Resin 3D printers produce amazing output, but why do they have to be so messy?

While most desktop 3D printer setups use filament-based 3D printers, there are an increasing number of resin-based alternatives that are making their way into workshops around the world.

This is due to two factors: resin 3D printers typically produce far better output, as the resolution is greater; and the costs of such equipment have dramatically dropped, now about the same price as filament-based equipment.

Resin Toxicity

With an increasing number of people using resin equipment, the flaws in their design are becoming more well known. In particular the toxicity of the resin is far too often treated too lightly by operators.

Most photopolymer resins are actually quite toxic until they are solidified during light exposure. In their liquid form they can be absorbed by the skin, and thus enter the body. Normally nothing much happens until a critical amount is absorbed, and then the body provokes nasty reactions, and sometimes individuals become incredibly sensitive to resin exposure.

It’s advised to wear PPE when operating these devices, and that includes nitrile gloves, sleeves, safety glasses, etc. These hopefully will prevent directly exposure to the harmful liquid resins.

3D Printer Resin Mess

However, avoiding exposure is made far more complex by the design of many resin 3D printers. They are, in almost all cases, incredibly messy devices. It’s nearly impossible to avoid sloshing resin on top of surfaces near the device unless you are extremely careful.

Quite a few resin 3D printer setups will eventually be coated with resin. It will be on the sides of the machine. It will be on the table the machine sits on. It will be on the tools used with the machine. It will be on the machine’s control panel and buttons.

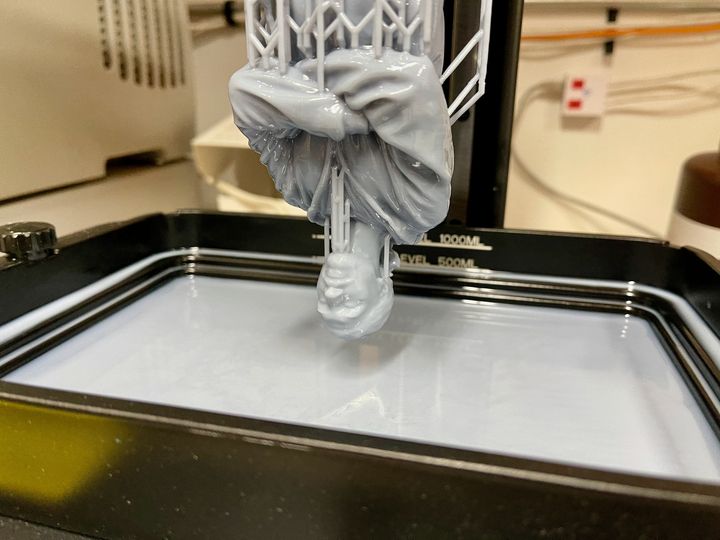

Here’s a typical example of a common machine design that almost always results in a spill. Normally a completed 3D print is left hanging upside down in the build chamber. It’s still wet with liquid resin that was adjacent to the solid portions in the tank during printing.

After the print completed, much of this liquid resin will naturally drip off into the tank below. That’s good, but there are almost always surfaces that capture liquid resin in a way that prevents dripping down. This could be a flat surface, or some geometry of the print.

In most cases, this includes the build platform itself, which is repeatedly submerged in the liquid resin during printing.

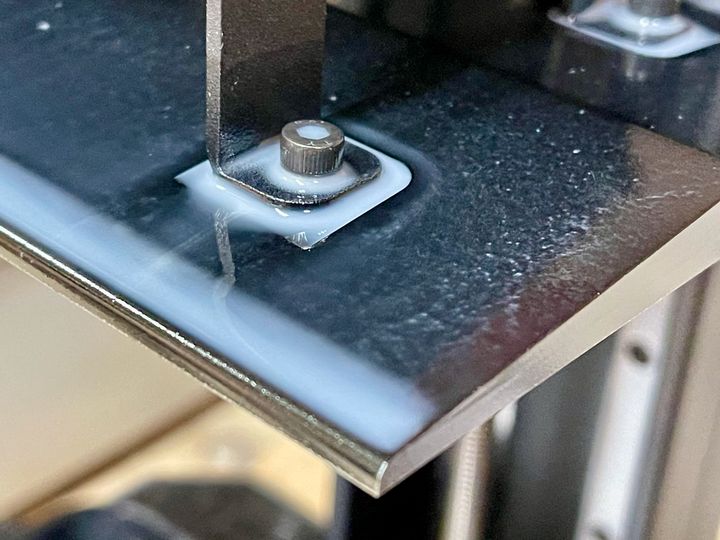

The problem is that when the platform is detached for post-processing, it is invariably tipped, and this allows new drips to form and fall where they may. They could drip on the machine, table, or even you. Personally, I try to hold the platform extremely level until I get it over to the post-processing stand, where resin is allowed to slop out.

But not everyone does this, and you end up with drips everywhere. These drips remain toxic and don’t really dry out. Over time they get smeared around and form a layer of toxic slime on many surfaces. Eventually you’ll have to clean your work area with IPA and in extreme cases use UV exposure to solidify some of the mess to render it non-toxic.

Post-processing activities involve handling a print wet with either resin or resin-infested IPA, and this ends up on gloves, tools, surfaces and other places. There’s just no way around this.

Changing resin is also problematic, in that you must very carefully remove the tank and tip/pour the unused resin back into its bottle. Surprisingly, most resin tanks are not designed for pouring and thus mess results. A few tanks these days now have a small indentation to assist pouring, but this is hardly sufficient.

Reducing Resin Mess on 3D Printers

I believe a great deal of this mess could be avoided by designing these now-inexpensive devices in a better way.

Why don’t we design build platforms to not collect resin? Could they be designed to have higher sides to keep resin from collecting? I think they could.

Could resin tanks be made with large, built-in funnel structures to allow for easy and safe resin removal? Why not?

We can buy machines to wash and cure resin prints, but what about the stage before then, when wet prints must be pried off the build platform? Could we not have a device that holds the platform securely and catches both the loosened print and wet resin at the same time?

I think there are many opportunities to improve the basics of resin 3D print operation.