Charles Goulding Jr. considers the future of nuclear energy and its acceleration via 3D printing.

High Stakes Debate

The risks of nuclear power are well known. Fukushima dumped huge amounts of radioactive material into the Pacific Ocean; Chernobyl created a 30km uninhabitable zone for up to 20,000 years.

Known also within the energy industry are nuclear’s exorbitant cost and waste disposal issues. Indeed, despite decades of U.S. nuclear power usage (20% of national electricity supply), the country has no set plan for permanent waste disposal.

On the other side of the nuclear ledger is the carbon clock ticking inexorably toward parts per million levels that scientists believe would be catastrophic. As each day passes, the decision to deploy advanced nuclear technology gets made through climate inaction.

To be sure, many would say an affirmative decision on nuclear should be made anyway. These include advocates of technologies like small nuclear reactors purported to be superior to traditional plants.

Taking the Temperature of Advanced Nuclear

Small nuclear reactors are, to start, smaller. They are known as small and medium reactors (SMRs), though the acronym usually applies only to small reactors that generate roughly 300 MWe.

According to the World Nuclear Association, SMRs are “designed for serial construction and collectively to comprise a large nuclear power plant…. A subcategory of very small reactors – vSMRs – is proposed for units under about 15 MWe, especially for remote communities.”

The smaller size of SMRs, advocates claim, confers a host of benefits. For one, the plants are cheaper and faster to make, though still far from inexpensive ($1bn each).

Plant design is also more integrated. Integrated, modular plants are safer, it is argued, because of a reduced likelihood of any one part malfunctioning, whether for internal reasons (Chernobyl) or from an external stressor like flooding (Fukushima). (When parts malfunction, the reactor’s ability to cool itself may be compromised, leading to over-heating and eventual meltdown.)

When emergencies do happen, SMRs may be more adept at crisis management.

“Even under worst case scenarios, where we lose all off-site power, the reactor will safely automatically shut down and remain cool for an unlimited time,” said José Reyes, co-founder and CTO of the SMR firm NuScale.

Pebble Beds

Pebble bed reactors, a type of SMR, may have removed the risk of over-heating entirely. At the foot of the reactor rests of bed of enriched spheres. The spheres are the size of a billiard ball and form a protective shell around the uranium-enriched within. Helium captures heat from the balls and then enters a steam generator for electricity.

According to the DOE, “Each pebble remains in the core for a little more than three years and are circulated through the core up to six times to achieve full burn-up. The spent fuel is then placed directly into dry casks and stored on-site—without the need for interim or active cooling.”

The DOE has already committed more than $30 million to pebble bed firms like xEnergy. Private firms, working in conjunction with public labs like Oak Ridge National Lab (ORNL), hope to have these modular reactors operational within the decade.

More Good News for SMRs

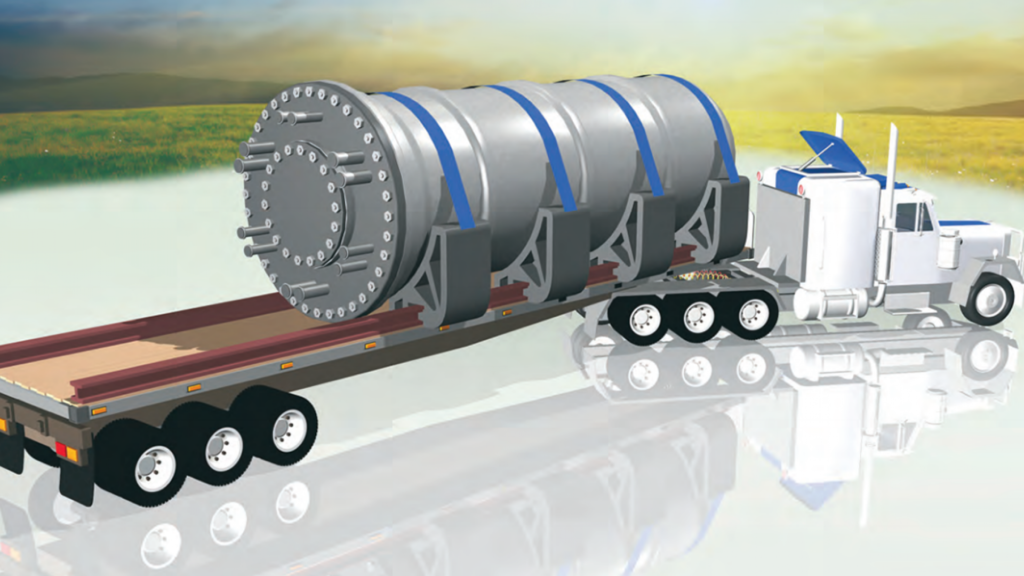

Additional SMR benefits, according to the Department of Energy, are siting flexibility (smaller site placement where larger plants cannot go); efficiency (through faster construction and through better compatibility with clean energy sources like wind and solar), and job creation (in areas like manufacturing, construction, and maintenance at a wide range of site locations).

Insofar as the nuclear issue is a political one, moreover, it is notable that new advocates have emerged. In particular, the women-led Good Energy Collective has begun promoting advanced nuclear technologies, offering perspectives on how these technologies conform to progressive goals. Given left-wing resistance to nuclear power, the Collective’s advocacy may be exactly what the industry needs.

The Role of 3D Printing R&D

With ORNL scientists now able to 3D print core reactors, additive manufacturing can play a dominant role in the industry going forward. Knowing this, the DOE has been aggressively disseminating its 3D printing reactor IP to private firms like NuScale.

Not only will 3D printing help lower production costs, it will also help make SMRs quicker, slashing lead times from years to months. In addition, the integrated design of SMRs can get a significant boost from 3D printing’s ability to manufacture custom, integrated parts.

The list of SMR components with 3D printing applicability includes: motors, coolant circulation pumps, control rod drive mechanisms, pressurizer, in-core instrumentation, and entire SMRs.

What’s more, the infrastructure and expertise needed for SMRs has applications outside of power generation. According to the DOE, “These advanced reactors, envisioned to vary in size from tens of megawatts up to hundreds of megawatts, can be used for power generation, process heat, desalination, or other industrial uses.” These additional applications, including desalination, have their own strong ties to 3D printing.

All told, the 3D printing R&D opportunities for advanced nuclear and related fields are wide-ranging and robust.

The Research & Development Tax Credit

3D printing firms innovating in technologies that touch on desalination can avail themselves of the federal R&D tax credit to help subsidize their research efforts.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and for the first time, pre-profitable and pre-revenue startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

The nuclear debate is by no means settled. What is clear is that the level of atmospheric carbon dioxide will continue rising absent drastic action. To achieve rapid decarbonization, the safety and other benefits of advanced nuclear may well tip the scales in favor of pebble bed reactors and other SMRs.

3D printing’s cost, customization, and parts integration benefits likely make it crucial to SMR production at scale. Firms engaged in such efforts can use tax credits and other incentives to assist in an energy revolution that must be safe, fast, and effective.