Artec 3D released the latest version of their scanning software, Artec Studio 17.

The Luxembourg-based company has been producing professional 3D scanning solutions for over a decade, and the key to their success has been their powerful software.

3D scanning is often seen as a hardware issue, but in reality is it actually a software challenge. Once the raw point cloud is collected using the hardware, it’s up to the software to make something useful and provide functions that complement the intended uses for the scan. That’s the core value of Artec Studio.

We had a chance to evaluate Artec Studio in detail last summer as part of our previous hands on test of the company’s portable Leo 3D scanner. At the time we found the software to be amazingly powerful in its ability to create and manipulate 3D models.

Now the company has increased the functionality of Artec Studio with the new version 17 release.

Along with the usual speed-ups in processing and user interface improvements, Artec 3D has included some rather interesting new functionality into the software tool.

A brand new feature provides a way to map a high resolution 2D color texture image to 3D geometry. Evidently this would be best used by those creating perfectly textured models for CGI use. The application of the higher resolution images to the object surface would result in a better quality overall texture than simply relying on the texture captured during a scan.

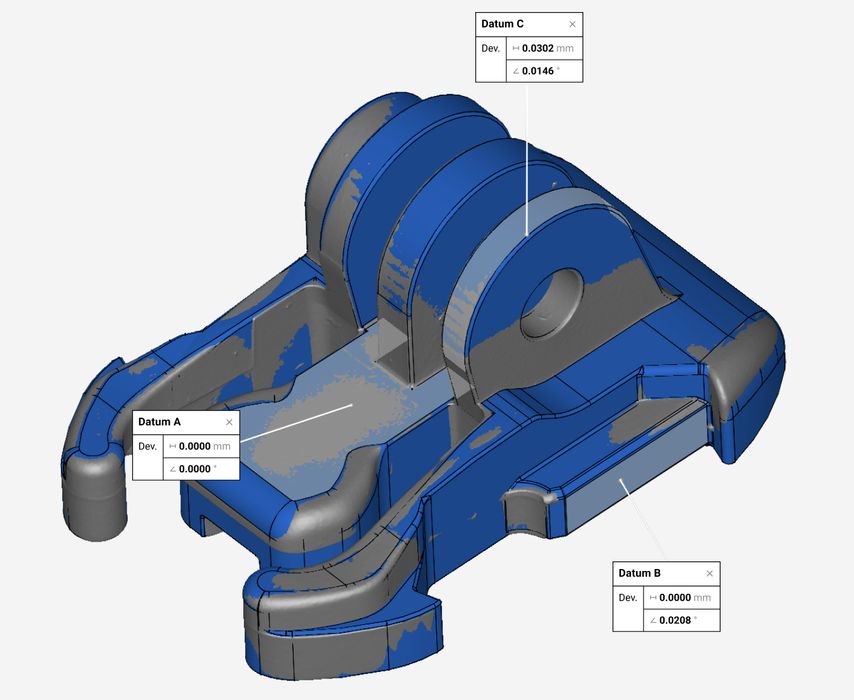

Artec 3D has improved the inspection capabilities in the new software release. Inspection is the process of comparing the scan of a manufactured (or 3D printed) part to verify that it follows the intended design from the CAD file, at least within tolerance levels.

The new inspection process is streamlined, and allows alignment of CAD and scan by only a few clicks to match geometric features. There are an increased number of options to process these comparisons, including the ability to focus on particular reference objects, exclude zones or perform explicit measurements.

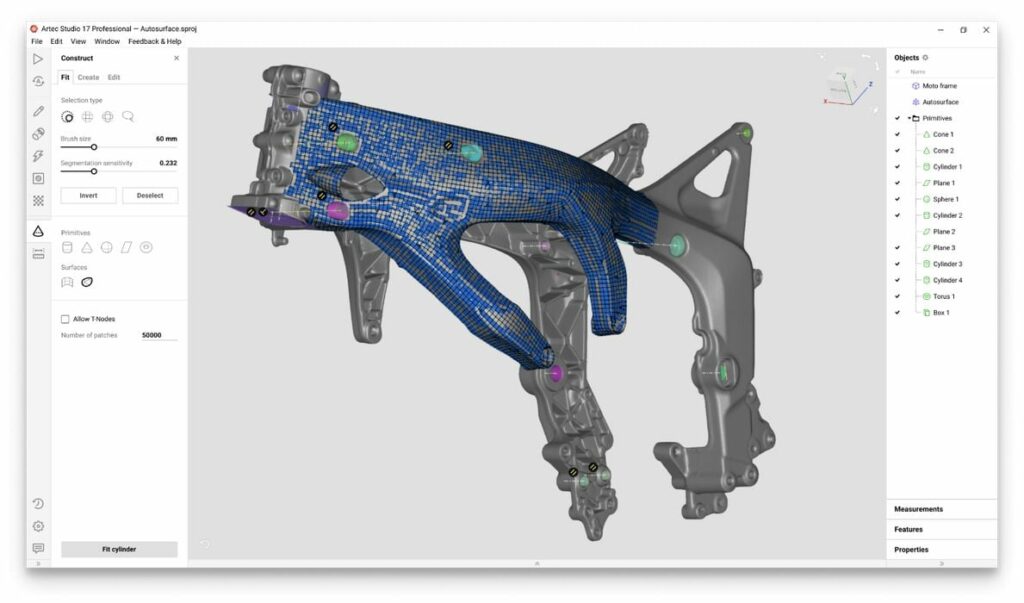

But the most interesting new feature in my opinion is the enhanced reverse engineering features. These allow you to generate a CAD model from a 3D scan, which is typically used when an older part is required but there’s no CAD model. Companies implementing digital inventory systems will certainly encounter this scenario frequently.

Artec Studio 17 apparently allows “complete reverse engineering” within a single tool. They say:

“Artec Studio 17’s new features allow engineers to scan an object and completely reverse engineer it all in one software, streamlining design and manufacturing workflows. The innovative Auto Surface tool enables one-click conversion of complex organic shapes into solid CAD models, while with the addition of Boolean operations, users can modify models with CAD entities and meshes using the Union, Subtract, and Intersect tools to create products such as customized molds and packaging.”

This is quite notable, as we should see an increased need for reverse engineering as companies go deeper on digital inventory. Some companies will have thousands of parts that require scanning and reverse engineering, so anything that can optimize that process could be incredibly valuable.

The new Artec Studio 17 is immediately available to all current subscribers.

Via Artec 3D