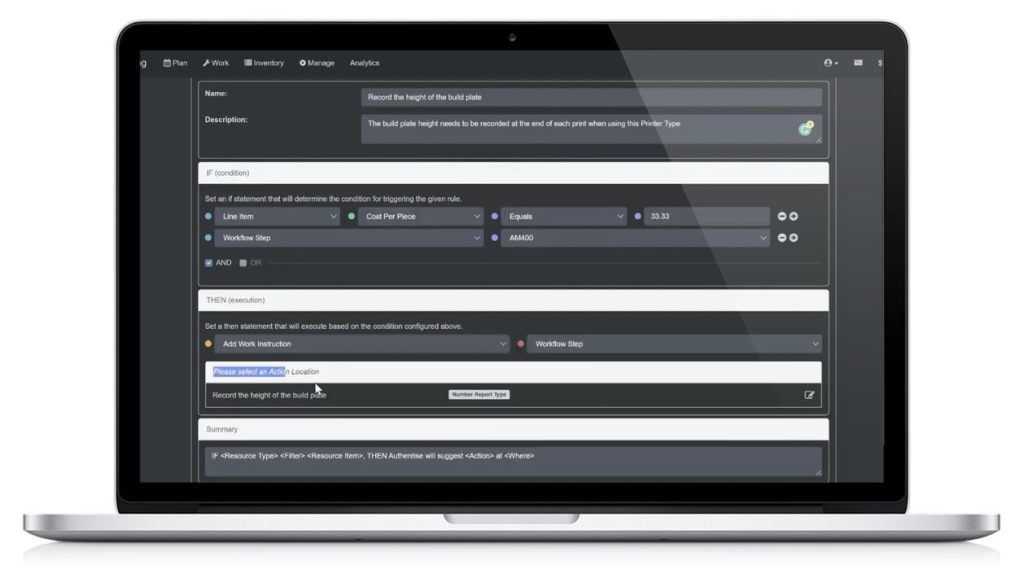

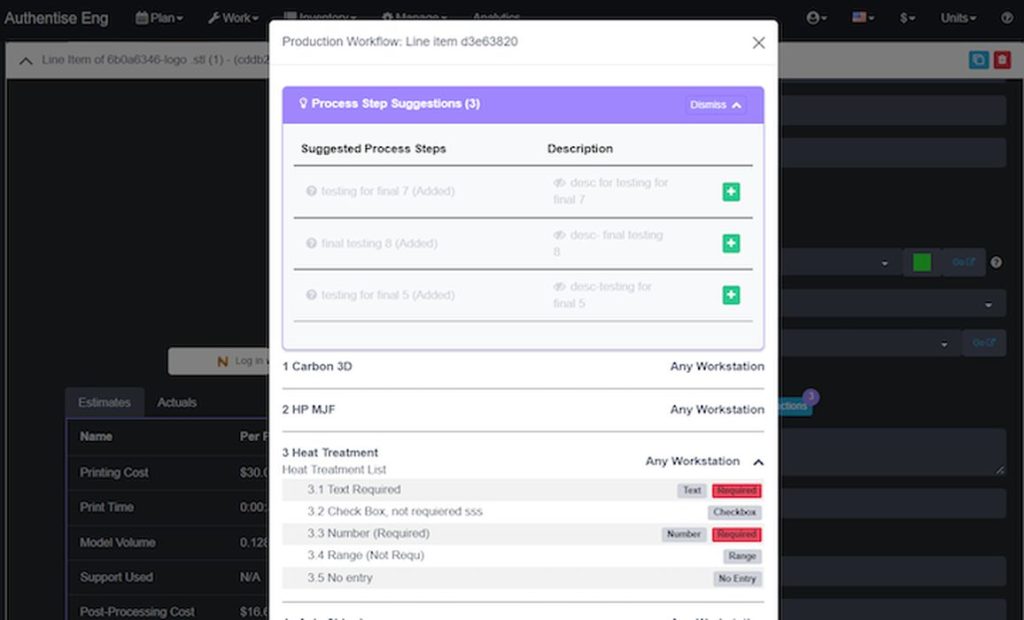

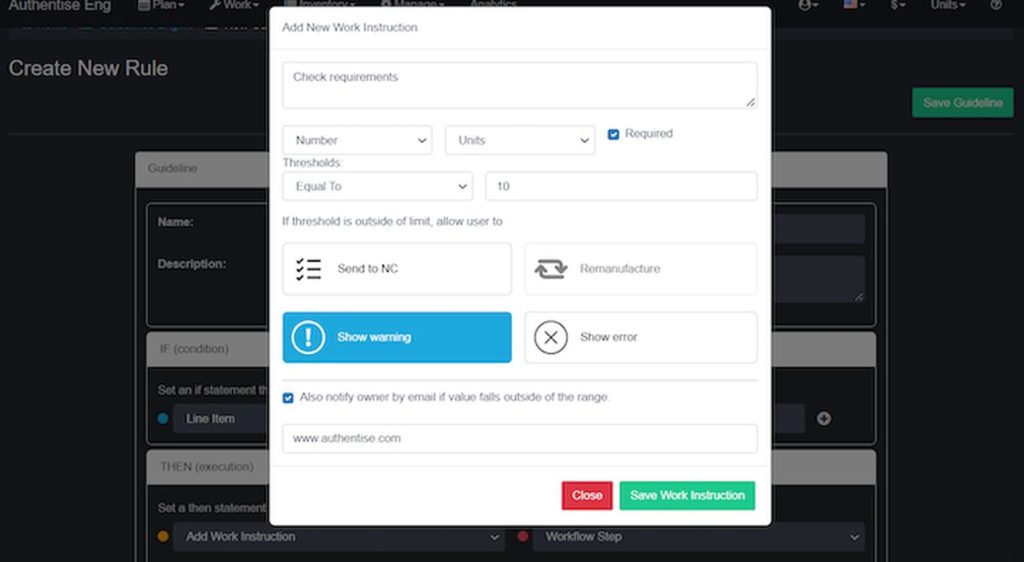

“Guidelines is a new set of features accessible to users of aMES, Authentise’s end-to-end, connected workflow engine for additive manufacturing. It enables users to formulate if-this-then-that rules that use any type of engineering or production data as input. These rules then trigger suggestions at any point in the process. With Guidelines, a combination of machine sensor feedback, geometry features, or QA measurements, among others, can be used as triggers to suggest changes in behaviour or parameters that will ensure a more successful and sustainable production outcome. These suggestions are delivered to the user when required, during the engineering stages or in production.”

Basically, Guidelines allows the MES operator to add a series of executable “rules”, which can potentially alter the sequence of events based on numerical data. By composing an appropriate sequence of these rules, the operator could implement a new and complex manufacturing workflow.

Authentise CEO Andre Wegner said:

“We realized their broader power almost immediately and spent the last 10 years building, with aMES, a contextual data engine capable of harnessing them. They represent a break from more prescriptive tools, such as our workflow generator. This permissive approach makes them the ideal channel to ensure that rules are followed while giving experienced engineers and operators the latitude to make the decisions necessary on a case-by-case basis. We’re fortunate to work with partners such as ASTM to ensure that this novel framework is not only filled with tribal knowledge present within each organization but uses existing standards as a starting point.”

This could be a very important feature for manufacturers, as Guidelines provides significant flexibility in process design.

Guidelines should allow manufacturers to differentiate their execution process from competitors, potentially lowering costs with ingenious optimization steps, speeding up processing by re-organizing work sequences based on data. These changes, all in the hands of the MES operator, could provide a notable advantage over their competition.

Authentise describes Guidelines as a “major new rules engine” and that it “puts operators back at the heart of digital manufacturing”.

I think they could be correct.

Via Authentise