AON3D announced a new IDEX feature for their high temperature 3D printers.

The Montreal-based company has been producing very well regarded industrial 3D printers for several years. The niche they specialize in is high temperature materials, which are highly sought after by engineers.

The demand for high temperature materials is caused by the thermal resistance. It means that the parts can exist in environments with raised temperatures, whereas typical thermoplastic parts would soften and fail.

In many environments the temperature range is low enough to permit the substitution of a high temperature polymer part for the original metal part. This means the application could result in a lower weight because polymers weigh less than metals.

That’s all caused a run on high temperature 3D printers that can produce not only lightweight complex geometry parts, but also lightweight polymer parts that can be swapped in for heavier metal equivalents. Typically these are end-use parts, not prototypes, requiring quality control and repeated production.

AON3D is one of the few companies making production-ready high temperature 3D printing equipment.

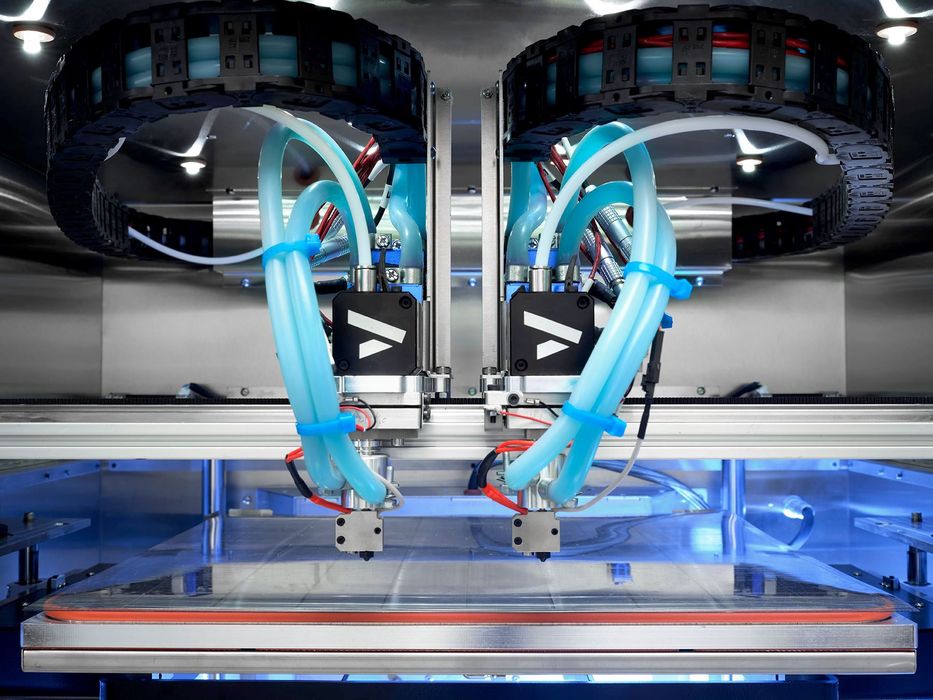

Now they have broken through an important barrier: IDEX, or InDependent EXtrusion. This is a technique where the build chamber holds not one, but two separately operated extrusion systems. They operate on the same X and Z axis as each other, but move along the Y axis independently.

The benefit of IDEX is that two prints can take place at the same time in the build chamber. If the parts are sufficiently small to fit both, then this can literally double the throughput of the machine.

AON3D said:

”AON M2+ High Temperature Industrial 3D Printer will be receiving an optional firmware upgrade to enable Duplication Mode and Mirror Mode 3D printing. This powerful new feature will double the output of new and existing M2+ machines to meet the growing demands of factory floors.”

Duplication mode means two copies of the same object are produced. Mirror mode means the second copy is “mirrored” and printed. An example of a mirrored print might be two sides of a mold.

Note that this is a firmware upgrade, not a hardware upgrade. The AON M2+ always had the dual extrusion system installed, but it was typically used to have two types of materials available during a print job.

The new firmware “turns on” the ability to use that hardware for the production of two objects simultaneously. AON3D said the firmware upgrade will be included on all new AON M2+ devices, and can be installed on existing devices in the field. The upgrade is expected to be available in the fall of 2022.

I am not aware of other high temperature 3D printing gear that permits duplication or mirror modes. This suggests that the AON M2+ could be a vastly more productive acquisition than some other high temperature 3D printers: if they can produce twice as many parts in a day, then it’s worth double the value.

For an AON M2+ operator, this effectively means that the cost of the equipment could be halved, as it is like buying two printers in one.

That certainly enables more production capacity, but also the ability to defray the machine cost over twice as many parts produced. This would lower the cost to their customers — or raise the profit margin, depending on the circumstances.

This is a very good move by AON3D.

Via AON3D