Authentise acquired Elements Technology, a company providing easy access to manufacturing management services.

Authentise provides services necessary for manufacturers using additive technologies. While we all dwell too long on machine specifications, the truth is that the 3D printer is just one piece in a long workflow required to get things done for clients. Buying a machine doesn’t get you those other functions, and you’re on your own.

Authentise is one of several companies offerings services to knit machines and process together. Their aMES “data driven workflow management” solution is a manufacturing execution system able to collect information from equipment and participants to provide a complete view of operations.

That’s part of the puzzle, but there’s more things that a manufacturer would need to do, and that leads to their announcement today of the acquisition of UK-based Elements.

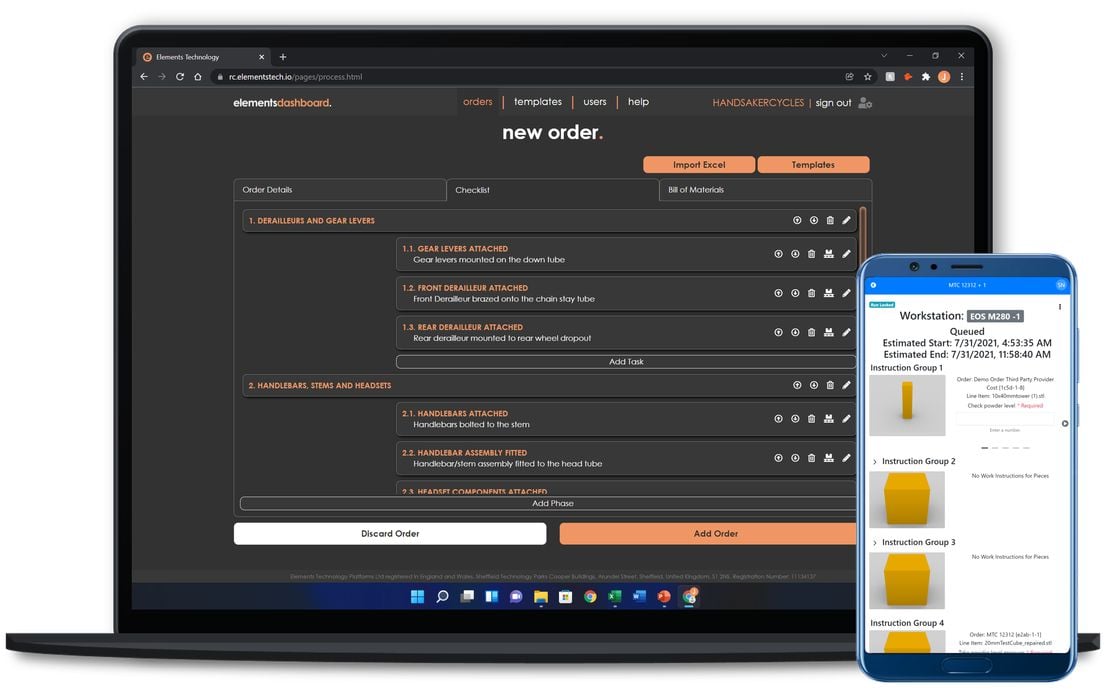

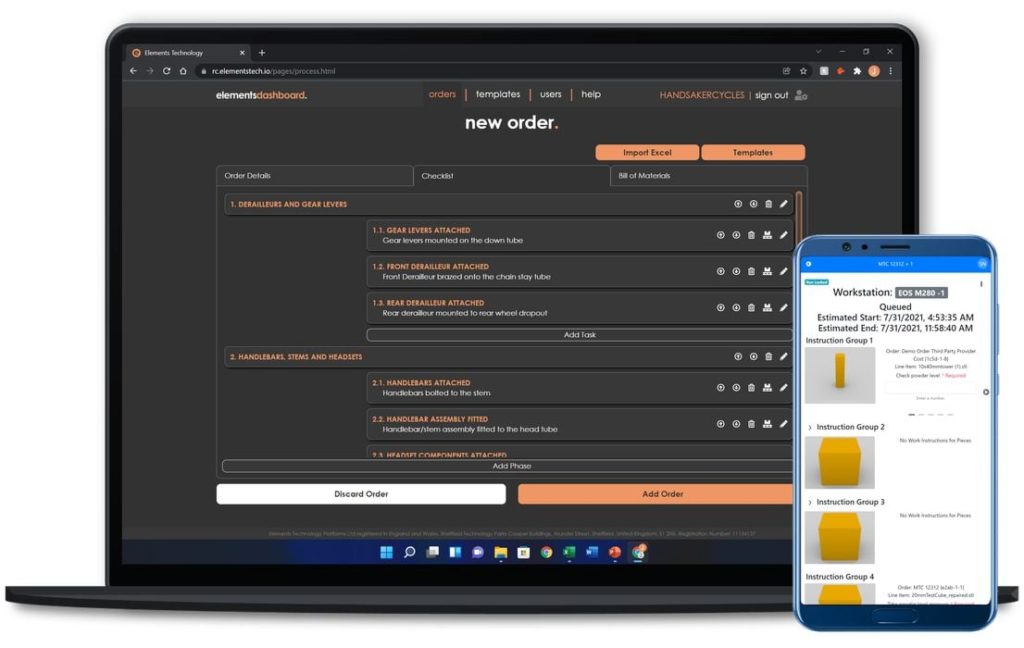

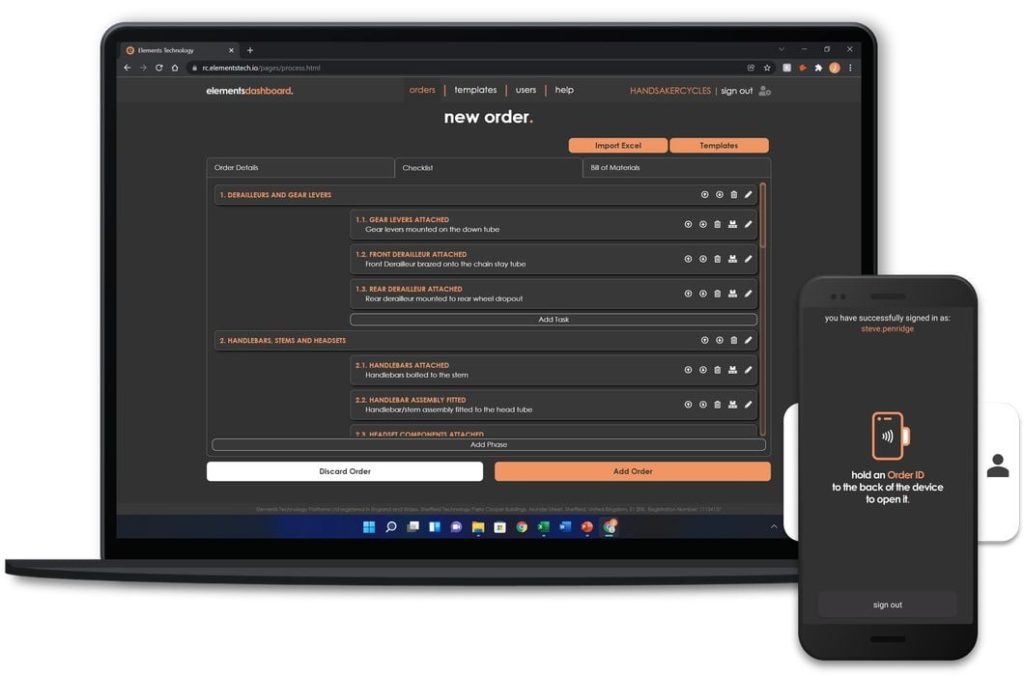

Elements Technology offers a service for order and production management for general manufacturers. Using their “Docket” system anyone in the company can see what’s going on and what needs to be done next.

They’re trying to address the Industry 4.0 movement, where all activities become digitized. Normally this is done by big companies with big software budgets, and plenty of consulting. Elements Technology’s philosophy is to get moving in that direction without the cost. This is an ideal service for small to medium-sized manufacturers.

Authentise said:

“The partnership enables discrete manufacturers everywhere to access connected workflow management solutions used by the world’s leading additive manufacturing companies to manage their lot-size 1 operations efficiently, flexibly, and transparently.”

The acquisition provides a window for new services by Authentise, particularly in non-AM companies where they don’t currently operate. This could be a way for Authentise to grow significantly, as there are more non-AM manufacturers than not.

