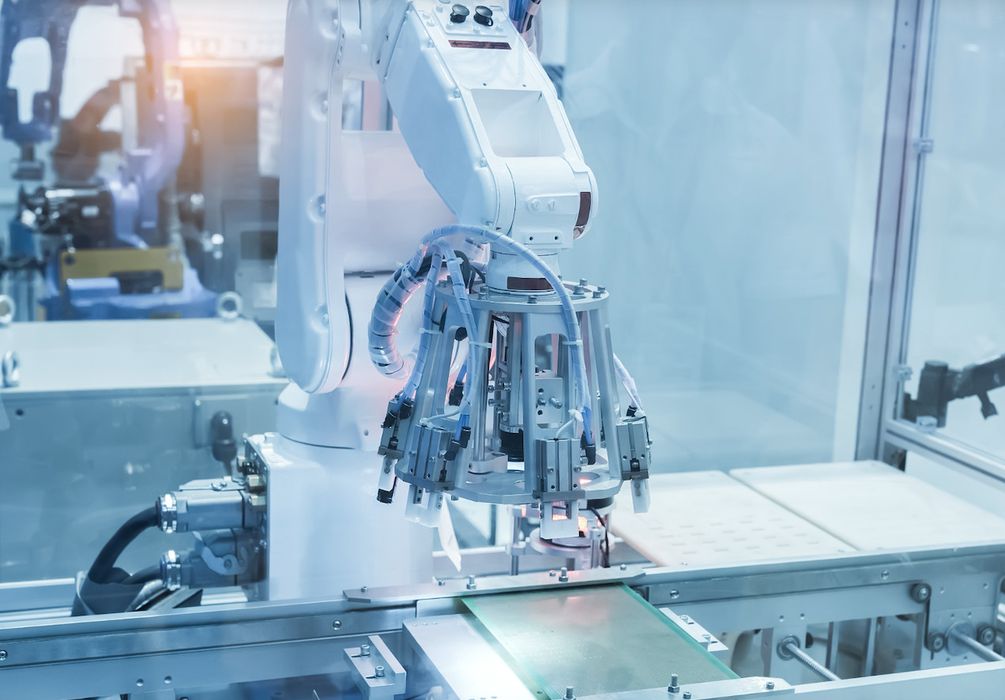

FrAMEwork developed by J.A.M.E.S is part of a growing global movement to disrupt the electronics industry.

A joint venture between German defense tech company Hensoldt and additive manufacturing technology company Nano Dimension has created a cloud-based online platform to serve a growing global 3D printing electronics community.

The joint venture called J.A.M.E.S (or Jetted Additively Manufactured Electronics Sources) launched the platform called FrAMEwork on July 5 with the goal of convening a design community involved in Additively Manufactured Electronics (AME). The AME designers hope to push the manufacturing world away from the subtractive process, which wastes material, and move it toward applying additive manufacturing to electronics resulting in a more environmentally friendly and potentially more efficient process.

The collective aims to be the leading global authority on AME and ultimately disrupt and redefine the electronics industry.

“Our mission is to provide a space where anyone across the globe can share stories and ideas about AME, exchange technical know-how and designs and enjoy the benefits of real-time communication with AME enthusiasts and professionals,” said Andreas Müller, CEO of J.A.M.E.S, in a press release. “AME enables new and visionary applications in electronics that cannot be realized with conventional electronics manufacturing, and we strive to enable members to explore new possibilities in 3D.”

AME’s potential lies in the increasing availability of innovative materials, such as functional fluids or inks. New hardware has also helped. For example, Nano Dimension’s DragonFly AME 3D printer is an inkjet-based printer that can simultaneously 3D print a dielectric ink or photopolymer, and a highly conductive silver nano ink to produce 3D-printed AME structures. This allows each voxel or 3D pixel to be either conductive or nonconductive.

The DragonFly printer has helped J.A.M.E.S gain project experience in AME design. One of the projects involved combining various electronics into a single 3D-printed drone frame. A J.A.M.E.S research team combined a variety of components into the AME drone, including a flight controller, four motor controllers and four motors in one frame. According to Müller, the drone demonstrates the possibilities of miniaturization with AME as the technology’s 3D printers can print at the micron level, reducing the size of electronic components while maintaining or even exceeding effectiveness.

“This emerging technology can only be taken to a next technical readiness level if we are able to combine different processes, materials and design methods,” said Andreas Salomon, CTO of J.A.M.E.S, in a press release. This is exactly what J.A.M.E.S is ideally suited for: empowering members of the J.A.M.E.S Community to gain experience with inkjet, micro-dispensing, ceramic printing, aerosol printing and all other processes currently on the market,” Salomon added. “Merging technologies is the future of AME with a huge potential to completely change the traditional way electronics are manufactured.”

Read the rest at ENGINEERING.com