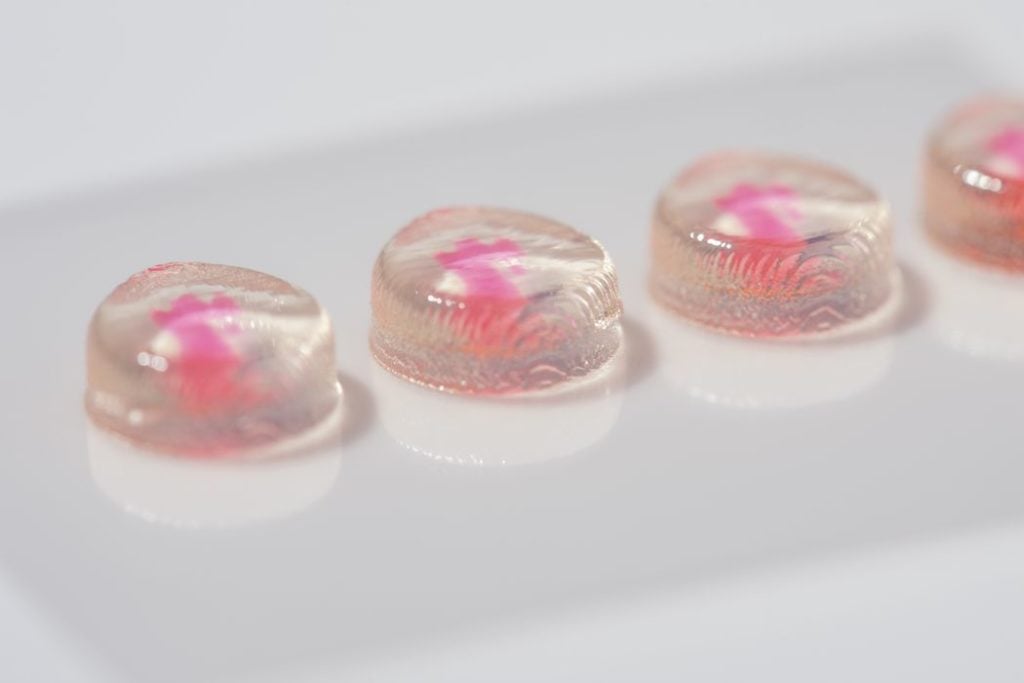

Researchers at the University of Nottingham have developed an unusual approach for 3D printing medicine.

You might be wondering what is meant by “3D printed medicine”, particularly when you see the result: a pile of pills that appear no different than any you might encounter at a drug store.

But they’re quite different, and that difference is found inside.

Pills made using conventional processes are rather simplistic in design: the chemicals are mixed in large industrial systems into a uniform powder. Then that powder is pressed into pill form. Occasionally an exterior coating is applied, but otherwise that’s about it: a mono-material pill.

3D printed pills can be far more sophisticated because the internal structure of the pill can be fully controlled. Instead of creating complex visible geometries, pill printing involves creating complex interior geometries.

These geometries can provide some very interesting functions. For example, a layer could be designed to dissolve over a fixed period of time, and when it is gone another drug can be released into the body. This allows the creation of timed release of medicine — within a pill!

It can get far more complex. Imagine a medicine regime that requires doses of chemical A every four hours for one day, followed by a dose of chemical B? That could easily be constructed in pill form by the strategic application of dissolvable layers to surround A and B chemical layers.

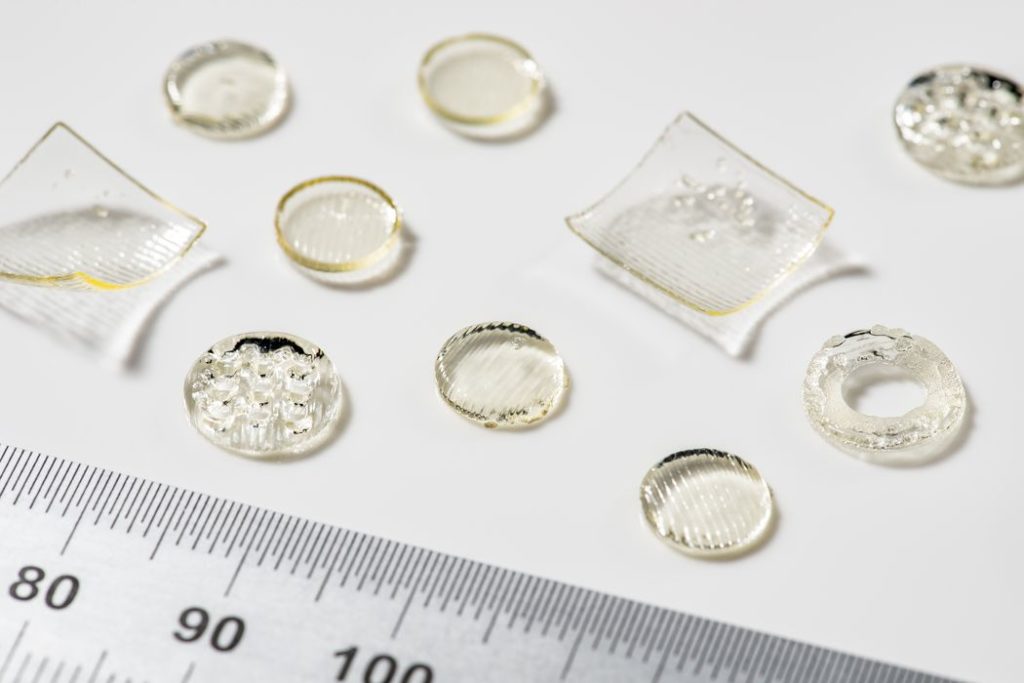

Up to now most 3D printed pill systems involved multi-material powders that would be layered together as described. However, the new system developed at the University of Nottingham could provide even more flexibility in design.

Their system involves not just powder, but in fact three different 3D printing processes. They explain:

”To make the technological leap, the team had to modify the printers to print multiple materials at the same time and employ three different types of 3D printing to perfect the technique: ink jet; stereolithography, which uses a computer-controlled moving laser beam, pre-programmed using CAM/CAD software; and extrusion printing which uses spools of plastic or metal filament that is forced through a heated nozzle, layer by layer, to create a 3D part.”

Yes, they’re using FFF, SLA and inkjet deposition processes. This provides an ability to use many more types of medicines and processes in 3D printed pills.

Team member Dr. Laura Ruiz Cantu explained the capabilities:

“We have now proved that you can print pills with many types of drugs in them and release those medicines both quickly and over time. We can tailor those tablets to each individual and their specific health needs. We can design precise doses for individuals by introducing different geometries. We can also print a bespoke pill comprising layer upon layer of sections that each contain a different drug that release sequentially as required. 3D-printed pills can be manufactured wherever and whenever they are needed which reduces shipping costs and times. This revolution in the supply chain will not only save lives, by helping people in developing countries to afford better medication and reach patients in remote or challenging areas such as conflict zones, it will also cut transport emissions, making a positive impact on climate change.”

While this technology appears enormously powerful, it will likely take many years for it to cascade down to individual doctors who eventually could order precision medical regimes for their patients in pill form. There’s also the matter of regulatory approvals.

That could be the future, but for the moment you can gain a greater understanding of 3D printed medicine by using the team’s online “Polyfill Pharmacy” game, where you can simulate the design process for these advanced pills. You’re presented with a patient having specific needs, and you follow through with simple design orders.

It’s fun, but I’m afraid I killed my first patient. Perhaps you can do better.