I spoke with ActivArmor Canada’s Kyle Stanley to learn more about how Active Armor operates internationally.

ActivArmor is one of the longest operating application services that depends entirely on 3D printing technology. Their business model is to 3D scan a patient and 3D print a custom-fit cast, splint or other personal apparatus.

There’s significant advantages to 3D printed casts, as anyone who has endured a plaster cast would attest. The 3D printed versions are “sparse” with many holes and allow air to pass through. Itches can be scratched, too.

ActivArmor explains their value:

“ActivArmor is the only waterproof, breathable, sanitizable custom plastic cast in the U.S. consumer marketplace. It empowers patients with the freedom to be able to stay safe and maintain their active lifestyles.”

That’s great, but what about folks outside of the US? Can they use ActivArmor?

Not directly it turns out, because there are vast differences in how health systems operate in different countries, as the US health system is pretty unique. The steps required to integrate ActivArmor’s products into a health process vary considerably.

Because of this, ActivArmor sells only in the US. But hold on, there are ways to obtain ActivArmor products in other countries. How does that work?

I had a discussion with Kyle Stanley, who is the owner of ActivArmor Canada, which provides ActivArmor product to the Canadian marketplace. Stanley explained how his independent company relates to ActivArmor “galactic”.

Stanley said ActivArmor Canada signed a detailed contractual agreement with ActivArmor USA. The contract allows ActivArmor Canada to provide 3D printed products to the Canadian marketplace, as well as using the ActivArmor branding.

The business operates on a transactional basis: Stanley’s company acquires the 3D scan data and sends it to ActivArmor USA, where their servers and software generate the required custom 3D model. Then this new file is sent to ActivArmor Canada, who physically produce the part and distribute it to the Canadian buyer. ActivArmor Canada pays ActivArmor USA a fee for each transaction, and ActivArmor Canada’s pricing accounts for that, plus some profit.

Stanley explained that ActivArmor is active in several countries now, and each participant is making their own arrangement with the company. It is much like a franchise model, however. Stanley believes ActivArmor Canada is the first actively operating international entity.

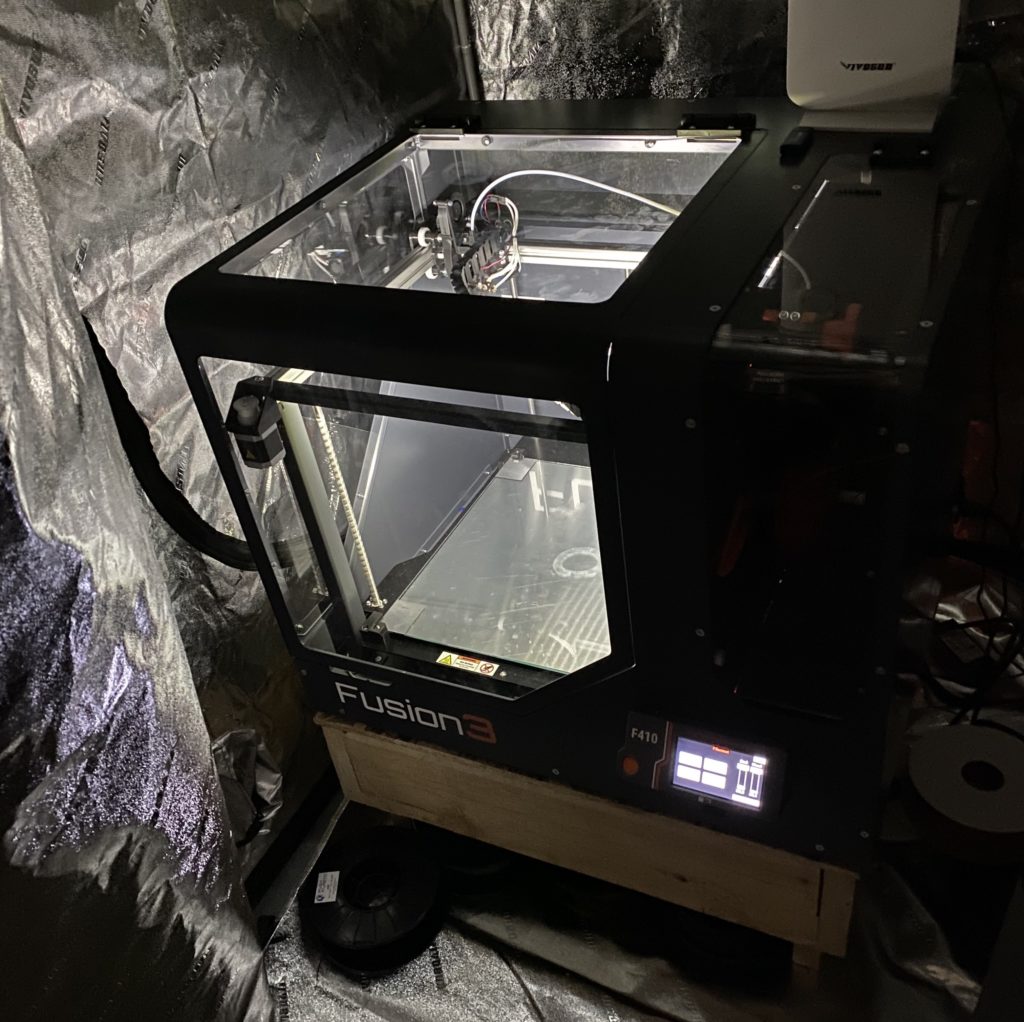

Like ActivArmor USA, ActivArmor Canada uses Fusion3 F410 3D printers for production, currently with three units. Meanwhile, the US operation has 29 at this point. Stanley explained he uses ABS filament from Push Plastics for his products at the moment.

Stanley operates the machines himself, as well as performing the required post-processing — the parts must be smooth, as they touch skin. But this may change as the business grows; they’ve only been open for a very short while and have a long way to go.

So far, this approach sounds pretty straightforward: get a scan, get the 3D model, print and ship. But in reality it is far more complex.

The challenge in this business is not the 3D printing; that’s the easy part. The hard part is integrating with the health system.

Stanley’s challenge is to make both patients and doctors aware of the ActivArmor option when receiving casts and splints. This means a significant advertising and marketing campaign is required.

In Canada, basic casts are provided at no charge under the country’s federal healthcare service. However, after 1-2 weeks elapse and swelling has abated, patients could opt for (and pay for) an ActivArmor product. Due to health regulations, the act of obtaining the ActivArmor cast must be done under the supervision of a medical professional.

In practice this means the doctors have to take the 3D scan and measurements and produce a prescription, which sounds a bit daunting. However, ActivArmor has provided a free app that can guide the physician through the process in a relatively painless way. The app can handle the basic products, but for more advanced situations it’s required that the patient be professionally 3D scanned with TechMed equipment.

Is it difficult to persuade doctors to present the ActivArmor products to patients? It turns out no, as Stanley explained he simply shows a sample cast to them and there is immediate curiosity and interest. However, there are a lot of doctors and patients to make aware of the process.

This seems to me to be a pretty decent business model: people are constantly breaking bones, and require casts. Stanley needs only to make enough people aware of the option and the sales will come through.

I asked Stanley what got him interested in this particular business, and he explained that his family business is in the medical sector, but that he also has survived no fewer than three motorcycle accidents involving broken bones.

He understands the importance of casts, and is providing a great option for others with broken bones.

Finally, anyone else with similar backgrounds in other countries might consider contacting ActivArmor USA if they wish to open up 3D printed cast services in their countries.