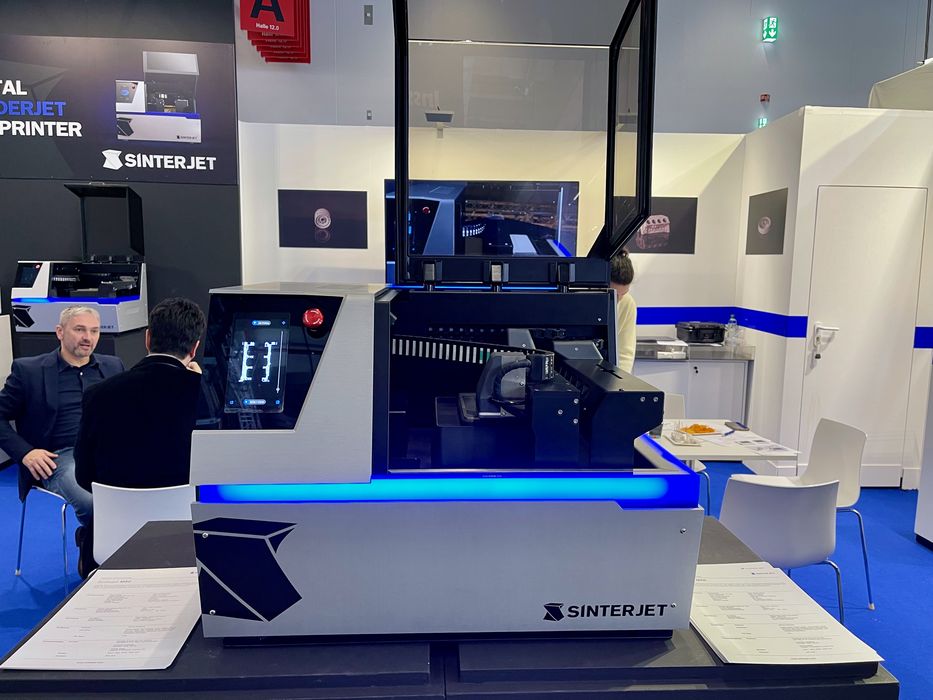

Sinterjet launched a new and inexpensive metal 3D printing system, the M60.

The company, based in Istanbul, has actually been around since 2012. Originally they produced SLS-style 3D printers, but eventually recognized that metal is where future action will take place.

They spent five years developing an inexpensive metal 3D printing solution, and it was launched at Formnext 2022.

Their research showed the market wanted a metal solution that was small and compact, user friendly, and most importantly, affordable. Unsurprisingly, it turns out that most companies don’t want to spend the millions required to set up complex LPBF metal 3D printing operations.

