Recently I’ve seen several projects using 3D printing to produce highly advanced antennae, and this is likely to be a significant application in the future.

Antennae are a technology we use every day, whether we realize it or not. Your smartwatch has an antenna, and so does your mobile phone. Your workplace has WiFi antennae, and your neighborhood will have LTE (or 5G if you’re lucky) antennae.

Antennae used to be simple: a metal conductor of appropriate length to pick up the desired wavelengths. However, problems of strength and directionality quickly arose, and thus began pursuit of radical antenna designs to overcome these and other issues. Today it’s a very challenging area, particularly due to increasing mobile requirements.

Radio waves are actually just photons in wavelengths your eyes can’t detect, and so the advanced antennae of today act much like telescope arrays to catch as many photons as possible. Their geometry can be quite complex.

3D Printed Antennae

Fabbaloo readers will know what that means: antennae are an excellent candidate for 3D printing technology, which can handle highly complex geometries.

And indeed, there is now considerable activity in the 3D print space on the antenna problem. We’ve seen examples of conformal antennae, and 5G MIMO antenna designs.

Now there’s another unique antenna design that is fascinating.

Rhosoon Intelligent Technology is an antenna manufacturer and they’ve been working with Farsoon to produce a radically new type of antenna for a mobile 5G solution.

Luneberg Lens

Specifically, they’re using a design called a “Luneberg Lens”. I’m pretty sure you haven’t heard of this design; I certainly had not.

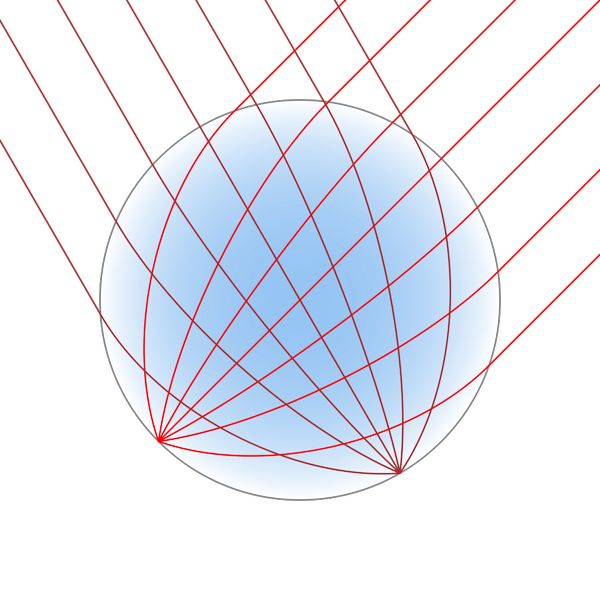

The Luneberg Lens outwardly appears to be a sphere, but the secret is inside. According to Wikipedia:

“A Luneburg lens is a spherically symmetric gradient-index lens. A typical Luneburg lens’s refractive index n decreases radially from the center to the outer surface. They can be made for use with electromagnetic radiation from visible light to radio waves.”

In other words, the interior of the Luneberg Lens sphere has a refractive gradient: its refractive index increases as you move towards the center of the sphere. The curve of the gradient depends on what wavelengths you’re trying to catch, and can be determined precisely by Luneberg’s equations.

You can imagine how complicated it would be to try to build something like a Luneberg Lens using conventional approaches. Using 3D printing as a solution here is clearly the correct approach.

That’s precisely what Rhosoon Intelligent Technology did with their Farsoon’s 403P system, a production SLS 3D printer. They were able to 3D print lens modules with the gradient dielectric constant and form usable Luneberg Lens spheres. For material, they used Farsoon’s FS3300PA, a PA1212 material.

These were installed on a test mobile vehicle in an array seen here:

Rhosoon Intelligent Technology found this solution to be “significantly smaller” and also lightweight, adding to the benefits in a mobile environment. Farsoon says they have achieved “100% series production” using this technique.

I believe this is yet another extraordinary example of how the field of antenna design could be revolutionized by the incorporation of 3D printing technology. Future antennae should be more powerful, but also lightweight and in far more designs than you see today.

Via Farsoon