Charles Goulding and Andressa Bonafé examine the state of bioprinting with a look at recent developments.

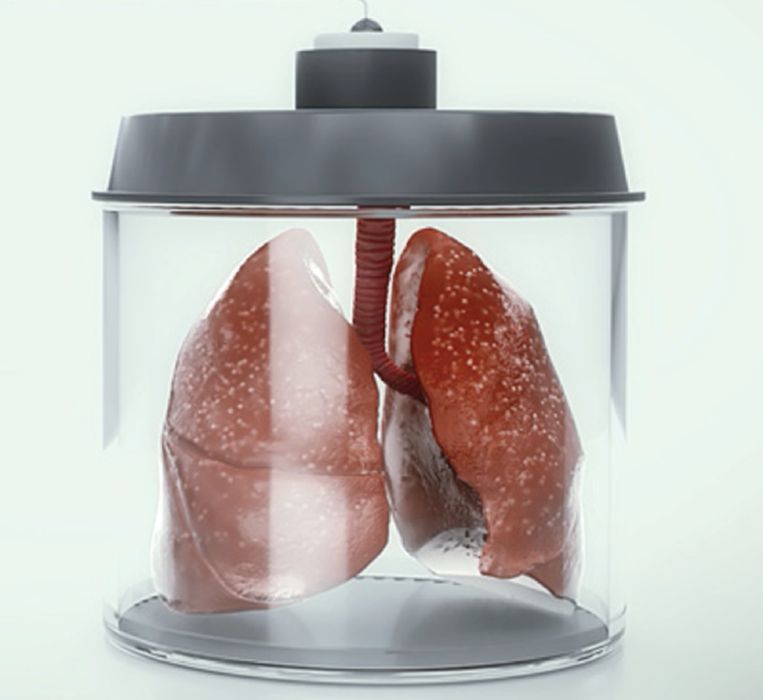

Throughout the globe, a growing number of companies and research institutions seek to advance biotechnology with 3D printing. The viability of lab-grown organs is increasing, as researchers improve techniques that will allow for the printing of cells with embedded blood vessel networks. Maryland-based biotech United Therapeutics stands out in the quest to solve the organ-supply crisis, particularly the 3D printing of organ scaffolds that could potentially be filled with a patient’s own stem cells and transplanted into their body. In partnership with 3D Systems Corporation, United Therapeutics recently unveiled a lung scaffold, characterizing it as the world’s most complex 3D printed object.

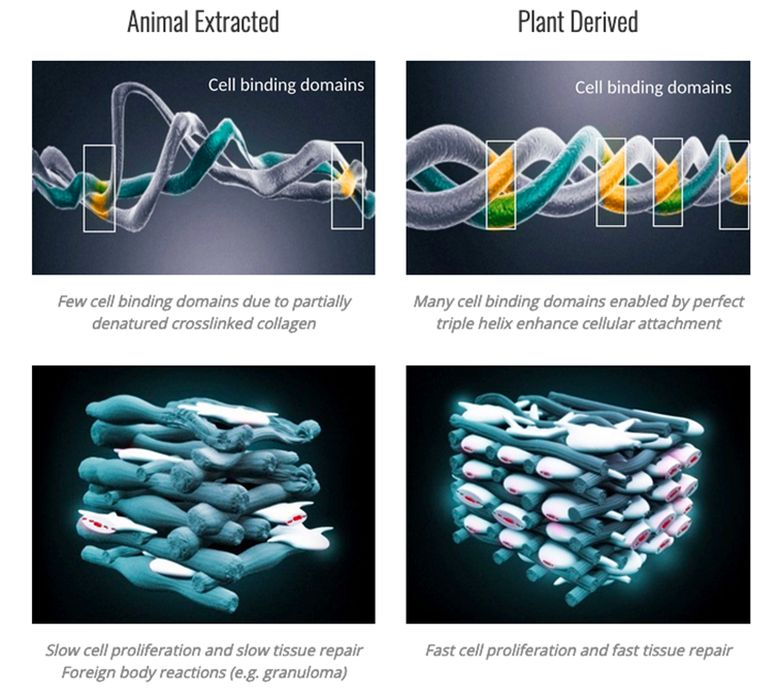

In July 2021, we reported on another exciting prospect for bioprinting – CollPlant Biotechnologies’ partnership with 3D Systems and their work on the development of bioprinted solutions for improved breast reconstruction procedures. The Israeli regenerative and aesthetic medicine company has developed a unique technology for mass production of recombinant human Type I collagen (rhCollagen), which is identical to the collagen produced by the human body. Extracted from plants rather than humans or animals, rhCollagen’s plant-based nature allows its conditions to be precisely controlled for homogeneity, improved biofunctionality, and reduced risk of immune response.

Yet another more recent development in bioprinting is Inventia Life Science expansion to the U.S. Committed to advancing 3D printing technology as a means to revolutionize biomedical research and drug discovery, the Australian biotech recently opened its first U.S. office and facility at The Innovation Space™, in Wilmington, Delaware.

Inventia manufactures 3D bioprinting machines that create human tissue for research and therapy. By offering cell models that closely and predictably replicate real human tissue structure and behavior across a range of disease states, the company opens the way for highly complex, world-class research and discovery.

