A new research project has made extensive use of 3D printing — underwater.

Most 3D printed parts are used in mechanical settings, and they must be made from materials that withstand the environmental conditions expected during deployment. Sometimes those conditions are quite easy to match, such as for tabletop or decorative use. Other times mechanical properties are primary, where the parts undergo stress and must survive. There are environments where temperature is a concern, or caustic chemical exposure, all of which demand careful selection of the materials used in the application.

Formlabs just published a study describing the use of 3D printing by NOAA’s Atlantic Oceanographic and Meteorological Laboratory (AOML).

AOML has been monitoring the oceans to observe the effects of the climate emergency, and this is quite a different environment from typical 3D printer applications.

Parts required are usually custom, because the studies undertaken by the group are unique, and that’s an ideal application for 3D printing. The parts must also survive UV exposure outside, salty ocean water, seal against water incursion, battle underwater pressures above one atmosphere in addition to the usual mechanical beatings. The salt in ocean water can also corrode metal, so traditional material options are pretty thin. There are few other 3D print applications that present such unusual environmental conditions.

This project was specifically investigating changes in coral reefs, which are particularly susceptible to water temperature changes caused by the climate emergency. To do so they have developed a series of custom-made sensors, most of which requires unique cases, jigs and other 3D printed bits.

Formlabs explains:

“To fight coral reef loss, scientists and researchers at NOAA and their partner institutions are utilizing innovative methods to survey coral in the wild, reproduce certain conditions under controlled settings in labs, and then cultivate new species of coral that can better withstand the extreme environments of today. The AOML Coral Program where Formel works, in partnership with the University of Miami’s Cooperative Institute for Marine and Atmospheric Studies (CIMAS) has turned to 3D printing to facilitate their field and lab research.”

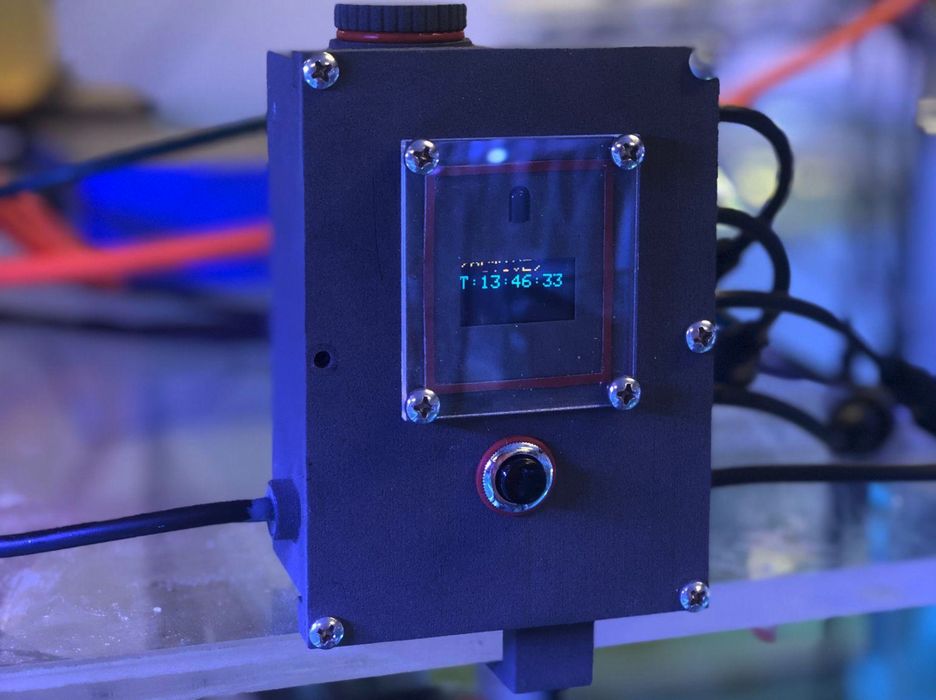

This study required the deployment of dozens of sensor units across a large area in order to carefully monitor water temperature and conditions. They must do so not only at coral reef in jeopardy, but also in high temperature locations where they can study the new cultivated species that could eventually take over depleted reefs.

More accuracy is obtained with more sensors, but collecting data from them manually is quite labor intensive, so the researchers designed a sensor device that can report on its own. They were able to use a combination of technologies from Formlabs, including both SLA and SLS, to build parts for automated sensor stations. Use of the 3D print technology allowed the research team to build quantities of the sensors at far lower cost than would be expected if they had to use conventional providers.

NOAA’s Nate Formel explained:

“We now have these very customized 3D printed components that have the necessary connection points and through-holes to allow us to collect water samples. The original sampler design that motivated all of this, we stopped making it for $1,000 and started making it for $220. That means I can now put out five samplers when I used to only be able to put out one.”

The sensors can also be used in controlled conditions. At the University of Miami NOAA researchers have set up a series of aquariums that each provide a slightly different set of oceanic conditions, which of course, are monitored by the sensors. Within these aquariums they can test different coral species survival rates.

It seems that another industry has found a very good use for 3D printing, thus enabling work to take place that otherwise might not have happened.

Via Formlabs