Addup joins the orbital 3D printer club with the latest launch to the International Space Station.

3D print technology is of extreme interest to NASA and other space agencies. They’re seeking ways to reduce the cost of operations, which is largely governed by the price of placing objects in orbit via expensive rockets. If parts are lightweight, that’s good.

But an even better way is to not send the parts at all. That’s the lightest possible approach.

The concept they’re heading towards is the ability to 3D print any parts required on the space station when required. While the material for printing must be launched, there would be far less need to stock spare parts. Many of these would be unused, and that’s wasted launch capacity.

Because of this need NASA has done considerable experimentation with 3D printing in space. The first experiment was done several years ago when Made In Space was able to ship a prototype FFF device to the ISS. After some months of testing, it was determined that the parts produced were pretty much the same as those made on the ground.

That opened up ways to create on-demand parts production, which is still in development. However, the experiment only used polymer materials. Spare parts must often be made from metal, however.

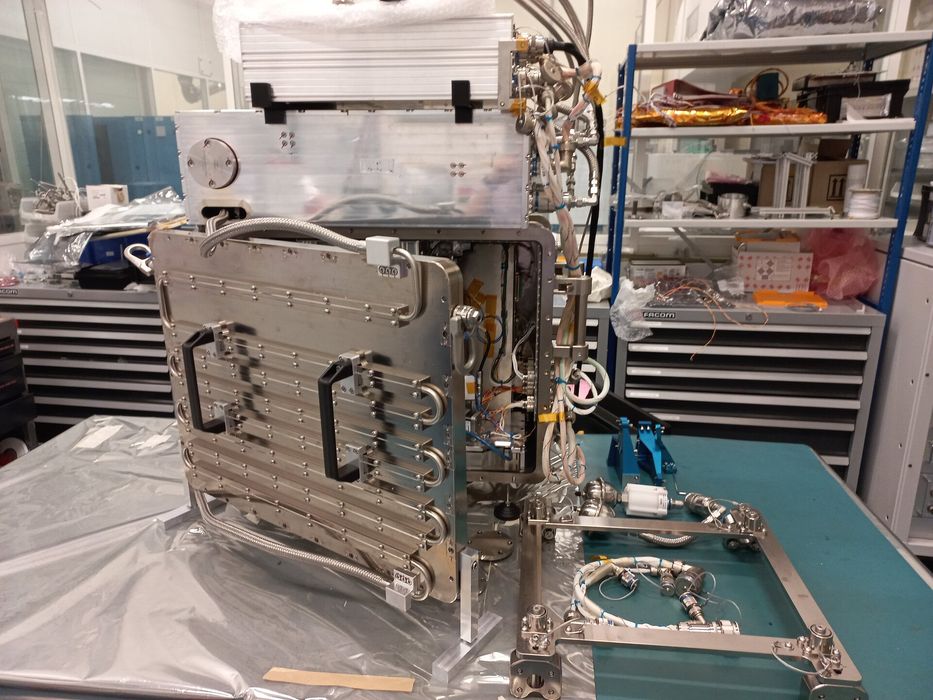

That’s where the new experiment from Addup and Airbus comes in. They’ve jointly developed a unique metal 3D printer that is designed for use in the microgravity environment of the ISS, as we reported a while ago.

Now that 3D printer has been delivered to the space station. Addup explains:

“ The metal 3D printer was designed to evaluate the capabilities and performance of additive technology and to perform metal disposition in 3D under sustained microgravity conditions. On Tuesday, January 30, 2024, the Metal 3D Printer was successfully launched by NASA Mission NG-20 towards the International Space Station. Printing operations are expected to start in late February or early March.”

It’s my understanding that this 3D printer uses a form of DED printing, Direct Energy Deposition. This is a common metal 3D printing process, and likely avoids the use of metal powder. Powder would be a nightmare in the weightless environment of the ISS, where it could contaminate electronics or people, let alone stay still on a print bed.

Does this mean astronauts will be printing spare parts? Not at all, as this is just an experiment to see if the process works at all. That’s a requirement before a production printer could be designed to meet the need for producing spare parts. Here they’re basically testing the printing process and procedures.

The experiment involves 3D printing four metal sample objects — that’s all. Yes, this is a printer designed to print only four parts, one time only. Note the rather small size of this unit in the image at top.

Those parts will then be taken back down to Earth for examination. This will determine if there are any differences in DED operations in a weightless environment.

My suspicion is that there will be little to no difference. If that’s the case, then NASA has another technology that could be used in future missions. They may request manufacturers to develop a metal 3D printer that is sized for spare parts production for later installation.

However, there’s a bit more to the story here.

The ISS has been flying around our planet since 1999, and it’s now 25 years old. Operating partners have agreed to keep it going later into this decade, but time is working against them. Eventually the ISS will become obsolete and risky to operate as parts degrade.

Why develop a metal 3D printer for a space station that will only be around for a few more years? That’s because there are MORE space stations in the works. It seems that in only a few years new rockets will be able to haul massive space stations into orbit at much lower cost.

There could be quite a few of these new-style stations orbiting the Earth in the not-too-distant future.

Many of them will no doubt want to 3D print metal spare parts, and that’s where this technology will be going.