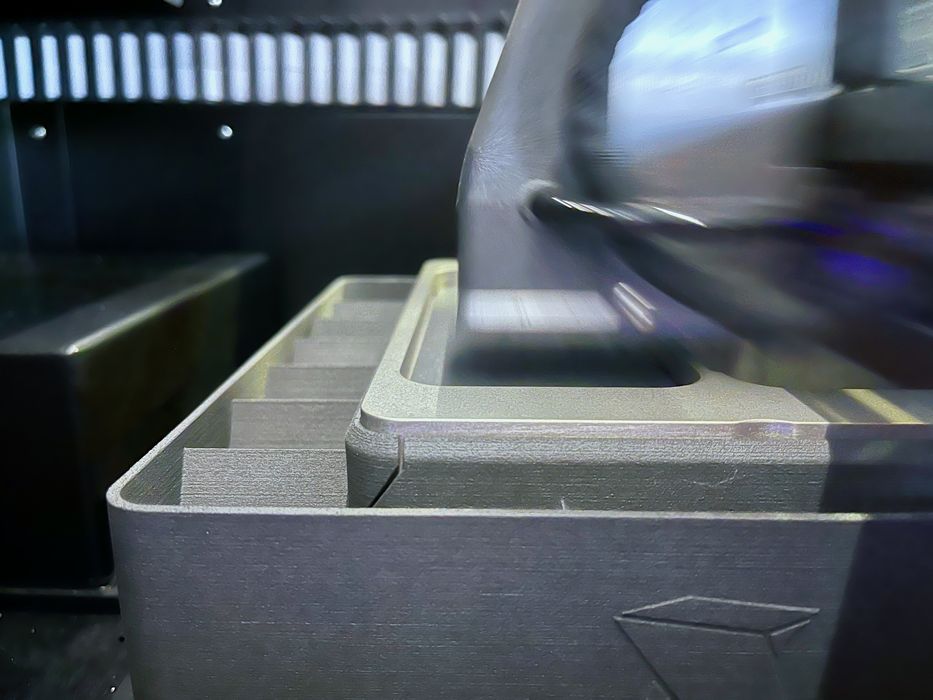

The M60 uses a binder jet solution, where a liquid binder solution is selectively deposited on powder layers until a complete object is prepared. Like all powder systems, no support materials are required, as the surrounding loose powder provides support for overhangs.

The printing process takes several steps:

- Binder is applied layer by layer as above

- The “BuildBox” is removed from the printer and placed in a curing oven

- Heat from the oven activates the binder to fuse the green part together

- The green part is removed and placed in a sintering oven at high temperatures to fully solidify the metal part

The build volume of the M60 is not large: 160 x 60 x 60 mm. However, the resolution of the binder jets is quite high: 1200 x 1200 dpi. The system is able to build at a rate of 50 cc per hour, which is pretty fast, particularly for such a small build volume.

The BuildBox concept allows for very rapid material changes: just change the box. I presume one could have many different materials ready to go by having the right number of BuildBoxes on hand.

In addition to the hardware, Sinterjet has developed an easy to use, near-pushbutton software approach. Operators simply select pre-defined profiles on the control panel to operate the M60, which then gets down to business.

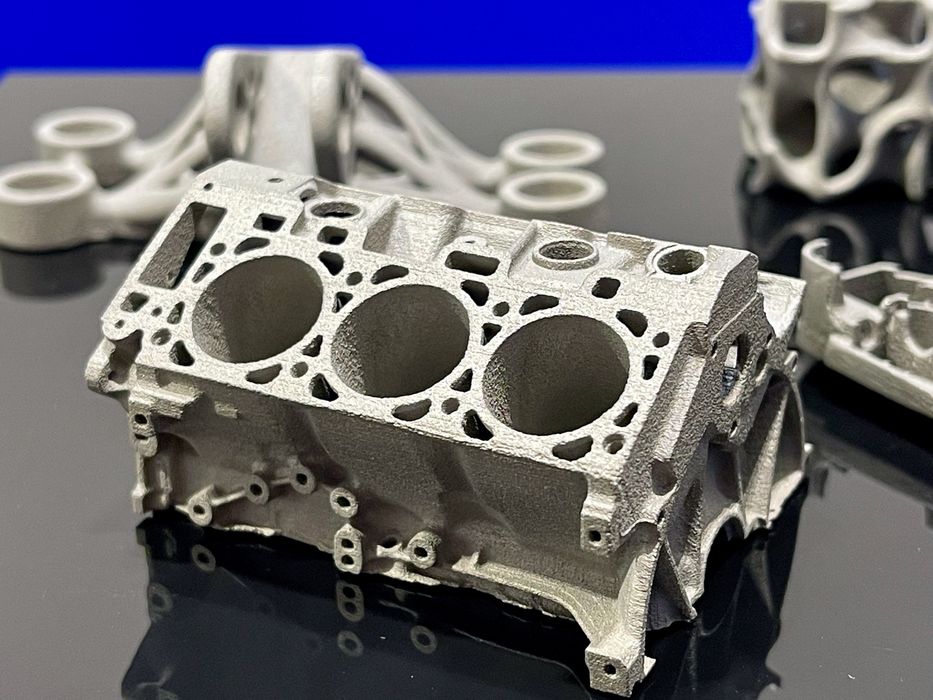

The print quality of parts made with the M60 are quite impressive, as you can see in these images. However, they are smaller parts due to the reduced build volume.

Sinterjet said the M60 system can produce complete parts in “only hours, not days”.

The M60 is priced €65,000 (US$68,000), so it is definitely less expensive than many metal 3D printing options. As of this writing, the company sells the equipment directly to European clients. If they succeed, I could easily see them partnering with resellers in other regions.

Via Sinterjet