Researchers at Imperial College London have devised a relatively inexpensive system to provide 5-axis 3D printing capability.

“5-Axis” is quite different from the typical cartesian 3D printing motions systems seen in virtually all commercial 3D printers. Typically prints are produced by building successive layers using one of the popular 3D printing processes.

However, a layered approach does have a number of disadvantages. One major issue is that the layer bonds are weaker than the material extruded, thus the layer lines become a natural break point should the part come under mechanical stress.

The other major challenge with the layered approach is that of overhangs. Material cannot be 3D printed in mid-air, so the usual solution is to provide support in some way. Sometimes the support is implicit, as in powder-based systems where the surrounding loose powder provides support, but in others explicit support structures must be built and later removed.

Support structures are required, yet highly undesirable: they require considerable manual effort to remove, consume material and often leave surface artifacts where they connected.

Personally, I try my best to reduce the amount of support required because of these problems.

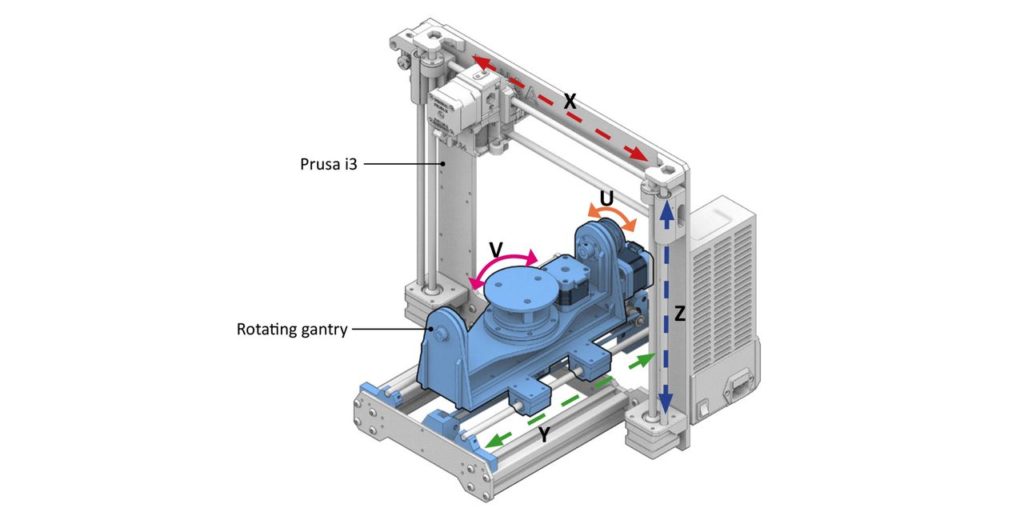

However, the need for support structures actually disappears when using 5-axis systems. In a 5-axis 3D printer the print can be rotated around two additional axes. This provides an opportunity to “turn it upside down” to allow for the printing of overhangs without the need for any support material.

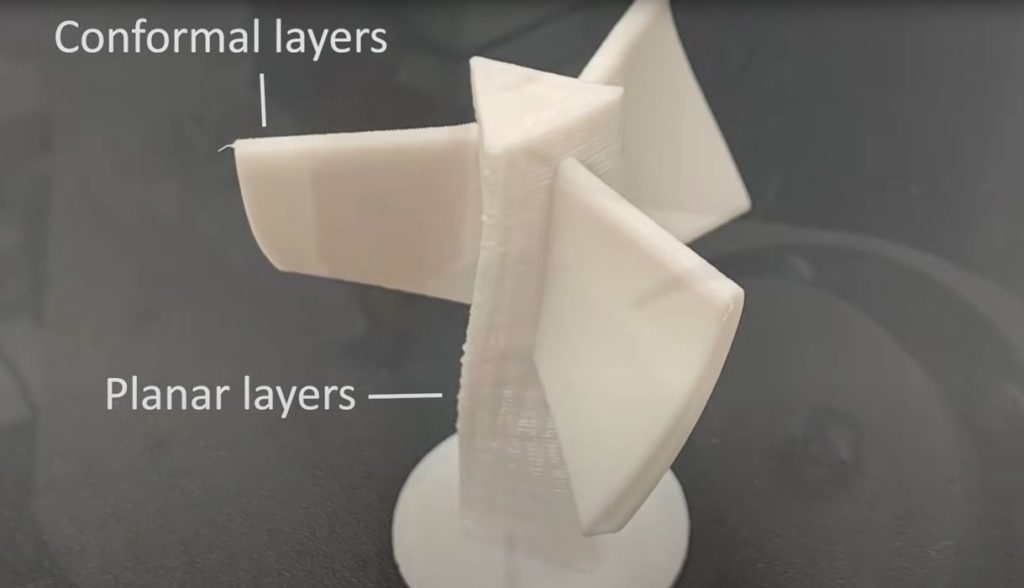

The other advantage of 5-axis 3D printing is that the layer lines are constantly changing, meaning there is no particular weak point: as the layer lines curve around, they are far stronger than straight, linear layers.

