A researcher at MIT has developed a method of 3D printing invisible labels on objects.

The straightforward concept developed by MIT 4th year PhD student Mustafa Doga Dogan could lead to an astonishing future.

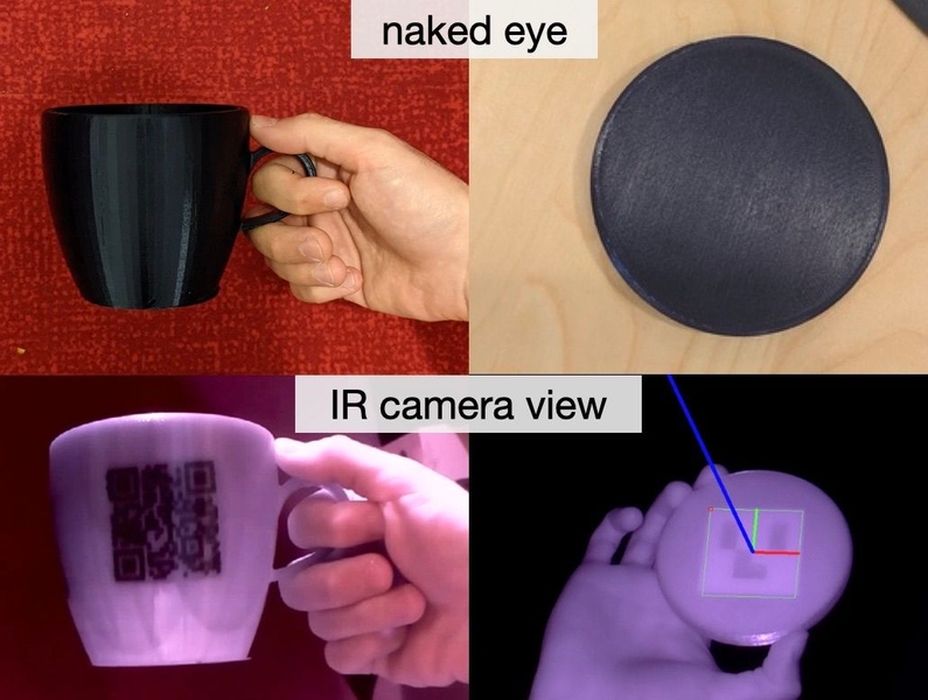

The idea is to 3D print objects, but have embedded codes that are invisible to the eye, but easily seen with infrared light. This capability could use QR codes or similar visual encoding methods to “stamp” information on any 3D printed objects.

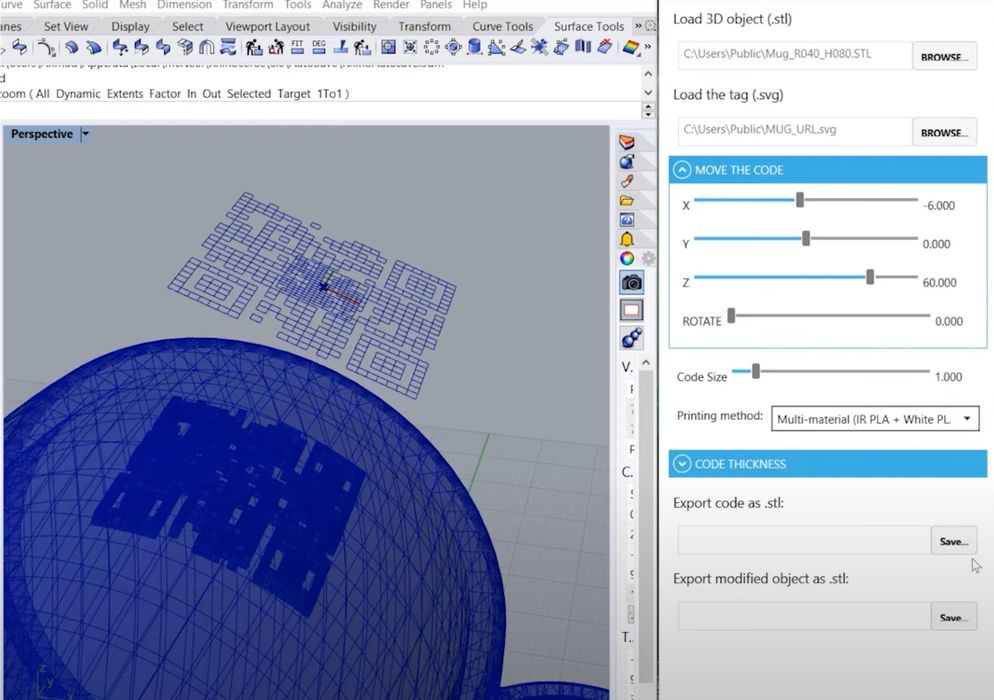

The technique, called “InfraredTabs” is actually quite simple: Dogan sought a 3D printable filament that was translucent to IR light. After some searching he identified an existing product that had those characteristics. Then it was a matter of devising a way to leverage it for labelling.

Two approaches were considered: air gaps and secondary material.

In the first approach a single-toolhead 3D printer could embed small gaps in the otherwise solid structure of the object. These would create a slight contrast as more IR light could pass through the air gaps. However, Dogan found this approach would not provide a great deal of optical contrast, making it challenging for IR cameras and software to reliably detect images.

The other approach is to use a dual-toolhead 3D printer, in which one extruder uses the IR-translucent material for the bulk of the object, and the other extruder holds an IR-opaque filament. Inside the object the IR-opaque material is selectively deposited to form an image.

What is that image? It can be a QR code or marks from a similar visual encoding system.

After printing the object would appear as normal, since the IR-opaque material is in the interior of the object. However, it would be “readable” by suitable IR cameras, including many mobile phones.

Here is a short video showing some actual examples of how this could be used:

This technology would appear to be implementable on many current 3D printers, including inexpensive desktop models, there would be some limitations. Objects would have to be 3D printed in IR-translucent materials, greatly restricting the available options. There does not seem to be many such materials on the market, although this could change in the future.

It’s also possible that some pigments used in common 3D printer filaments could be IR-opaque, thus disqualifying them from use in this mode.

Nevertheless, this technology has proven the concept.

While that’s the end of the technology developed here, what’s most interesting is the speculation on where this could lead.

We may be seeing a future where many objects are produced using additive approaches. Now imagine if those objects are routinely “stamped” with unique IR invisible codes. If that happens, then any typical scene would have multiple codes visible to a mobile device.

Each code could be used for any imaginable application. For example, a networked light switch could offer an “ON” code and an “OFF” code.

This could make EVERY object smart, even if they have no electronics within.

I’d like to see this capability built into today’s slicing systems so that more experimentation can be done by larger groups.

Via MIT