FluidForm’s FRESH technologies may offer a solution to 3D printing challenging materials such as collagen and silicone.

Limited organ donors, medical materials unable to support human tissue growth, and costly drug testing failures are all challenges that researchers face in the medical field. 3D printing is steadily becoming an alternative for making progress in these areas but still has its limitations, especially when it comes to engineering human tissue.

FluidForm, a Massachusetts-based regenerative medicine company, aims to take on those challenges with its liquid 3D printing technology.

Most current 3D printing methods and research rely on modifying existing materials to enable printing them in air. The downside of that method is that it often results in an unwanted physiological change in the materials.

FluidForm took a different approach while developing a technique called Freeform Reversible Embedding of Suspended Hydrogels (FRESH). Instead of changing the material, the FRESH method modifies the 3D bioprinting environment. This enables printing with collagen, silicone and proteins, as well as any liquid polymer resins—the latter of which may be a boon to other industries, such as aerospace and automotive.

Beginnings of FRESH

Much of the FRESH technology came about in the Regenerative Biomaterials and Therapeutics lab at Carnegie Mellon University (CMU) by Adam Feinberg, FluidForm CTO and cofounder, and professor of biomedical engineering and materials science. In 2018, Feinberg’s core technology to 3D print collagen resulted in the launching of FluidForm.

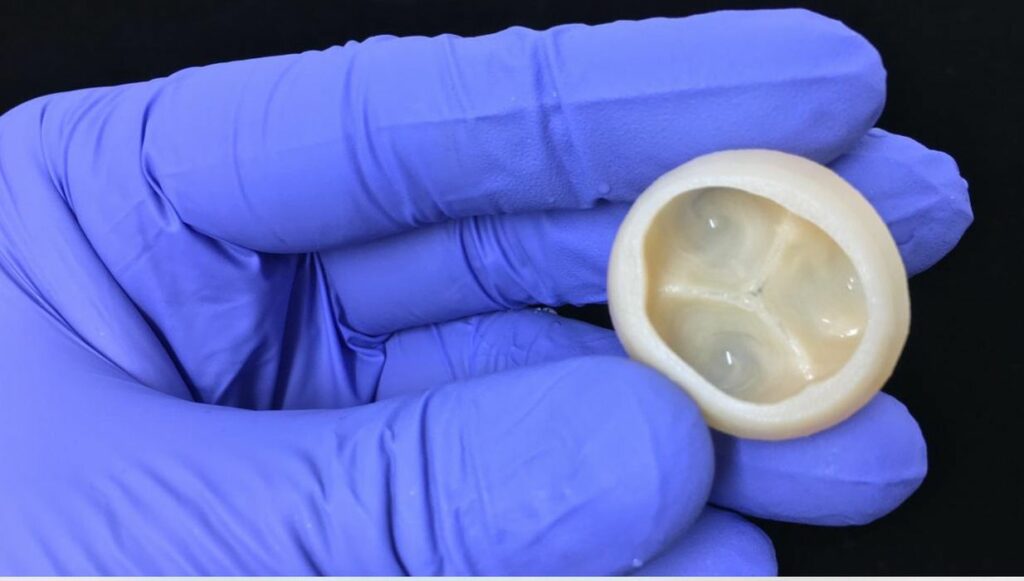

The following year, the company’s proof-of-concept study was published in Science. The team was able to accurately reproduce the anatomical structure of hearts from patients’ unique MRIs.

How FRESH Technology Works

Current bioprinting techniques require UV light and high temperatures to work. FRESH eliminates those necessities by enabling the 3D printing of cells and proteins using natural gelation chemistry—enzymatic, ionic, pH—via its LifeSupport bath. Bioinks and other materials are injected into the bath, which supports and rehydrates the materials for extrusion while ensuring that no deformation or collapse occurs. Unlike printing in air, this bath triggers chemical interactions to happen naturally. After printing, the hydrogel is melted away using heat.

LifeSupport enables different materials to be printed together into any geometry without the fidelity of the printed part being affected. Additionally, other proteins can be added to ensure the tissue properly develops. This enables the creation of a tissue structure similar to how the human body builds it.

According to FluidForm: “LifeSupport can be rehydrated in a range of buffers and cell culture media to support multiple cell types and specific bioinks. LifeSupport can also be rehydrated to support the cross-linking and/or gelation of multiple types of bioinks within the same support material.”

Scalability is another FRESH technology feature that FluidForm touts. Many existing bioprinters are only capable of printing something as big as a postage stamp. According to the company, the only limitation is culturing enough cells.

Read the rest at ENGINEERING.com