Ai Build announced they’ve received a significant investment, and there’s an interesting twist to the story.

What is Ai Build? They are a London-based software startup that produces a cloud-based, AI-powered manufacturing platform.

Ok, but aren’t there other cloud-based systems of this type? Not really, it turns out, as Ai Build focuses on additive manufacturing at an industrial scale.

They believe that while most manufacturers in theory see benefits to use of 3D printing, in practice they get bogged down with the series of complex tools that their staff must master in order to successfully execute print jobs. This could be a significant barrier to the use of the technology at scale.

And scale is exactly where the major 3D printer manufacturers want to be.

Ai Build produces AiSync, their cloud system. Here’s how they describe it:

“AiSync accelerates and automates the creation of even the most advanced, multi-axis toolpaths via a single, intuitive UI.

Our intelligent AM platform replaces manual coding with visual programming, to completely simplify toolpath generation.

A digital twin provides full visual build simulation and collision avoidance. Also equipped with powerful reporting and analytics, the entire 3D printing process is optimized and fully repeatable.”

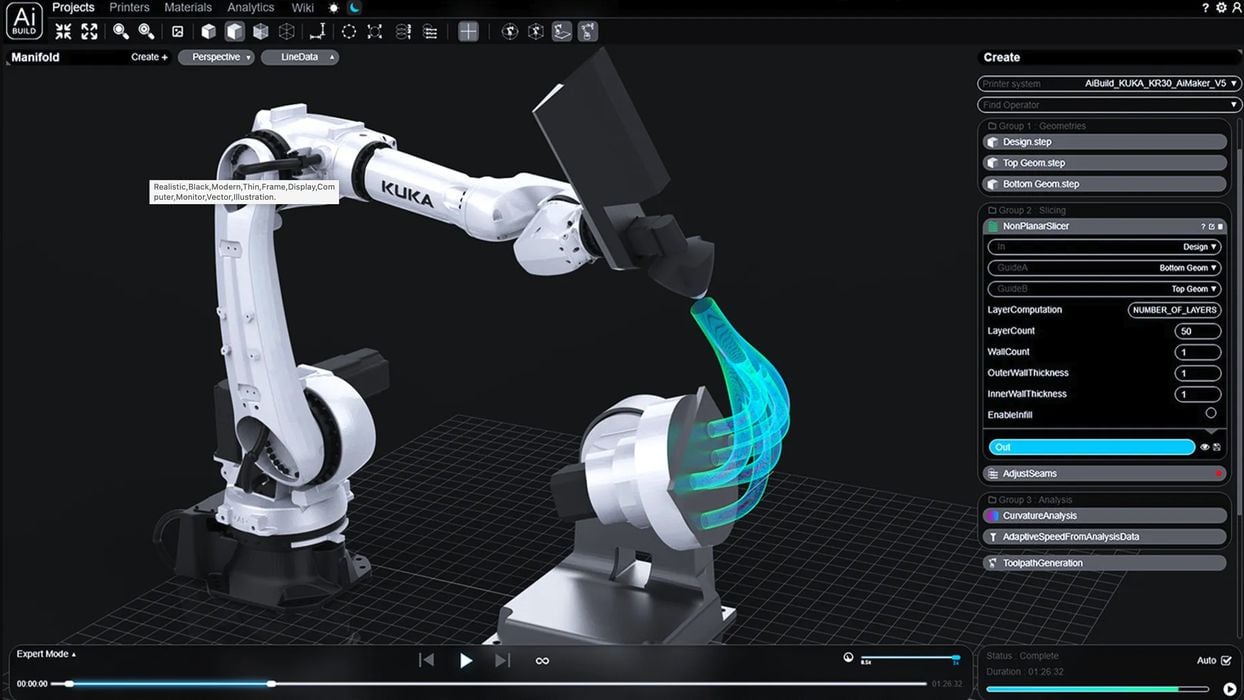

At top you can see a screenshot of this tool in action, where it has developed a non-planar toolpath for a robotic 3D printing system using a Kuka robot.

That’s correct: AiSync can generate highly complex toolpaths beyond mere layer-by-layer setups. In fact, they say they can generate multiplanar, segmented, 45 degree and conformal toolpaths, along with adaptive speed control. I am not aware of any other slicing tool that can do this.

However, the most important feature of AiSync seems to be its single interface that can lead the operator through job preparation and execution without the need for interaction with other complex and potentially confusing tools.

AiSync also includes an unusual AI-based chat system to interact with the system, ideal for less experienced operators. The video above shows how it works.

Now we learn that the company has just received a huge investment round of US$8.5M. The company explained how it will be used:

“Ai Build will use the funding to accelerate its product roadmap, allowing it to onboard more customers with higher levels of automation and AI capabilities. Investment will also enable the team to expand into North America by opening a subsidiary in the US, and to continue its expansion in Europe.”

But here’s the twist: the investment round was sourced from their existing investors, including Superseed, ACT Venture Partners, Atlas Ventures (UK), Seedcamp, and one new investor: Nikon.

Hold on, Nikon the optical company?

Yes, but there’s more: this isn’t the first step Nikon has taken into the world of 3D printing. Some months ago they announced plans to acquire metal 3D printer manufacturer SLM Solutions.

SLM Solutions has recently focused on larger-scale industrial metal additive production, particularly with their enormous NXG XII 600 twelve-laser system.

Now we see Nikon investing in a software company that should supercharge industrial activity in the additive manufacturing space. It seems there is a pattern emerging here.

As far as I can tell, there doesn’t seem to be a move to restrict Ai Build’s software to Nikon’s 3D printing operations, and that is in line with other recent software acquisitions by hardware manufacturers, such as Oqton by 3D Systems.

It may be that Nikon may increase their investment in Ai Build in the future, so we’ll keep watch on this scenario.

Via Ai Build