Believe it or not, there is an open source electron beam metal 3D printer project underway.

The project, launched by Agustin Cruz, hopes to produce a relatively inexpensive design for a style of 3D printer that until now has only been accessible from manufacturers supplying the industrial market.

Cruz, based in Chile, has been working on this project for many years. He explains the motivation for the project:

“The goal is to make 3D Metal Printing more affordable for makers, hospitals, small institutions, organizations and companies around the world. Specifically for developing and low income countries. This project fills a gap that no open hardware successfully fills.”

Apparently Cruz is working full time on this highly ambitious project, which doesn’t surprise me.

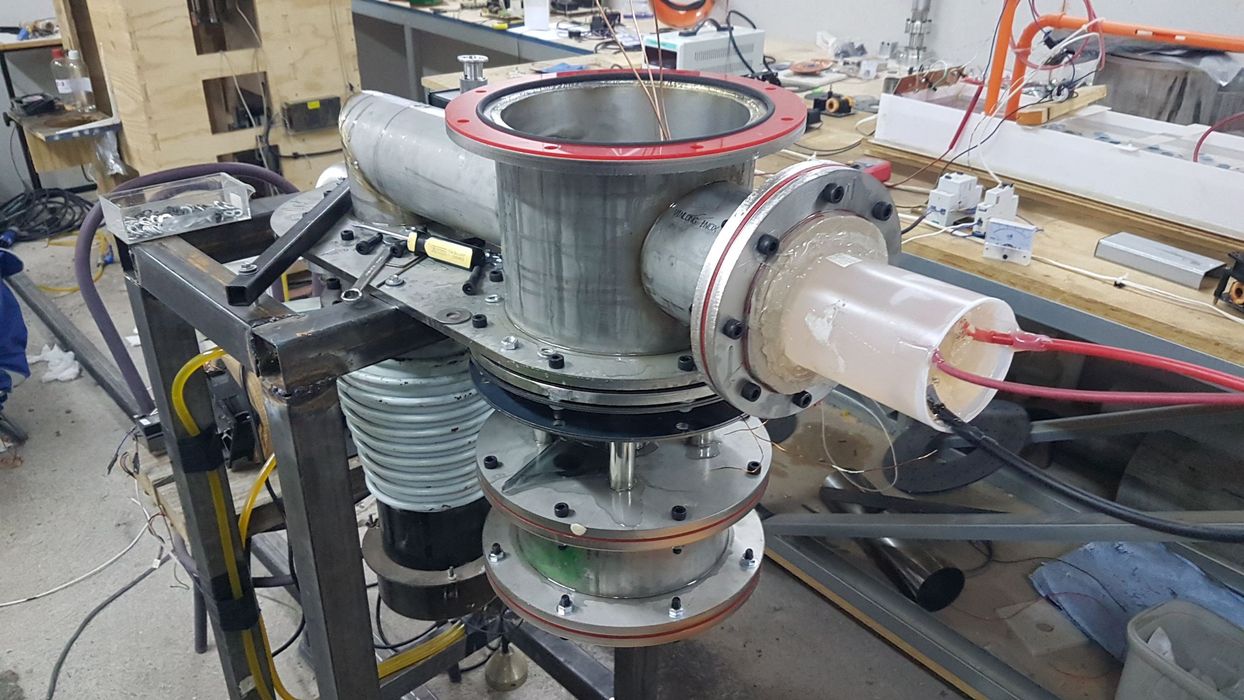

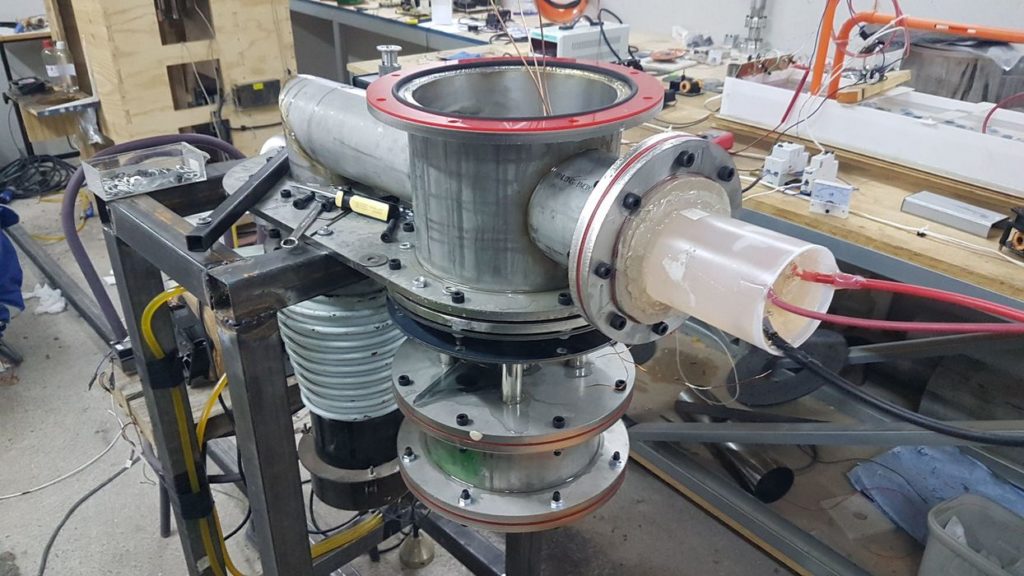

The process being used is electron beam melting, a variation of the PBF process. Basically there is a flat bed of metal powder, which is traversed by a powerful electron beam. The beam selectively fuses portions of the layer into solid metal. After a recoating of more powder, another layer proceeds and fuses into the prior layer. At the end of the process you have a metal object buried in metal powder, ready for post processing.

This project is ambitious because of the complexity of metal 3D printing. Let’s consider some of the challenges facing this project.

Safety: Metal powders can be toxic or even explosive. This makes any metal PBF process quite hazardous, and is why it is necessary to evacuate the build chamber of oxygen. Normally this is done by filling the chamber with nitrogen or argon gas.

Safety Again: The powerful electron gun emits strong radiation, up to 20,000V, and this must be contained to the build chamber and focused on the powder bed.

Quality: The presence of humidity and oxygen can easily corrupt a metal 3D print, as chemical reactions occur that result in flawed structure. It is essential to completely control the environment — atmosphere, temperature and humidity — in order to obtain proper prints.

