AMT is secretly working on metal post processing equipment.

The UK-based company has been on a tear in the past couple of years, developing advanced post processing gear for additive manufacturing.

Post processing is the often forgotten aspect of 3D printing that requires specialized equipment and a ton of labor. While you might be able to make the print process faster with improved equipment, more often than not those advances are lost when adding in tedious post processing steps.

For those making one-off prototypes, manually operated post processing equipment is entirely suitable. But when you consider the needs of low volume manufacturing, better post processing solutions are required. Not only must parts be processed swiftly, but they must be processed with identical quality and with minimized labor costs.

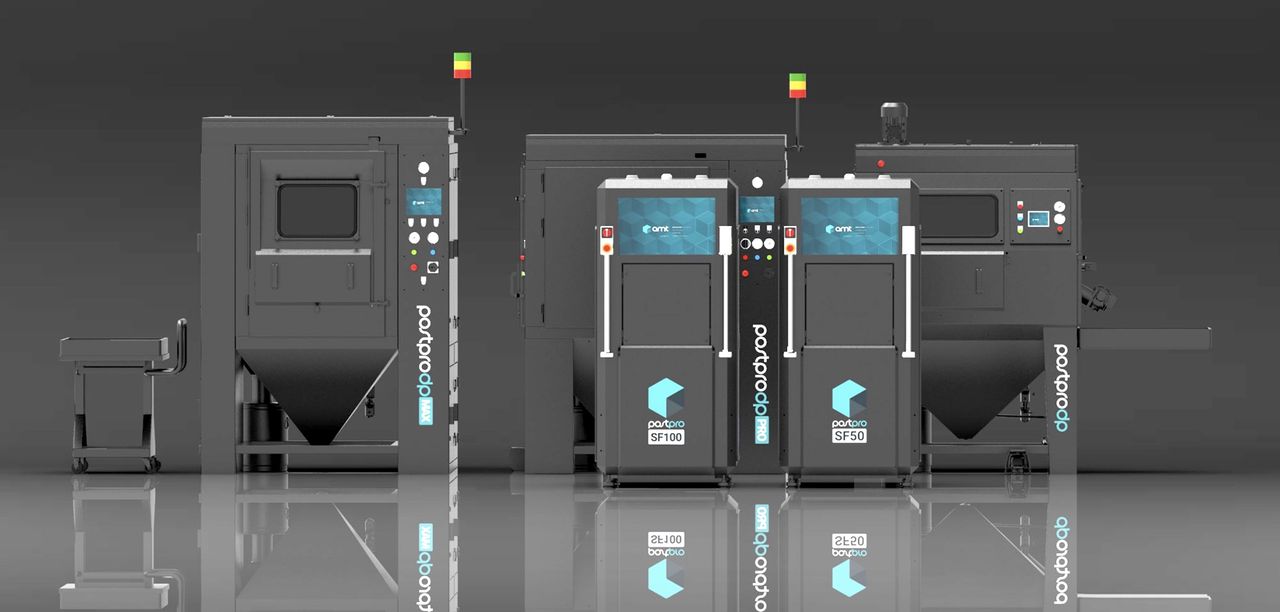

That’s the strategy for AMT, which offers a series of advanced post processing devices to handle polymer 3D prints. Their equipment is “smart” and can deliver consistent results repeatedly through finely tuned post processing profiles.

I had a chat with AMT’s founder, Joseph Crabtree to find out the latest developments at the rapidly growing company.

Crabtree goal is to provide additive manufacturers with a “fully automated, end to end system, enabling 24/7 lights-out operation.”

AMT has had quite a bit of business success. Now in their sixth year of operation, Crabtree said they have been able to double their revenue each and every one of those years.

Initially launched with self-sustaining funding, Crabtree says they are “raising money hard now.” This is no doubt due to their equipment success, and the consequent need to enlarge their marketing and sales activities.

Crabtree did surprise me when I asked what new developments are underway. He said:

“Up to now we’ve been all polymer. But now we’re looking at metals.”

This is quite ironic, as Crabtree himself is a trained metallurgist, while his entire current product lineup addresses polymer post processing needs. To turn to metal post processing is quite a step, but Crabtree has a strategy:

“Metal is a totally different process, but the mechanics of powder are similar to our current processes. Something people may not realize is that we can smooth green parts before they are sintered into solid metal, and we’ve been able to do that with our current equipment.”

This is a very interesting approach that I had not considered. When someone says “metal post processing” I immediately visualize wire cutting, 5-axis CNC milling and sophisticated metal polishers.

But that’s how you handle solid metal prints from PBF equipment. Meanwhile there is a growing acceptance of “cold” metal 3D printing processes, such as HP’s MJF or Desktop Metal’s systems. These produce green parts that require sintering, and before that happens they are more easily smoothed.

It’s a different approach, but as Crabtree told us:

“Who cares which process is used, if you get the finished result?”

He may be right.

Via AMT