Aurora Labs provided an update on their ongoing metallurgy project with Gränges.

We haven’t heard too much in the last while from Australia-based Aurora Labs. The company has been developing a massive metal 3D printing system that, when complete, will be able to 3D print one tonne of metal material per day. The idea is to use this capability to enable 3D printing for applications where it is not presently feasible using existing metal 3D printing systems.

Gränges is a Swedish company you may not have heard of, but you will be hearing from a lot more as they’re making a bold move into the 3D printing space.

They are a large-scale provider of aluminum products for industry, particularly for heat exchangers. They have a long history of growth through acquisition, and it seems that is the case with this latest episode.

In late 2020, Gränges acquired the shares of GETEK, and with those new resources they created a new line of business called Gränges Powder Metallurgy.

In other words, we have a major metal provider suddenly entering the metal powder business. Readers will know what that means: they’re also entering the 3D printing market, which has been growing steadily in the metal segment due to aerospace and automotive applications.

It turns out Aurora Labs and Gränges have been working together to certify use of specific metal powders from this venture. They explain the project’s goals:

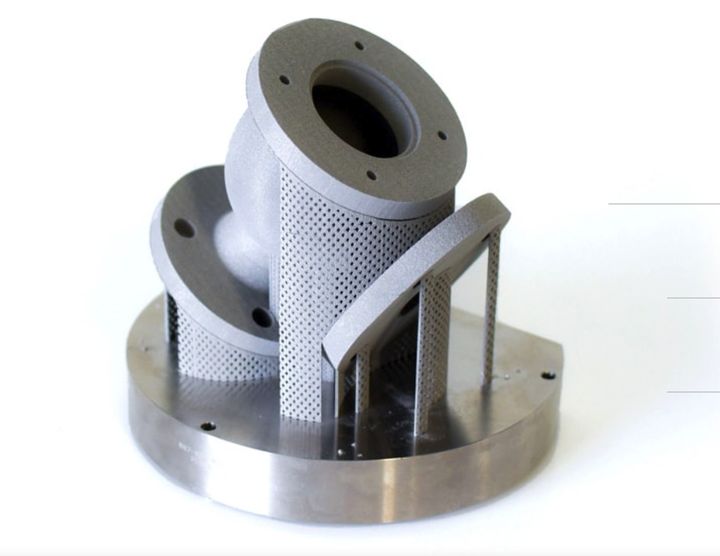

“The intention of the project was to explore the material properties of sample parts printed with specialist aluminum alloy powders and establish the likelihood of those powders having successful applications in powder bed fusion additive manufacturing.”

No doubt the experiments were performed on Aurora Labs’ metal 3D printer.

While the project continues, they do explain their approach:

“During the project, A3D (Aurora Labs) has studied metallurgical coupons printed with two Gränges aluminum alloy powders and developed comprehensive material characterizations of the samples produced. The samples were subjected to internal A3D testing, delivering favorable results. Following this, Gränges conducted a full range of material property testing, the outcomes of which are encouraging for further development work. The parties will be investigating printing specific parts utilising the tested alloys for existing Gränges customers.”

It would appear that Aurora Labs is on the verge of a multi-faceted deal here. First, they’re lining up a supplier of quality metal powder for their equipment, and certifying at least two alloys, with likely others to follow. Then, they’re also set to gain a potentially large amount of customers through Gränges’ client list.

It’s extremely interesting to learn that one of Gränges’ specialties is production of material for heat exchangers. This is a notable application for 3D printing, as heat exchangers can be made to work more efficiently by using new geometries that can only be 3D printed.

It may be that Gränges is about to launch Aurora Labs forward several steps.

Via HotCopper (PDF) and Aurora Labs