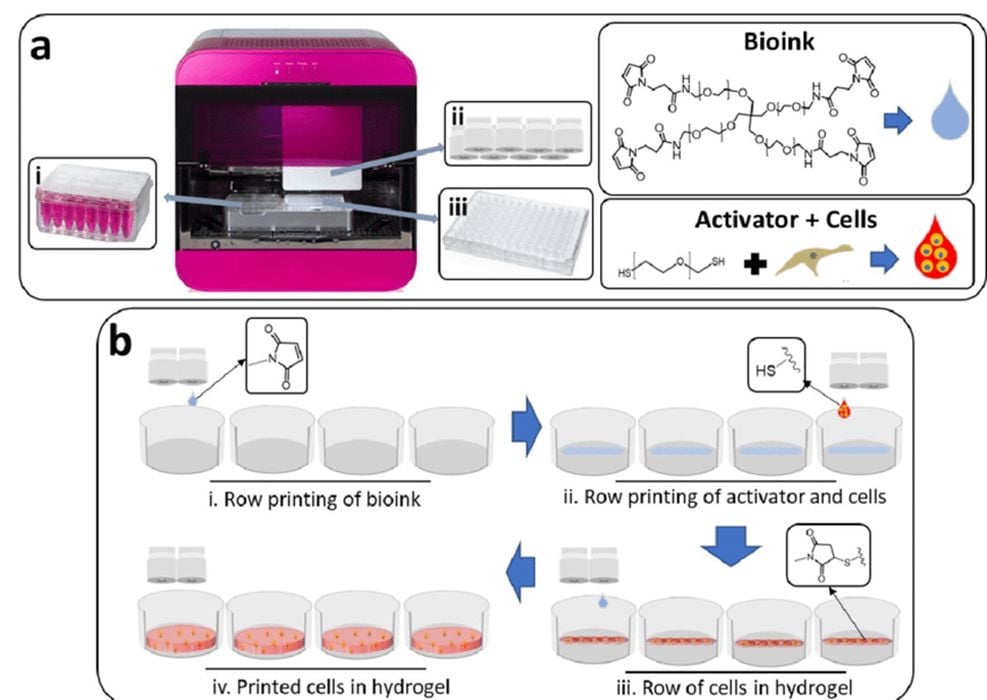

Aiming to advance fast, scalable, and reproducible printing of 3D constructs, Inventia created RASTRUM™, a proprietary platform that encompasses drop-on-demand bioprinting technology, an expanding library of printable matrices, and custom protocols for specific applications. With a select-print-use approach, the award-winning platform allows for the creation of 3D cell models in standard well plates that easily integrate with existing experimental workflows.

Users select from a library of proprietary RASTRUM™ matrices and 3D cell models, thus saving time that is usually dedicated to 3D modeling or hydrogel engineering. An automated workflow is then implemented for efficient and reproducible printing of 3D cell models. The resulting models are ready to use and compatible with standard culture and downstream analysis workflows.

Compared with other 3D bioprinting technology, RASTRUM™ gives researchers enhanced control over the types of cells being printed and the environment in which they will grow. The ability to create precise 3D constructs with multiple cell and/or matrix components enables probing of specific cell-cell or cell-matrix interactions in a controlled and quantitative way. It also allows for innovative experimental design and rapid testing of multiple variables, which could greatly contribute to advancements in fundamental explorative biology.

With very diverse applications, RASTRUM™ has helped advance drug discovery and biomedical research in a variety of areas. Its matrices support a wide range of tissue cell types, from diseased to healthy cells (being compatible with breast, lung, brain, liver, skin, pancreas, prostate, and ovarian tissue cell types). In addition to greatly accelerating drug discovery processes, the platform opens the way for a paradigm shift in patient care, creating the potential to screen a range of drugs against an individual patient’s tumor cells in vitro, combined with genomic analysis.

A Growing International Presence

Founded in 2013, Inventia is headquartered in Sydney, Australia. The company’s innovative approach to bioprinting has experienced growing international demand, with four out of the top 10 global pharmaceutical companies using RASTRUM™ for their drug discovery programs, according to Dr. Julio Ribeiro co-Founder and CEO, former Sales Manager for Australia and NZ for Sigma-Aldrich.

In December 2021, Inventia announced the closing of a US$25M Series B funding round, which will be used to market its RASTRUM™ 3D cell culture platform worldwide and grow its team from 36 to 150 employees by the end of 2024. The launching of U.S. operations is part of this initiative and is expected to enable closer support to the growing North American customer base.

While other biotech markets were considered (including Philadelphia, San Diego, and Texas), The Innovation Space™ in Wilmington, Delaware, offered the right combination of laboratories, talent, geography, and access to customers. The not-for-profit innovation ecosystem comprises 130,000sf of state-of-the-art lab and office space with access to cutting-edge equipment alongside a variety of entrepreneurship programs and opportunities supporting startup growth.

While Inventia’s expansion to the U.S. promises to help the company take full advantage of increasing global interest in 3D bioprinting, it could also open the way for greater support of R&D activities through the Research & Development Tax Credit described below.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The opening of Inventia’s first U.S. office and facility brings exciting new perspectives and promises to allow the company to take full advantage of growing global interest in RASTRUM™. The R&D Tax Credit available to support U.S.-based qualified activities could increase Inventia’s and other biotech companies’ chances of success in a highly competitive environment.