AON3D has done something no 3D printer has done before: print solid Kapton parts.

The Montreal-based company has been quite successful marketing their powerful high temperature 3D printer. More recently they have been exploring the use of a more varied set of high temperature materials.

While the system is officially an “open materials” device, the company has been certifying several powerful engineering materials. They say:

“AON3D lets you print using the strongest plastics and composites available in the world. Here are some options below. If there’s something you want to use, but don’t see it contact us and we’ll help you unlock it.”

Their official material catalog now includes:

- VICTREX AM 200 (LMPAEK)

- PEEK

- Carbon fiber reinforced PEEK

- PC

- PVDF

- ASA

- PPSU

- PETx

- PC-ASA

- POM (a.k.a. Delrin)

- ULTEM 9085

- TPE

- PVC

- PPS

- ABS

- PPA

- PC-ABS

- PA

- TPU

- HIPS

- PSU

- PP

- PC-PBT

- PMMA (a.k.a. acrylic)

AON3D also has certified use of Aquasys 120, a rare high-temperature soluble support material.

Now there’s another very intriguing material to add to their list, Kapton.

Kapton, also known as poly-oxydiphenylene-pyromellitimide, is well-known in industry as it has a very unusual characteristic: it is thermally stable between -269C to +400C. This makes it ideal as a polymer insulator for electric circuits.

In fact, that’s most likely where you’ve seen Kapton used: it’s that yellow-orange film often seen surrounding an electrical connector.

Another place you may have encountered Kapton is as a 3D print adhesion surface. Kapton has been used as a film overtop build plates to help PLA and ABS properly adhere. However, that practice has largely been replaced by the more common PEI-coated magnetically attached removable plate systems of today.

Now Kapton returns to the world of 3D printing, but this time as a material. AON3D has used a custom filament of the high-temperature material made by Zymergen and run it through their machine.

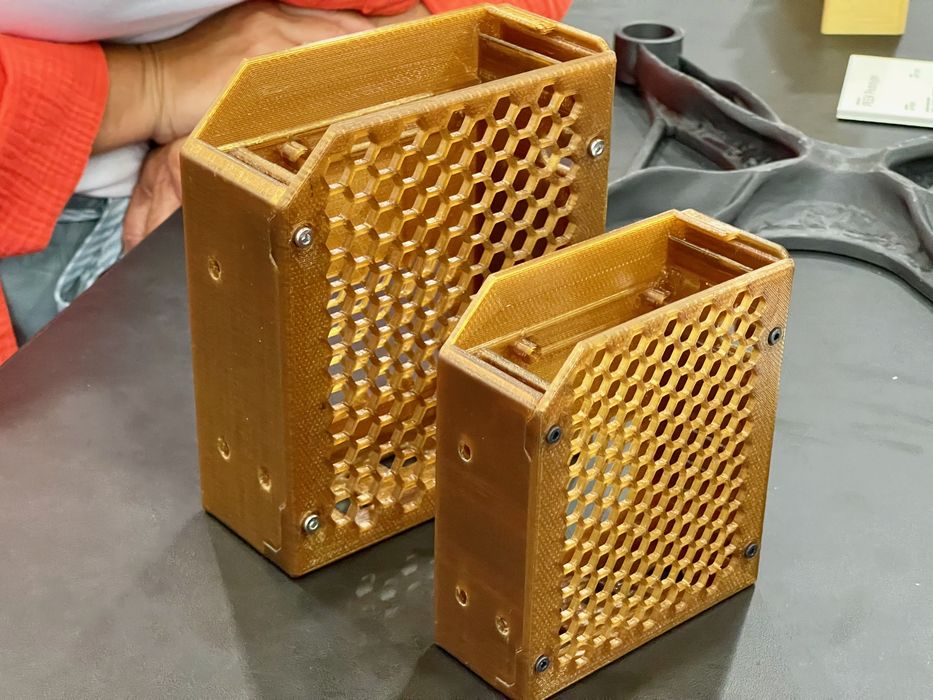

The result is the print shown at top, with the characteristic yellow-orange color, except now it’s in solid form.

It’s unclear how Kapton prints could be used, as apparently the material has lousy resistance to mechanical wear, and it degrades in the presence of humidity.

Nevertheless, it’s possible there are new applications that might open up due to the possibility of 3D printable Kapton. While there are certainly high-temperature applications for Kapton, I’m particularly interested in the lower temperature range of Kapton’s capabilities, which must be among the lowest in polymers.

My thought is that AON3D has performed the Kapton experiment as a demonstration of the broad capabilities of their M2+ 3D printer, which is very often used by institutions as a materials research platform. If it can 3D print solid Kapton, what else could the M2+ do?

That usage pattern has been so successful that an AON3D representative told us they have had their “best (financial) quarters ever!”

Via AON3D