Why doesn’t everyone use 5-axis 3D printers? It’s because the cost of these systems has been quite high, sometimes requiring expensive robotic equipment and associated software. There are indeed a couple of 5-axis 3D printers on the market, such as those from VSHAPER and Hage, but they are priced at levels where only industry can afford them.

There have been attempts to modify inexpensive 3D printers to print in a non-planar manner, such as Gabriel Boutin’s experiments. While successful, this approach is only valid for a subset of possible 3D models.

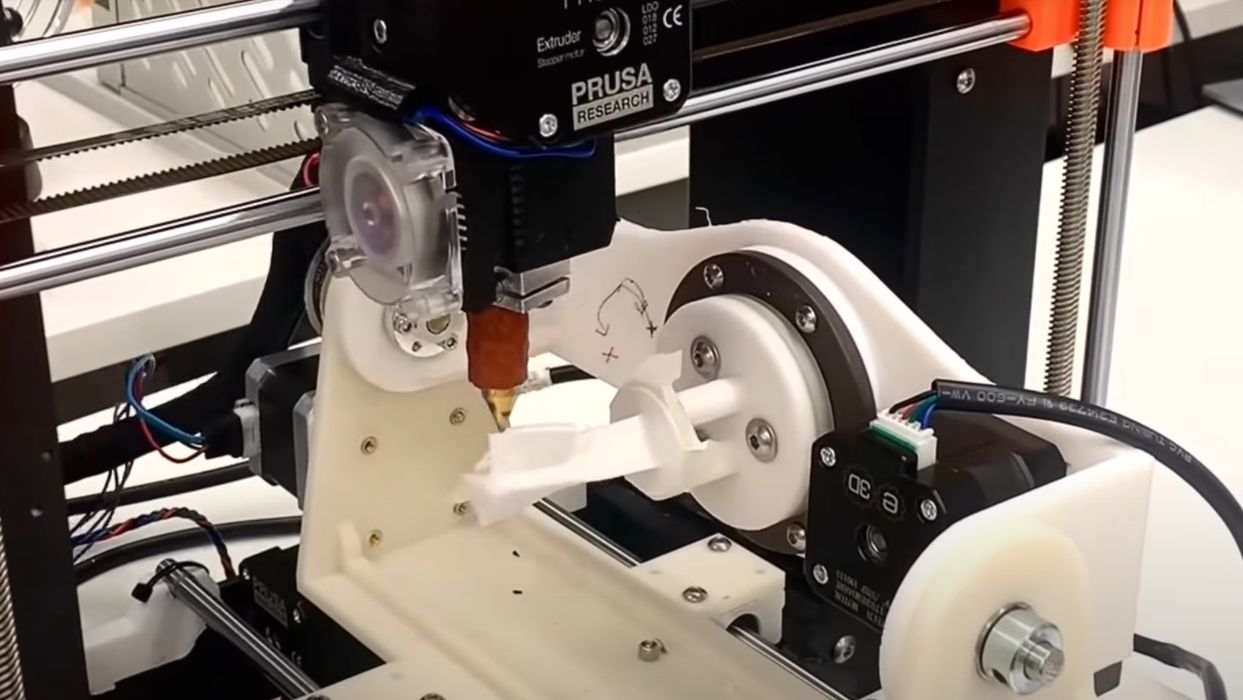

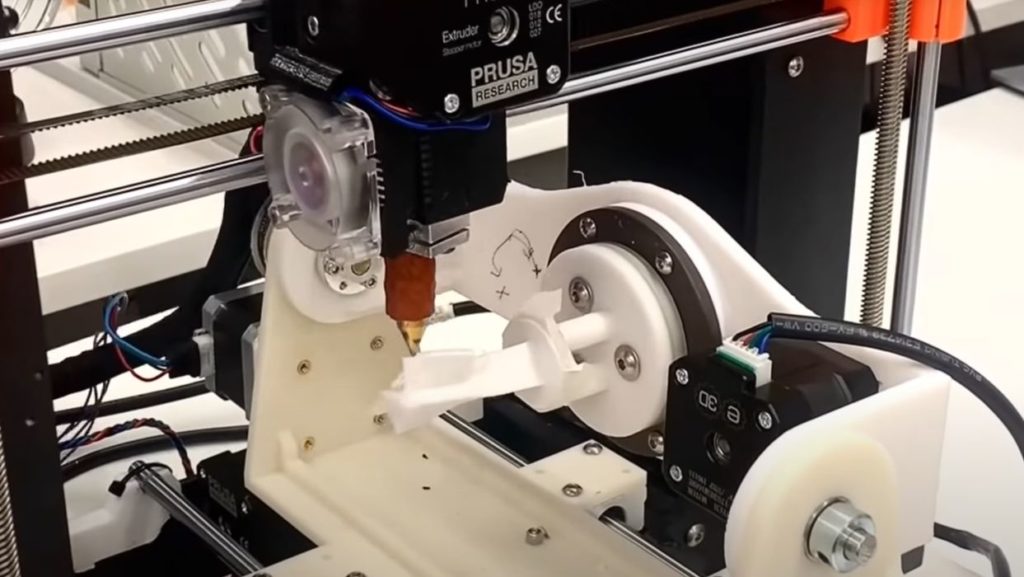

Now there’s a new approach that is truly 5-axis. The researchers, led by Freddie Hong, have developed a modification to a standard Prusa i3 desktop 3D printer that implements 5-axis functionality.

Even better, the work has been open sourced under the name “Open5x”.

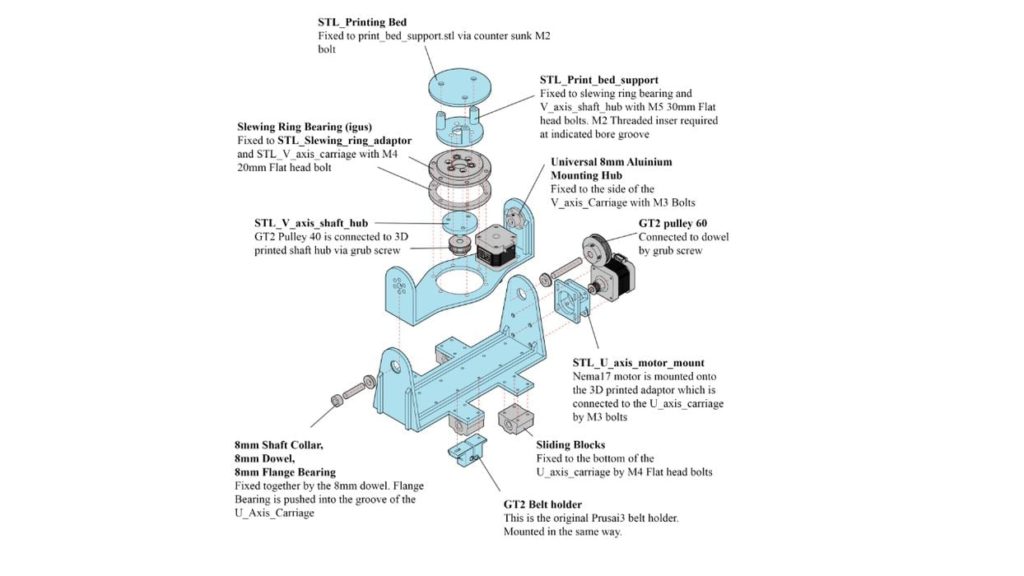

The modifications involve the replacement of the build plate with two new axes, combined with sophisticated software to coordinate axis movement. The hot end must also be extended to ensure it can reach into the non-planar print. You can see how it works in this video:

The work was described in detail in a scientific paper recently released, and a GitHub site will very soon provide all the details for reproducing this work, including part designs, software and circuitry.

As you can see in the video, the need for support structures is essentially eliminated, and parts produced should be notably stronger due to the eliminated of planar layers.

They have also demonstrated multi-material 3D printing, as the rest of the Open5x printer is the same as normal cartesian 3D printers.

While powerful, there are some concerns. First, the ability to 3D print larger items may be problematic: the bigger the part, the longer the hot end must be. There is almost certainly a practical limit to the size of objects printed on Open5x.

There is also appears to be no way to 3D print multiple objects in a single print job, since there is no “print plate”. The print begins at a point and extends from there.

Nevertheless, those minor issues are of less concern than the constant worry over support structures, which is resolved by Open5x.

At this time it would be possible to review the provided files and build an Open5x system for yourself. However, that is certainly going to be a considerable amount of work.

What’s likely to happen in the future is that someone will commercialize Open5x by using the concepts and designs to produce a packaged-up version of the system for purchase. This is commonly done, and is in fact how Prusa Research got their start long ago.

It would seem that in a short time you may be able to purchase your very own 5-axis 3D printer.

Via Freddie Hong