Funding has been provided to researchers working on an “atomic” 3D printer for producing solar cells.

This is research that I feel will start in one direction but end in another.

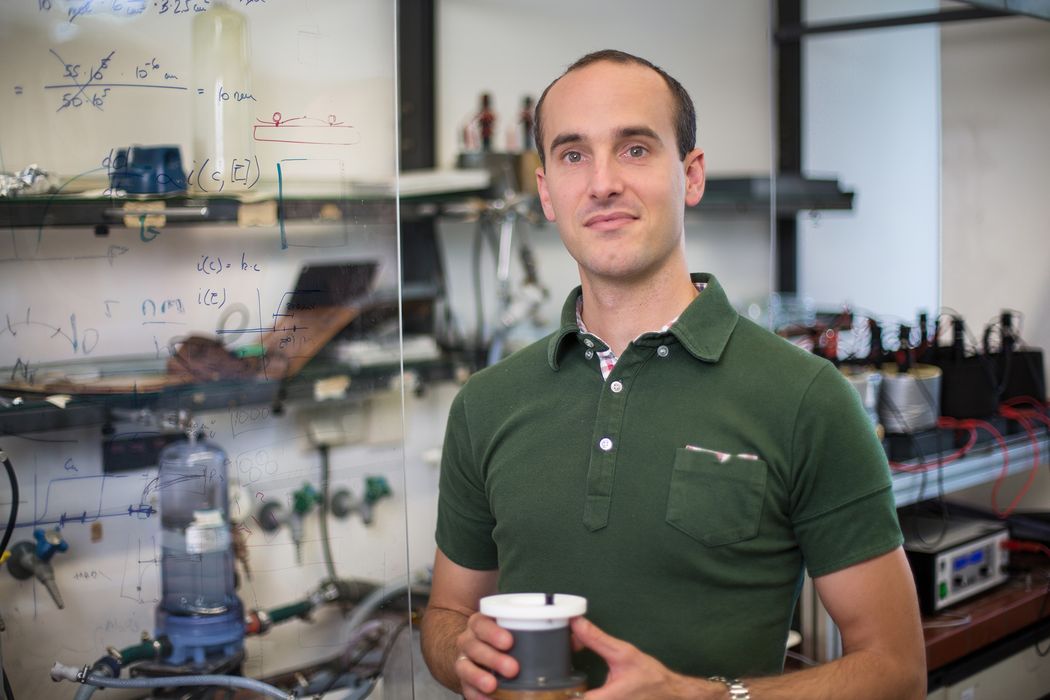

The research is being undertaken by Prof. Dr. Julien Bachmann at Friedrich Alexander Universität in Nuremberg, and is triggered by the need for advanced solar cells.

While virtually all of today’s solar cells are produced using silicon and conventional manufacturing processes, attempts to build them using alternative materials and lower-cost manufacturing processes have yielded cells with poor efficiencies. This is why the standard solar cell making techniques persist.

Bachmann’s prior research has determined that the reason for the inefficiencies is due to the microscopic surface structure. He and team believe that it is possible to 3D print the necessary surface structure using a sufficiently precise process, and achieve both cost savings and cell efficiency goals.

How precise does this 3D printer have to be to meet the requirements? It turns out Bachmann hopes to use a new process capable of an incredible resolution of only 0.000001 mm. To put that number in perspective, it is 100,000X smaller than the typical layer size on a desktop 3D printer.

The process producing these results is called “ALAM”, for “Atomic Level Additive Manufacturing”. FAU explains:

“Unlike conventional silicon-based methods where shapes and structures are manufactured by removing superfluous material, the new method involves depositing the semiconductor directly into the required shape from the outset. This method saves material. In order to print precisely with an accuracy of 0.000001 millimetres, the individual atoms are transported and attached to the surface using molecules designed specifically for this purpose.”

This process will be used in an attempt to produce highly efficient and inexpensive solar cells.

But after reading about ALAM, it seems to me that this technology could be used in a far more general sense, rather than just being used for the production of solar cells. For example, if you can 3D print solar cells, then it’s likely you can also print extremely small electronic circuits. That is a capability that has long been desired in the 3D print world, and incorporation of it into standard 3D printers might enable one-job printing of functional devices.

The ability to deposit individual atoms is quite powerful: there are many types of atoms and they can be combined into different materials. If Bachmann’s ALAM process is able to use different types of atoms efficiently at scale, I can’t imagine the potential for this approach.

Via FAU (Hat tip to Benjamin)