Wait, a removable plate for resin 3D printers?

The evolution of 3D print adhesion has gone through many stages, but in the FFF space there’s been a convergence on a single style of solution: the removable magnetic spring steel plate.

These plates, coated with PEI or similar, have become a standard for FFF equipment. Prints produced on them are very easily removed by simply picking up the plate and twisting it. Prints would pop off because they don’t bend, while the plate does.

But let’s move over to resin 3D printing, where the typical setup involves sticking a print to the bottom of a rigid metal print plate, which slowly rises as the print proceeds. Once complete, the operator must remove the print by force.

“By Force” usually means wielding a sharp scraping device, and wedging it under a corner of the print. By carefully moving around one can eventually pop off the print, hopefully without too much resin mess flying around the work area.

To ensure the print sticks many use print parameters that overly expose the first layer making it stick incredibly well. This means it can be very difficult — and dangerous — to remove resin prints. It’s very easy to slip and have the sharp scraper slice into your skin, nitrile gloves or not.

Operators have tried to minimize this problem by using special rafts that include an overhang for easy grabbing by the scraper, but even so, it’s just not the best way to do it.

Now there could be a new approach that could overcome these resin printing issues. Italy-based Morena Scarpa has designed a magnetically attached spring steel plate for resin 3D printers.

The idea is much the same as in FFF 3D printers: the print is more rigid than the flexible plate, and a twist can pop it off without issue.

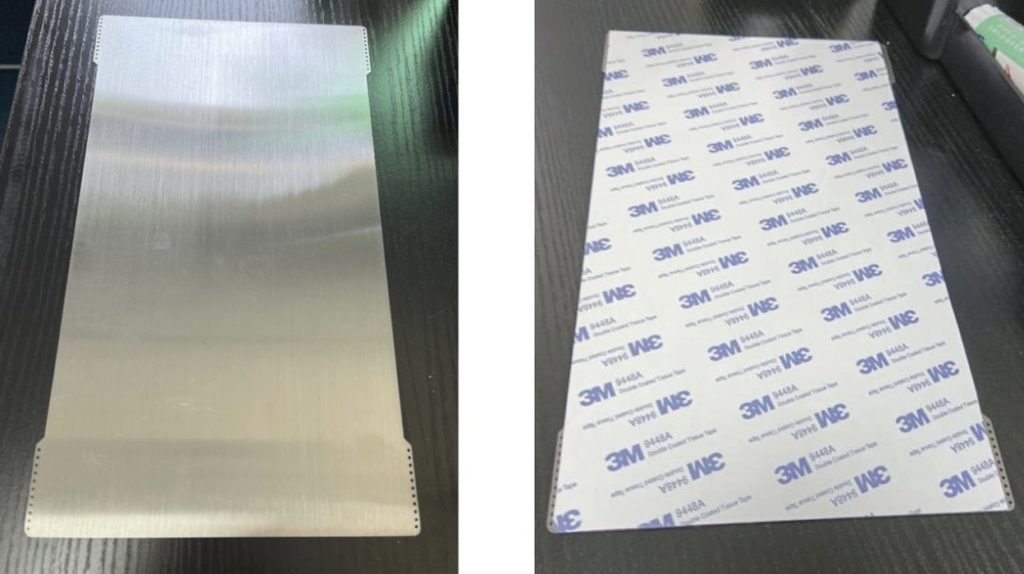

But how do you attach a spring steel plate to the (usually) aluminum print platforms on desktop 3D printers? That’s where the design is interesting.