Warping: Metal prints are notorious for warping due to the extreme temperatures used to fuse the particles. This usually requires heavy build plates, complex software and real time controls to manage environmental temperatures. Software must carefully engineer support structures not only for physical support, but also to convey heat properly to minimize part distortions.

Powder Handling: Powder is easily polluted with oxygen and moisture and must be held secure during all steps. You can’t just “pour” powder into the machine, for example. Similarly, powder can be reused after a print job, but it must be securely removed and sifted to filter out stray blobs.

As you can see, this is definitely not like building a standard FFF 3D printer. There are many more considerations, and that’s why commercial metal 3D printers are so expensive.

Cruz said the system will consume 1500W, with about 100W for the electron gun. The remaining power is used to run the rest of the system, including vacuum pumps to maintain proper build chamber atmosphere.

The project has to deal with all of these concerns in addition to the “printing part”. That’s quite a challenge.

Could this work? It appears that Cruz has quite a way to go, but he is making progress. Here we see a sintering test with iron oxide:

Should this project succeed, it could become a base hardware set for a series of open source derived electron beam 3D printers, similar to how several open source FFF 3D printer designs triggered most of today’s larger 3D printer manufacturers.

However, it will be considerable time before this project can release a fully complete system. One big challenge Cruz will have is that due to the complexity of the system, it will be more difficult to attract contributors that normally take up much of the work in open source projects.

But perhaps in a few years we may see this concept available.