SPONSORED CONTENT

Recently we had the opportunity to tour the LulzBot 3D printer production facility.

LulzBot is manufactured by FAME 3D, based in Fargo, North Dakota. FAME 3D took over the LulzBot assets of Aleph Objects back in 2019, when Aleph Objects was about to shut it all down.

According to FAME 3D CEO John Olhoft, 28 semitrailers hauled everything from Colorado to North Dakota to restart the operation. They moved not only parts, tools, software and files, but even office chairs and tables. Literally the entire operation was moved in only a few days.

After some setup and rapid hiring of fifty brand new staff with the assistance of the North Dakota governor, the Fargo operation was soon able to produce the first LulzBot 3D printers.

Our team was recently able to visit the site and take a close look at operations, which were quite impressive.

The first thing you see when you enter the factory is actually a retail 3D printer store, where FAME 3D sells 3D printers, materials and LulzBot merch to locals. It wasn’t particularly busy when we dropped by, but the primary purpose of the site is to manufacture and ship 3D printers.

There’s a small museum of LulzBot devices, containing equipment made by both Aleph Objects and FAME 3D.

FAME 3D seems to be successful due to their ability to make quite a few of their own parts onsite. For example, they build their own wire harnesses, rather than ordering them from overseas and not receiving them at all, as has been the case for some other 3D printer manufacturers.

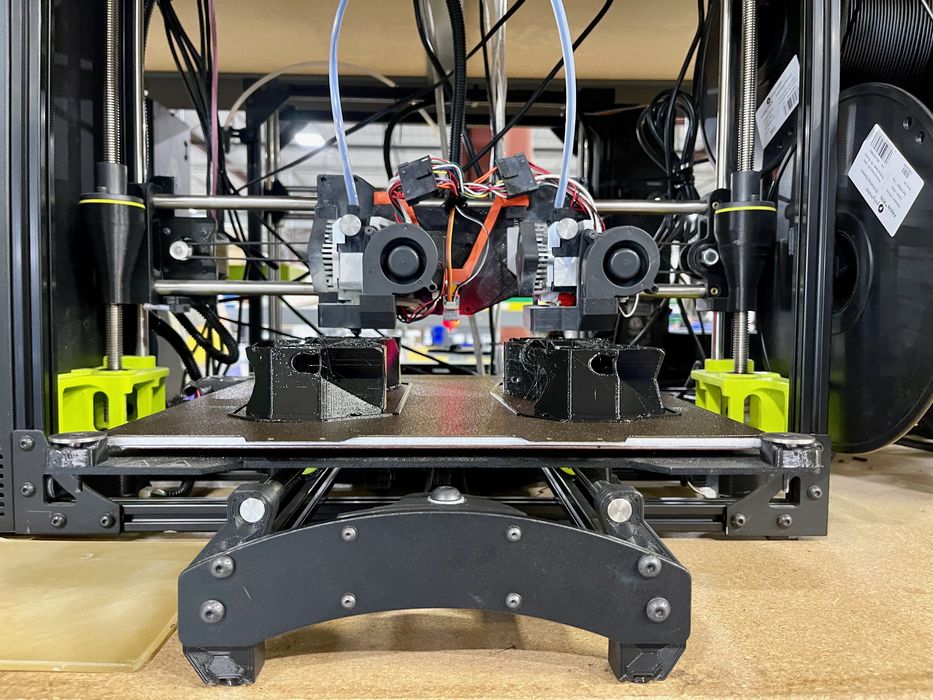

Prior to the actual 3D printer production lines, FAME 3D has a 300 unit printer farm producing many parts for all their products. This farm guarantees supply of parts for the factory, and also reduces part cost. They’re also easily able to quickly change farm production to include new designs and alter production rates.

The farm machines are not uniform: there are several different models present, and groups of machines are set up to produce parts in different materials. Most, however, have large-sized spools to reduce operator intervention.

Here we see some machines closed off because they’re producing ABS parts. The enclosure helps keep the ambient temperature a bit higher and increases print reliability.

FAME 3D has done some very cool mods to their farm to increase productivity. This is a standard single extruder device that’s been modified to have two printheads. These actually print simultaneously, so they’ve effectively doubled the production on this device with a simple modification.

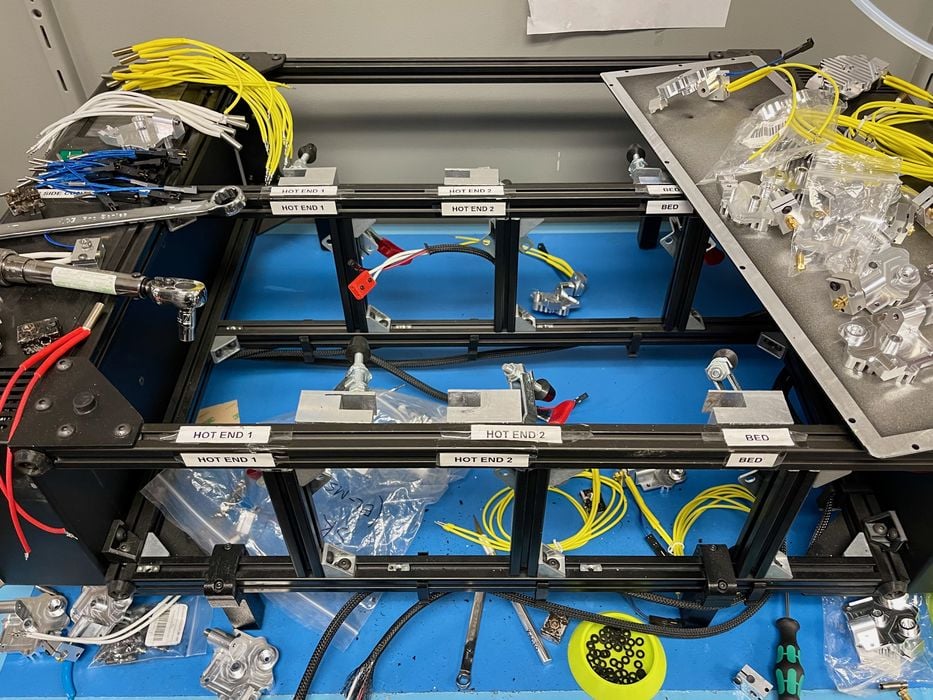

The company is highly focused on engineering, and you see examples of it everywhere. This is a specially made rig to enable thermal testing of multiple hot ends. It’s one of many simple, yet effective ways we observed that increase throughput at the factory.

The printer farm is managed from a central control console, and it looks like they use a version of OctoFarm as the management software.

Currently, FAME 3D operates four separate production lines to produce the various models of LulzBot. As is typical in 3D printer factories, the process begins with frame assembly, and the piece continues through several stages until it arrives at the calibration and testing stage.

Finally, the printers are packaged up for shipping.

But that’s not quite the end of the story. FAME 3D also maintains an extensive array of spare parts for current and prior equipment, should someone require something. They even have Insert Repair Kits, as seen here.

The LulzBot factory is an impressive setup, and FAME 3D clearly has a ton of room for expansion.

Via LulzBot