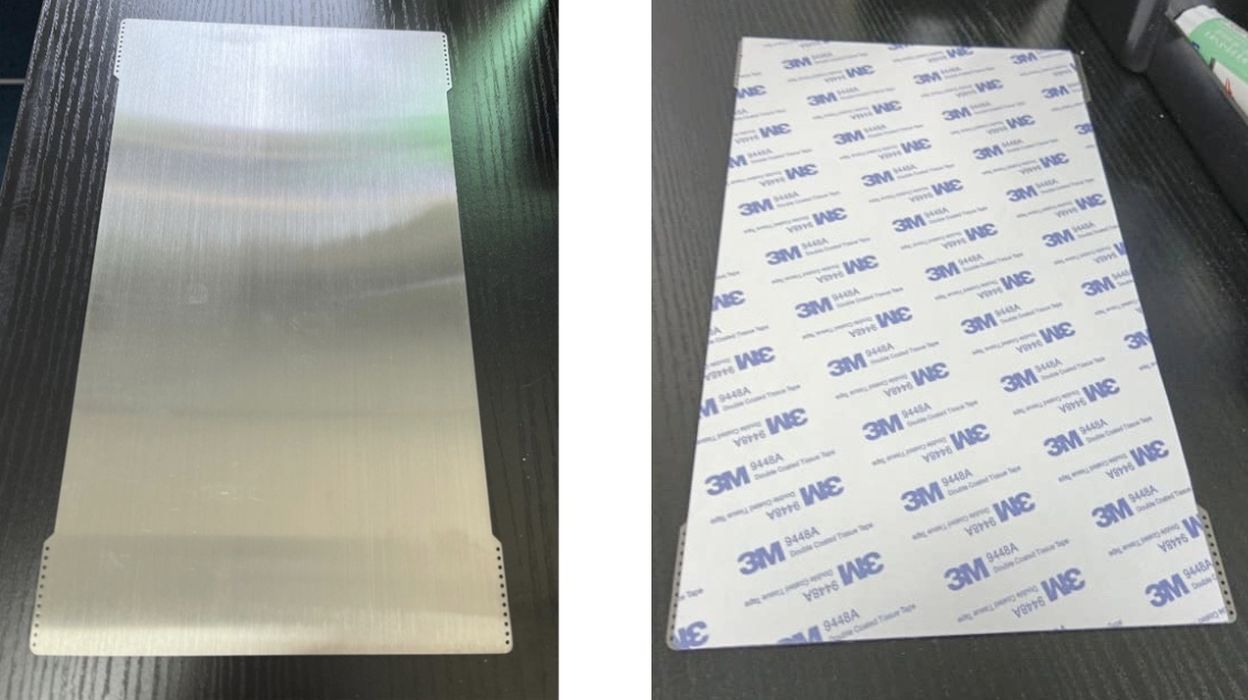

Moreno has included a sticky layer that is applied to the original print platform, which is magnetic. The steel plate then attaches magnetically to the platform.

Printing on the new plate naturally requires a re-calibration of the printer, because the spring steel plate adds a bit more distance.

Moreno explains his motivation behind the project:

“On Kickstarter I supported the Elegoo campaign for the foundation of the Jupiter 6K and immediately after I looked for a flexible plate that could give me the possibility to remove the print from the plate without having to disassemble the entire upper base every time but, looking on web, I came across in really exorbitant costs.

Also in this case, I did not beat myself up and I decided to produce the flexible plate with my own strength and, knowing that I am not the only one in these conditions, I decided to share this choice with as many people as possible: make it accessible to everyone, with honest prices without sacrificing safety and quality, of course!”

And regarding the plate’s design:

“The Flexi Build Plate is made from high-quality spring steel that won’t kink or warp when you flex it, it just return to shape! The Stainless Steel has been formulated with a Chromium Alloy creating rustproof steel for long life even if scratched. They have a custom super etched textured finish on both sides for an amazing grip and most important 4 edges in the corners for a perfect control of the prints and perforated to prevent resin build-up!”

At this time, the initial Flexi Build Plate is available only for the Elegoo Jupiter 6K 3D printer, but I imagine that if this campaign is successful, Moreno might consider producing plates sized for other machine models.

You can pre-order a unit composed of a magnetic base and the plate itself on Kickstarter for only €43 (US$47), which is 40% off the eventual retail price.

Via Kickstarter

Some rando running a kickstarter which may or may not SOMEDAY eventually fulfill its pledges

OR

WhamBam, a company which has made magnetic flexplates for MOST resin printers, including the jupiter, for quite awhile now, that WILL DELIVER in a few days time….and theyll even add new sizes if you picked up a printer they dont have a FBS for already