Anisoprint continues to grow through a series of challenges.

We had a chat with Anisoprint founder and CEO Fedor Antonov recently about the company’s latest moves and the industry in general.

Anisoprint is a Luxembourg-based manufacturer of one of the rarest items in 3D printing: a continuous carbon fiber 3D printer. Their technology can lay down lengths of carbon fiber, unlike the chopped carbon fiber found in many common filaments these days. This makes for the strongest possible 3D printed parts.

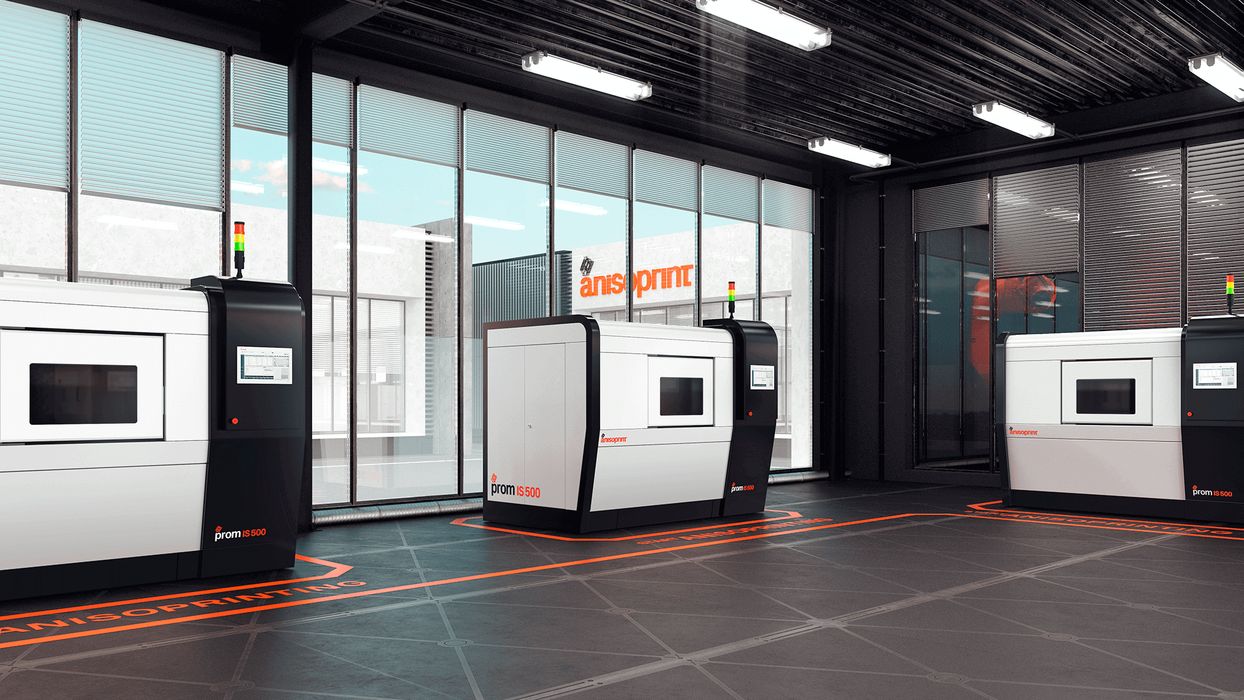

Anisoprint’s Industrial-Sized 3D Printer Near Full Production

Anisoprint has been developing an industrial-sized version of their technology, which was first launched in desktop form some years ago. These machines are designed to run 24/7 in production environments.

Antonov told us the new industrial machine is no longer a prototype, but is now a beta machine. It seems as if they are nearing full production for this device.

Challenges During the Pandemic Impact Anisoprint’s Progress

The company announced this machine quite some time ago, but faced a series of challenges during the pandemic. For example, they found the lead time for CNC controller boards was an incredible 50 weeks, driven by chip shortages.

But building a machine is only one step: once built, the machines must be sold.

Building Sales and Distribution Networks to Drive Growth

To that end, Anisoprint has been working to solidify their sales and distribution networks. For example, they have set up a new office in Shanghai, where the new APAC General Manager will transfer from Anisoprint’s previous local partner, and devote 100% of their time towards Anisoprint. This provides the company with significant expertise and familiarity with the region.

Understanding the Technology and Optimizing for Continuous Carbon Fiber

Even then there are still challenges: Antonov said that the continuous carbon fiber technology is different from typical 3D printers, and takes some learning to “get it”. He said:

“Resellers have to understand the technology, let alone the clients!”

Another challenge facing the company is design: parts to be printed on this equipment obviously need to be DfAM (designed for additive manufacturing), but also for continuous carbon fiber optimization, and that’s quite new to many.

I know that many large companies have “design books” that assist new engineers to create parts in the expected form, but these will have to adapt to include the optimization for continuous carbon fiber.

Anisoprint Set to Ship First Machines to Aerospace Company

Nevertheless, Anisoprint is set to ship the first machines shortly. An unnamed aerospace company purchased two units, and there are other sales lined up.

Those challenges can definitely be overcome, and that’s what Anisoprint is working through. I’m confident that they will be successful.

Via Anisoprint