Authentise CEO Andre Wegner explained:

“Elements is the perfect addition to the Authentise portfolio. Like Authentise, Elements have been laser focused providing manufacturing operations with the flexibility they need in the post-pandemic world with the efficiency that data enables in the 21st Century.

Elements provides customers with a unique self-serve tool for all types of manufacturing operations, to quickly create, capture and access repeatable shop floor processes. Delivering intelligent production planning & scheduling, and real time views of production customers can track orders, like they’re paying for coffee. These exciting services will become a key part of the combined Authentise portfolio.”

Elements Technology CEO Joe Handsaker said:

“The real story of Industry 4.0 has yet to be written. The last 20 years have been wasted focusing on predictive maintenance and analytics, which have yielded very little Return on Investment. It’s time to refocus on what’s core to manufacturing: the worker. Supporting them with data and modern tools gives us more context in manufacturing and allows us to drive better quality, insight, and completely new business models. If nothing else, the pandemic has shown that a radical rethink of the way things are made and delivered is necessary. We’re delighted to have found a partner that understands that and are excited to build a better future, together.”

Authentise has been slowly piecing together an increasingly complex service, ultimately intending on providing all the services required by manufacturers. So far we’ve seen them:

- Integrate Solukon

- Partner with Riven

- Partner with Hexagon

- Partner with nebumind for digital twin features

- Add material management

- Integrate Addiguru in-process monitoring

- Partner with Microsoft

- Developed a mobile app

- Partner with Autodesk

And there’s many more similar announcements from the company over the past few years.

Via Authentise and Elements Technology