1000 Kelvin announced today they have established a very intriguing partnership with Fieldmade.

1000 Kelvin is a software startup that focuses on increased print quality and reliability. Their AMAIZE platform is powered by AI and acts as a kind of “co-pilot” for 3D print operators. What exactly does it do? They explain:

“One-stop shop AI software to predict near real-time print issues, perform corrections, and generate industrial-grade, ready-to-use print file specific to your machine.”

The software is trained using physics and manufacturing data collected by sensors from a large number of actual jobs. The output is corrected “print recipes” that raise the success rate and quality of jobs using them. Their target is to enable operators to achieve success on the “first try”.

That is certainly attractive to those doing additive manufacturing, as producing end-use parts requires highly consistent parts of quality within tolerances. That’s very difficult to achieve, and often requires squads of AM engineers to spend considerable amounts of time to work out the bugs before production can proceed.

Fieldmade is a Norwegian specialist in on-demand spare parts production and supply chains. They focus on digital warehouses, inventory analysis and implementation of solutions. They explain:

“With expert knowledge within the full spectrum of the applied additive manufacturing domain. From insights in supply chain logistics and business model development, to designing for additive manufacturing, topology optimization, qualification assessment and control, and process simulation, we are able to aid you in the world of additive manufacturing and digitalization.”

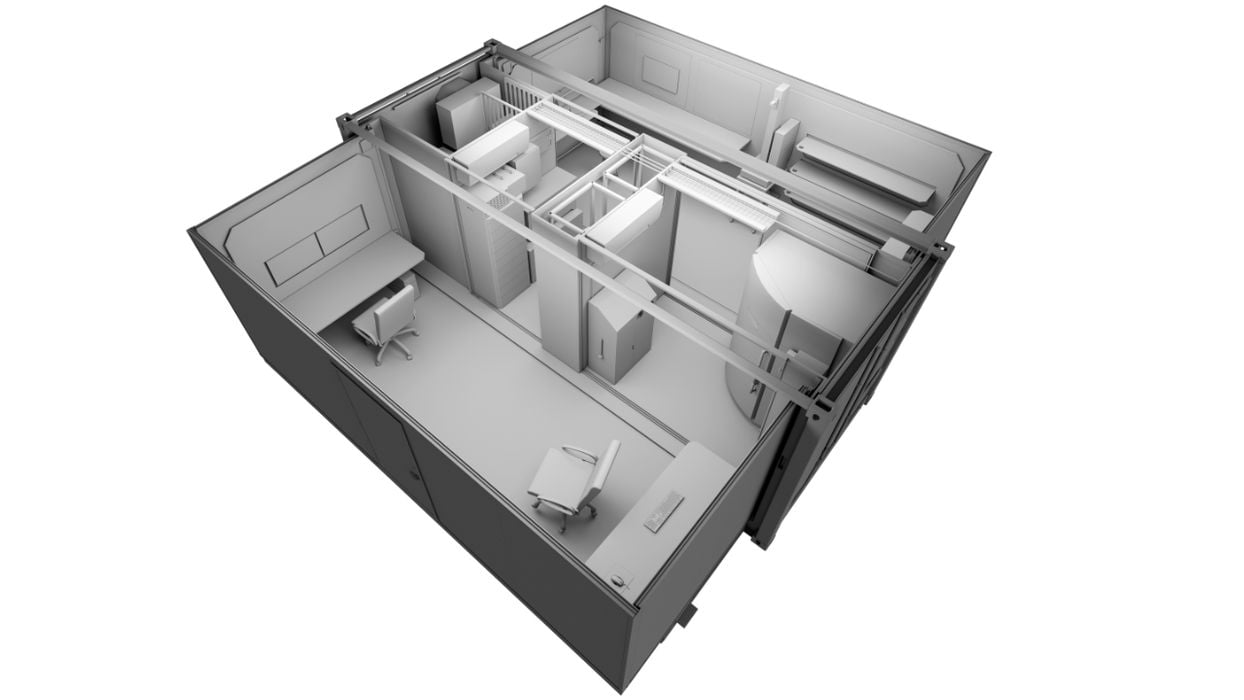

One of their products is “NOMAD”, a mobile manufacturing station that can be easily shipped by “air, sea and land”. There seems to be three NOMAD models, 01, 02 and 03:

- NOMAD 01: Prototyping and temporary spare parts

- NOMAD 02: Real time spare parts production

- NOMAD 03: Metal spare parts production

The idea is to drop a NOMAD system near the field of battle, where is can almost immediately begin producing required spare parts on demand. To make this work the digital inventory must be set up earlier. Fieldmade has been collaborating with several militaries on this technology, including the Norwegian Armed Forces.

The partnership enables bundling of AMAIZE with NOMAD, ensuring military operators are far more able to successfully producing spare parts in less time.

Fieldmade CEO Jostein Olsen said:

“Our vision is to make deployable 3D printing as easy as using a vending machine. The integration of 1000 Kelvin’s AMAIZE into our products is a significant step towards this goal.”

This is an interesting approach that we haven’t seen done many times before: bundling advanced software with a deployable solution. As we see more mobile 3D printing solutions emerge, it should become standard to include each and every component required, both hardware and software.

Via 1000 Kelvin and Fieldmade