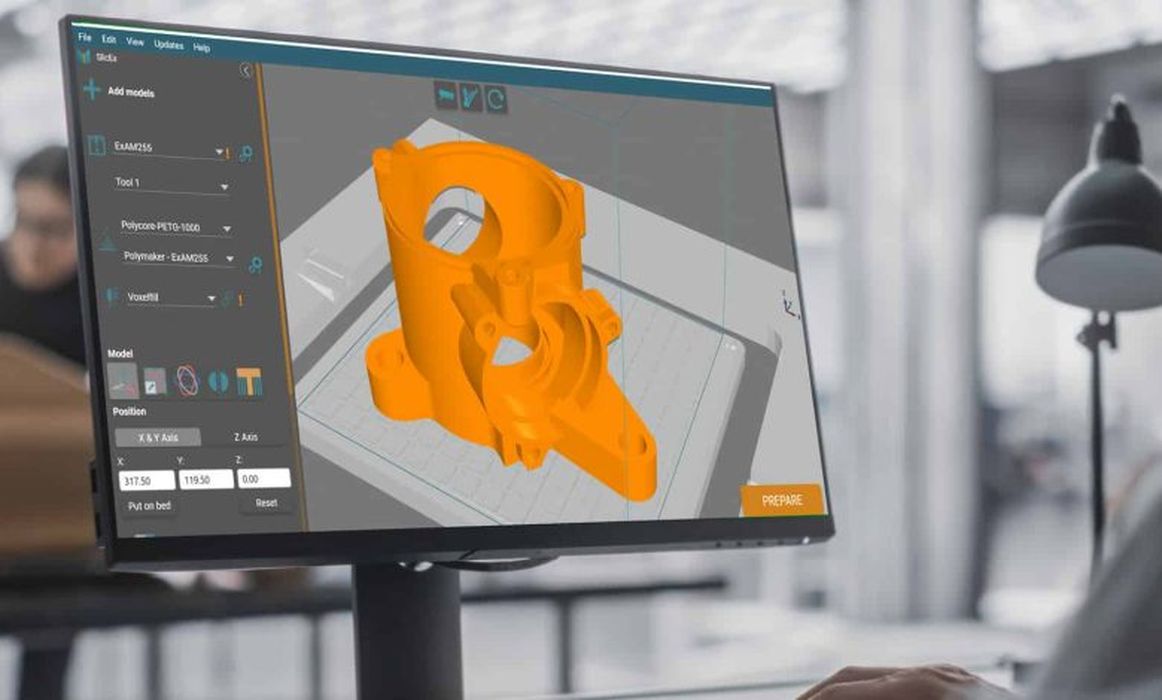

Via the SlicEx slicing software and an integrated plugin for ExAM printers.

The German material extrusion hardware manufacturer AIM3D and the Danish software company Create it REAL are partnering to integrate the patent-pending Voxelfill print strategy in a dedicated software solution. AIM3D has taken a new approach to overcome inhomogeneous strengths and scores with defined selective densities in the component.

The partnership around Voxelfill and capability development will be realized through a dedicated slicing software solution, SlicEx, and an integrated Voxelfill plugin for AIM3D’s ExAM printers.

The objective is to enable the additive manufacturing industry to overcome the disadvantages in terms of tensile and bending strength and very brittle behavior along the Z-axis. The Voxelfill process is particularly suitable for the 3D printing of plastics and fiber-filled plastics.

It is also suitable for the 3D printing metal and ceramic components using the CEM process. In general, there are great advantages for AM by leveraging the higher construction speed and the filling across layers.

AIM3D’s CTO, Clemens Lieberwirth, expressed his satisfaction with the collaboration, stating, “Create it REAL offers not only powerful and user-friendly software but also first-class support. The Create it REAL team is always ready to help, answer my questions, and resolve my concerns. We appreciate the fast and professional communication as well as the open-minded teamwork.”

Clemens Lieberwirth further emphasized the benefits of the collaboration, stating, “The reason why we chose to partner with Create it REAL was their flexible business model based on fair and transparent pricing, an existing product with the opportunity for deep user-driven adjustments and add-ons. We are very happy about the partnership with Create it REAL and would recommend them to anyone looking for a reliable and advanced 3D printing software solution.”

Read the rest of this story at VoxelMatters