I’m reading an interesting LinkedIn post by Kyle Harvey about additive manufacturing crossing the chasm.

Harvey is the Additive Manufacturing Business Manager at Extol, a Michigan-based manufacturing technology company.

The “chasm” Harvey refers to is a classic business concept developed by Geoffrey A. Moore that explains why some technological companies seem to stall during their growth phase rather than continue their trajectory upwards.

The essence of the concept is that early adopters are far more willing to take chances with technology and withstand uncomfortable and challenging situations than the general public. This often fools startup companies, who unknowingly believe their initial success — based on early adopters — will carry them forward into the larger population.

In truth, the general public is far less tolerant of technological oddities, and companies that don’t address that simply stall out. Usually they are overtaken by other companies that do realize this and take action to redesign the technology to be more amenable to the general public.

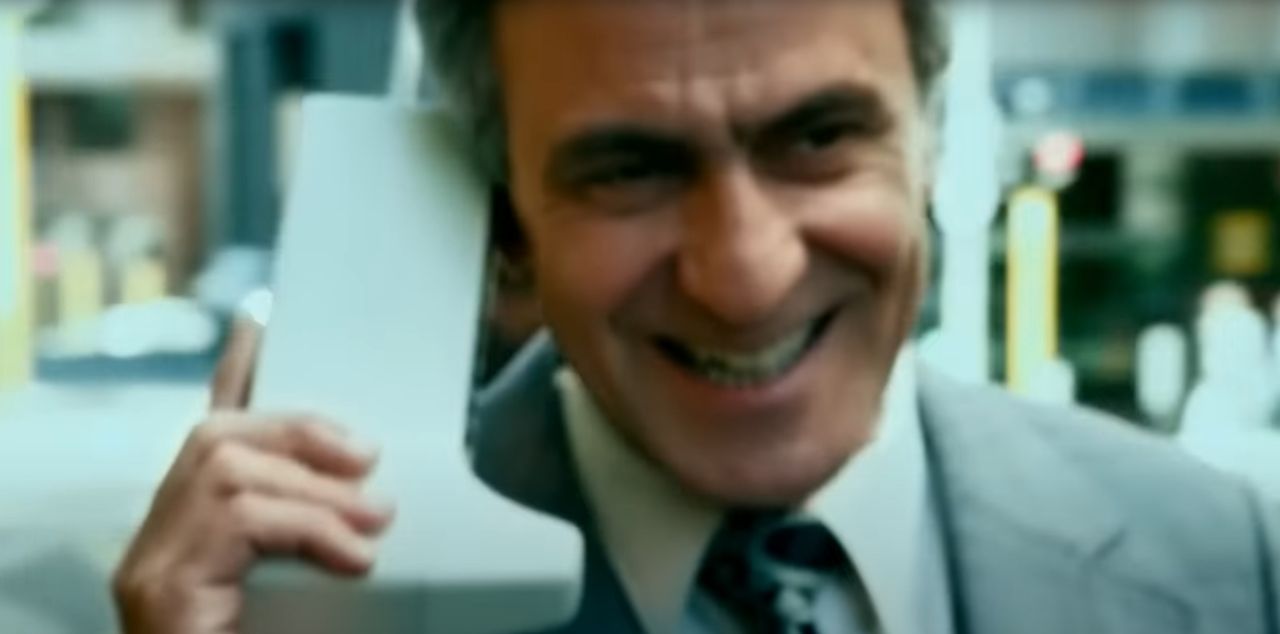

As an example of this, consider the now-ubiquitous cellphone. There was a time when very few people used them. Why? There were plenty of reasons: no where to buy them; they were massive; they had few functions; very limited coverage; high prices; etc. It’s not surprising hardly anyone used them back in the 1980s.

But now everyone has them. What happened? Someone (in this case Apple and RIM) somehow figured out how to address the needs of the public and the technology then launched into orbit, crossing the chasm. The companies that didn’t do so, died.

Back to 3D printing.

In the past year or so there has been little visible progress in the industry overall. Revenues have been mostly flat, valuations down, and companies disappearing or merging with others. There’s also plenty of discussion about why this has happened to a technology that at one point was hyped to the max.

Some propose that “additive manufacturing can’t cross the chasm”.

That’s possible, but Harvey has an answer to that proposition:

“Analyzing the innovation curve of additive manufacturing industry as a whole is the wrong focus. The technology itself is only a method for manufacturing.

Instead we should seek to understand innovation curve for each of the individual applications that are enabled by additive manufacturing. If you do that, you find that not enough of the individual applications have crossed the chasm to follow through on the exorbitant promises and hype of the AM industry as a whole.”

This is the correct answer: there are plenty of fully adopted applications, including dental aligners, rocket engines, prosthetics, certain aerospace parts, and many more. You can’t say the entire industry has stalled when there are multiple specific successes.

This is how it goes with a technology: a great deal of exploration must occur to find the right kind of applications. Many of those expeditions fail, but in doing so define the limits of what can and cannot be done.

What seems to be happening, however, is that some investors believed that the technology could address some larger scale applications in manufacturing, but experience has now shown that is quite challenging. They are obviously disappointed, but we now know something we didn’t before: to capture those applications, something must be different.

That’s why I get excited about failures: they define a technical challenge at others will attempt to solve. Many will fail, some will succeed.

The bottom line here is that we may have reached the limits of the current 3D printing technology in some applications. This implies that we need NEW technology to open up those applications.

Let’s get to it!

Via LinkedIn