Charles R. Goulding and Preeti Sulibhavi examine the value of 3D printing technology for Allbirds, a footwear manufacturer.

Allbirds appears to be taking the sustainable and sensible footwear industry by storm. With consumers, especially millennials, putting increasing importance on comfort and sustainably sourced products, Allbirds has become the choice for many.

It’s been five years since Allbirds’ CEOs, Tim Brown and Joey Zwillinger (both without prior experience) introduced the first Allbirds shoe, the $95 Wool runner. Time magazine labeled it as the “world’s most comfortable shoes.” And, last fall, Allbirds launched its apparel line that derives its materials from discarded shells of marine life, responsibly sourced merino wool, recycled polyester and Tencel, which is harvested from natural materials.

This past summer, it appears that Allbirds had confidentially filed for an Initial Public Offering (IPO), with the company being valued at $2 billion at the time. For 2020, Allbirds reported a net loss of $25.86 million, wider than the $14.53 million loss in the previous year. The company attributed these losses to higher costs related to head count, operations, and digital advertising.

Net revenue rose to $219.3 million from $193.7 million, driven by increases in average order value and the company’s digital sales, which accounts for 89% of its total sales according to Allbirds’ SEC filing.

Despite these losses, Allbirds is going public with hopes that its eco-friendly niche in the footwear market will only boom in the coming years. In fact, Allbirds is taking full advantage of the Environmental, Social and Governance (ESG) investing environment by emphasizing its sustainable status.

We have previously written about how many footwear giants such as Nike, Puma, Crocs, and Adidas have integrated 3D printing into their shoe design and fabrication. Allbirds can take a similar path if it wants to remain on the cusp of cutting-edge technology.

Allbirds and Adidas have in fact collaborated using recycled plastic waste in more than half of the polyester used in its Futurecraft Footprint running shoe products. Going even further Allbirds could potentially collaborate on the Futurecraft Strung project in which Adidas combines 3D printing with robotic automation in the fully recyclable Futurecraft Loop initiative.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

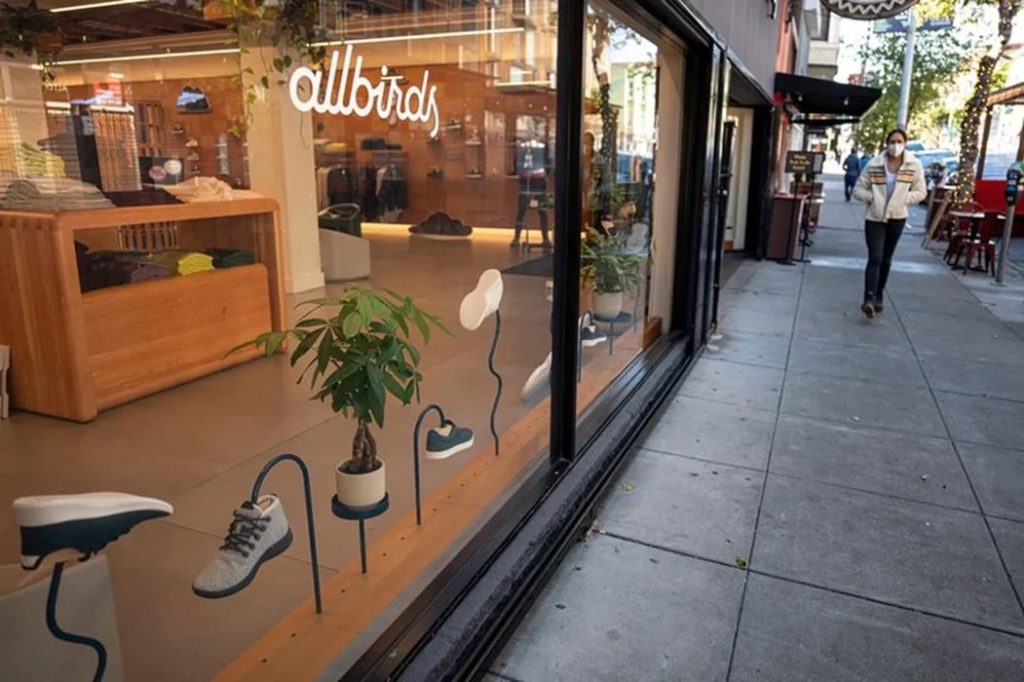

With the funding from its IPO, Allbirds plans on improving its working capital, covering its operating expenses and capital expenditures. And, despite Covid pushing online retail to be its main source of revenue, Allbirds sees its physical stores as an integral part of its operations. It has opened 27 brick-and-mortar retail locations and plans on cutting the ribbons on hundreds more.

It’s not every day that a popular, environmentally friendly, shoe outfit based out of Silicon Valley goes public. And, given the nature of the footwear products, 3D printing can certainly be integrated into Allbirds’ footwear lines. The industry should hit the ground running on this news.