With the announcement of a new set of biologically safe filament materials, it’s time to talk about what that means.

The materials in question were announced by PPPrint, a German firm specializing in the production of polypropylene materials. “PP” is an increasingly popular 3D print material as it provides a number of interesting properties, not the least of which is that it is extremely durable.

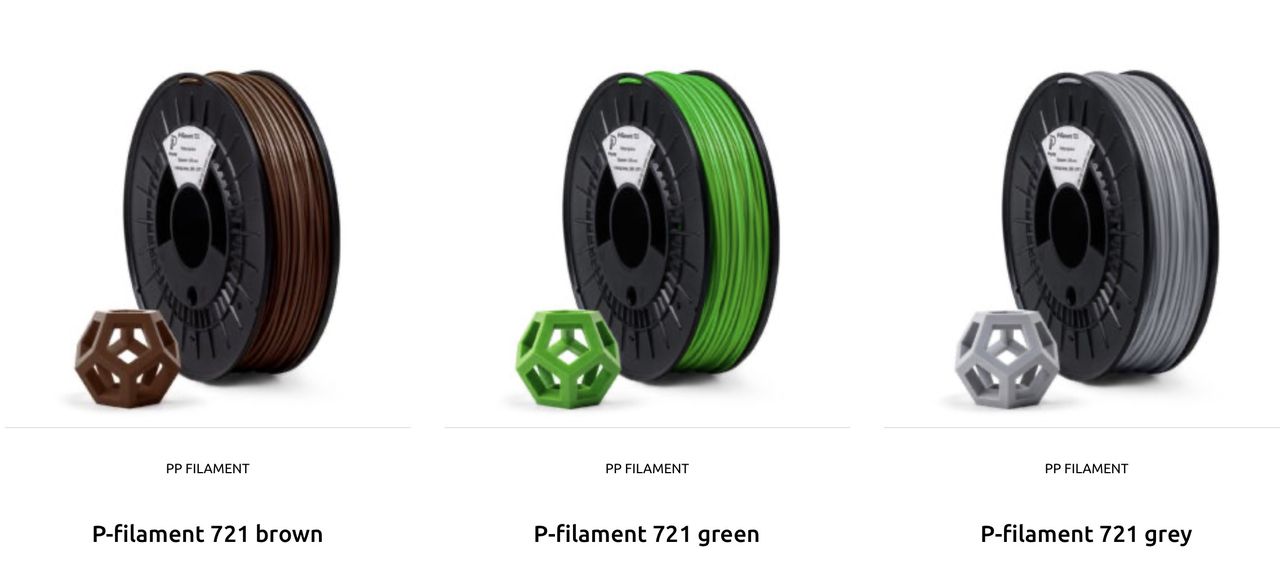

The materials are all the color variants of PPPrint’s P-Filament 721 series. These have been certified against DIN EN ISO 10993-5. What’s that standard about? ISO explains:

“ISO 10993-5:2009 describes test methods to assess the in vitro cytotoxicity of medical devices.

These methods specify the incubation of cultured cells in contact with a device and/or extracts of a device either directly or through diffusion.

These methods are designed to determine the biological response of mammalian cells in vitro using appropriate biological parameters.”

In other words, it’s been certified to be harmless if exposed to human tissue. You can place it on skin, for example, without fear of toxicity.

PPPrint wrote:

“Our ‘P-filament 721’ is thus not only suitable for medical technology applications, such as the production of orthoses and prostheses, due to its excellent chemical and mechanical properties, but also enables these products to be used in direct skin contact with patients.

We are also very pleased that our ‘P-filament carbon 411’ has also been certified as biologically safe and therefore suitable for skin contact applications.”

That’s all fine, but does this mean that anyone can 3D print objects using this material and assume they are free of toxins?

Absolutely not! There is a chain of events that leads to a printed object, which is the accumulation of all the steps involved. The material itself is only one part of the equation to build an object.

The main issue is the 3D printer that uses the filament. As the filament is used during a print job, it passes through several portions of the 3D printer, touching various components.

The filament could possibly slide inside PTFE tubes, potentially scraping up some PTFE, for example. The filament will grind up against the extruder gears as well, and finally pass through the hot end and nozzle.

The nozzle is perhaps the most interesting step in this scenario, as it presents considerable heat. In a hot state it’s possible the material could absorb more material than when solid. The material will touch the metal of the nozzle, potentially causing contamination.

The contamination would involve the metals used to make the nozzle. Could there be lead in the nozzle? Possibly. Do you even know what your nozzle is made from?

Biologically safe filament can be used to print biologically safe objects, but only if used on a biologically safe 3D printer. These rare machines would have upgraded components all along the filament path to ensure they are made from materials that do not allow toxic levels of contamination.

Just because a filament is biologically safe doesn’t meant mean you can make biosafe objects with it.

Via PPPrint