Researchers at the University of Oxford have developed a microscopic printer that is made of DNA molecules.

Past research has seen the development of several micro machines made of small numbers of molecules, such as wheels, motors, and other basic mechanical components.

But what if you were to put some of these components together to form a useful machine? The Oxford team has done just that.

This is almost unbelievable, but the research team’s design involves a print surface made of targetable “DNA pixels” that can be linked with other molecules.

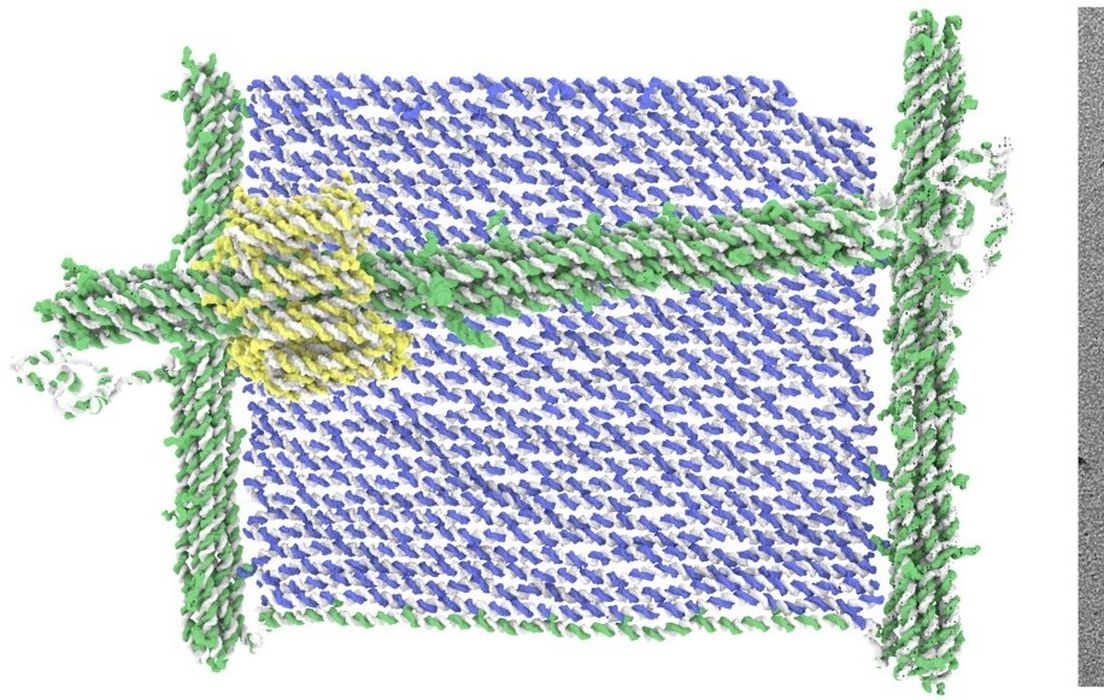

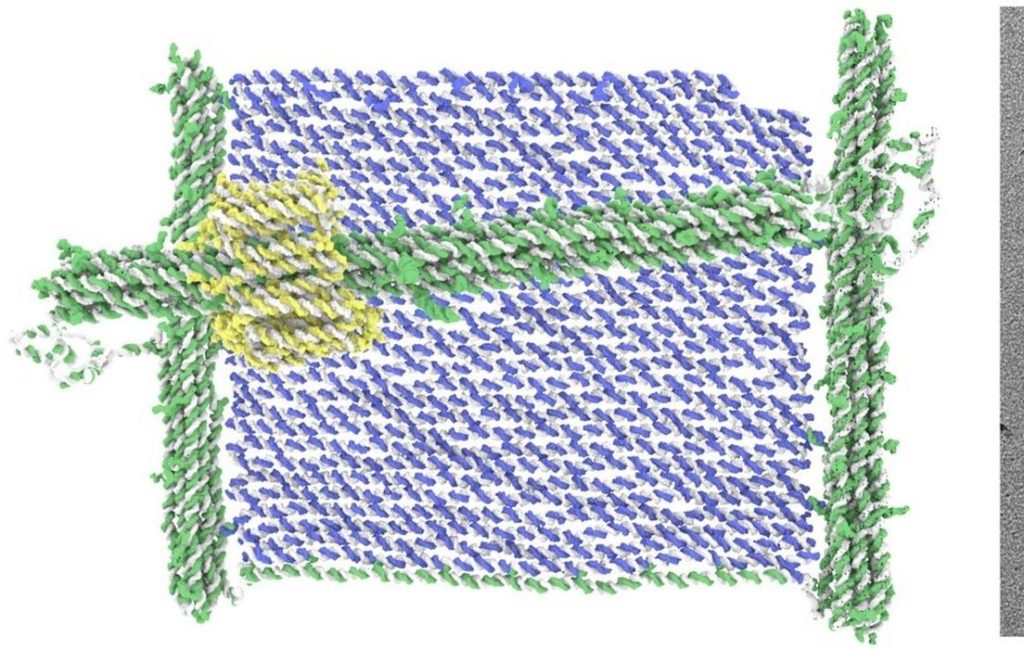

As you can see in the image above, the “print head” is a DNA catalyst sleeve that fits over a beam and can move forward and backward. The device is powered by a couple of DNA linear motors, a previously developed mechanism.

The system is able to be controlled by the introduction of unique DNA “address strands” that “lock the linear motors into position”. The printhead can then deposit “ink” on the appropriate pixel in the flat array.

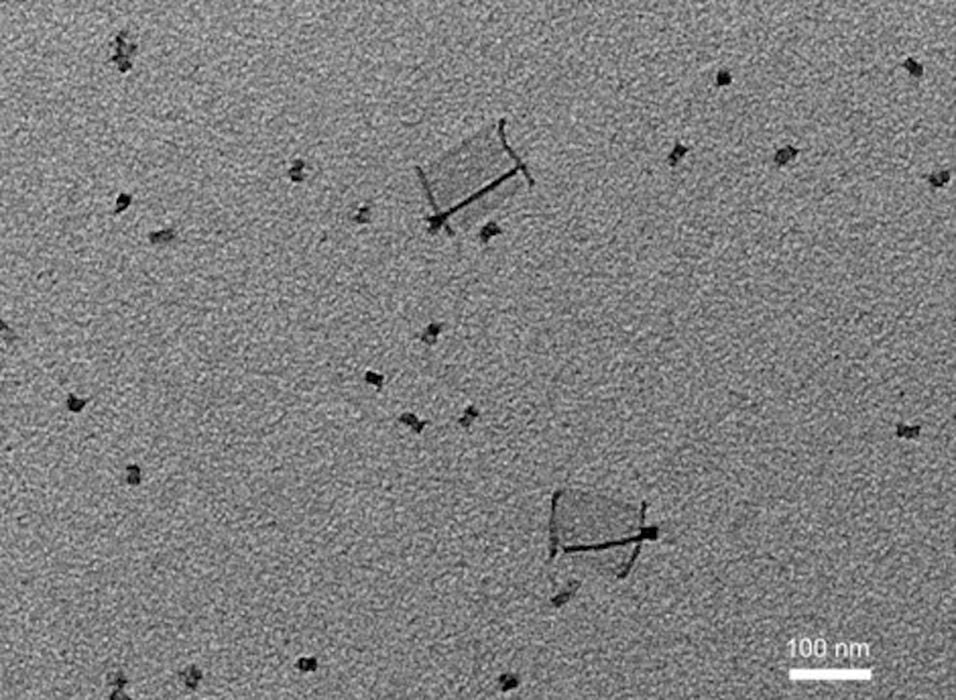

In other words, it can literally print on a surface, just like a 2D printer. The difference here is that this printer and canvas is extraordinarily small. As you can see in this image, the device is only about 100nm (0.0001mm) across.

The researchers believe the device could in future be transformed into a machine that can literally manufacture specific complex chemicals on demand. That alone would be a very significant development in many scientific and industrial fields.

While this is a 2D printer, we are interested in 3D printers at this publication.

Could this technology be adapted for 3D printing? I see no major reason why it could not. The ability to move a printhead along an axis, combined with an ability to deposit material — in this case DNA, should allow the design of a 3D version of this project.

While the concept might have some limitations, most notably that the build volume of this printer is extremely small, it may be that the concepts and mechanisms used in this project could be adapted for a “chamber-less” approach that could construct larger objects.