3D printing-and-injection molding pioneer AddiFab has introduced new capabilities at the small scale.

AddiFab Technology

Danish 3D printing pioneer AddiFab emerged last year with an intriguing technology they call Freeform Injection Molding (FIM).

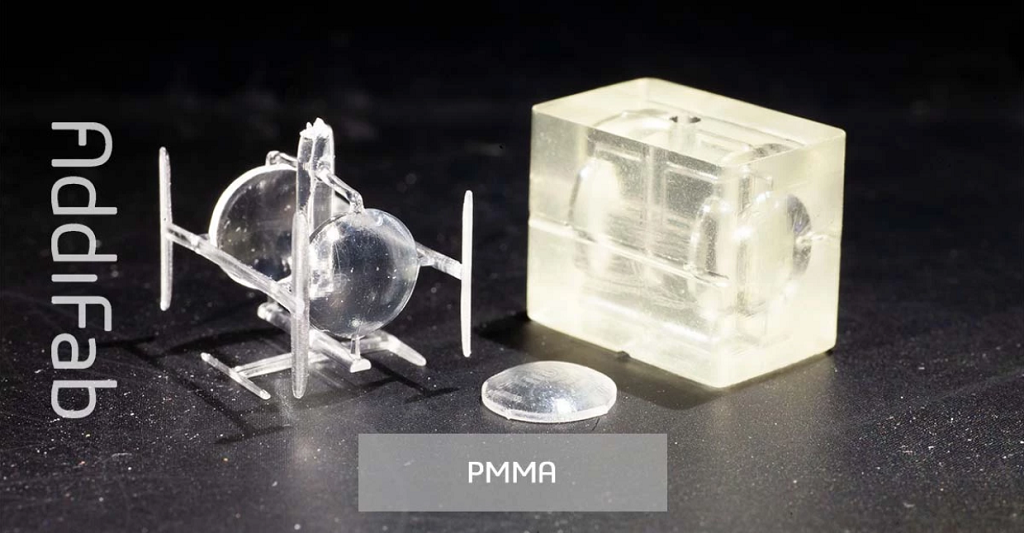

By 3D printing the molds, injection molding can gain the complexity benefits of additive manufacturing. The full process is quite intriguing, as 3D printers and injection molding systems work together to create geometrically intricate structures out of essentially any material.

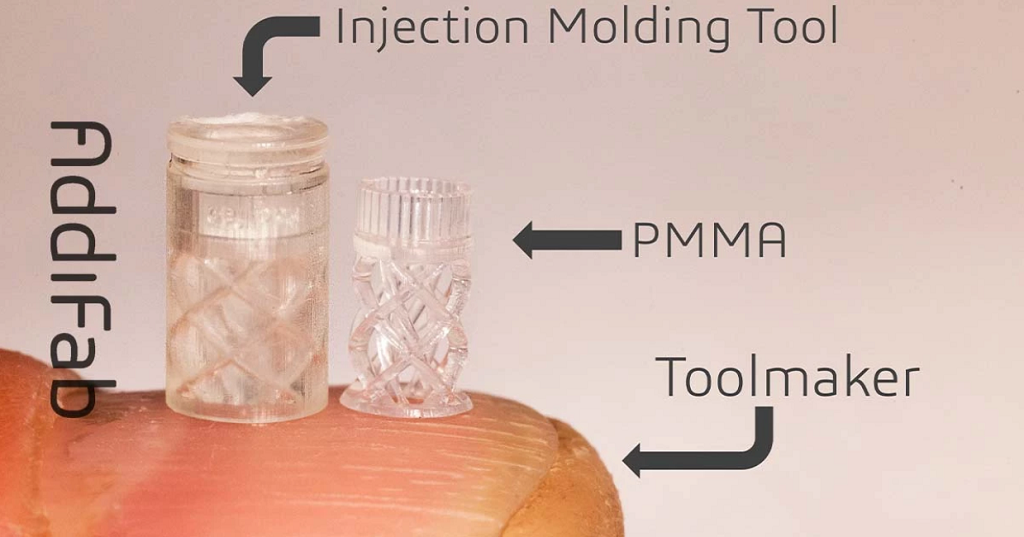

The FIM process essentially boils down to a few main steps:

- A 3D model of a desired object is created

- A negative of the 3D model is created — a mold

- The mold is 3D printed using the special AddiFab resin

- The print is then placed in an injection molding machine and hot thermoplastic is pressed into the cavities of the print

- The print/injection combo is placed in a special undescribed solution, where the print dissolves, leaving the completed injection molded part

The company lays out their goal relatively straightforwardly:

“To provide injection molders with quality injection mold tooling that has the same short lead-times, low start-up costs, and design freedom as 3D-printed parts.”

They have already shown success in using the technology to help a pandemic-targeting application scale up quickly. FIM came into play to help turn a high-performance snorkeling mask into a COVID-19-safe piece of personal protective equipment (PPE). By turning FIM to create mask adapters, the AddiFab team collaborated with a number of contributors to scale up production inside of a week.

AddLine Micro

Recently, AddiFab made another big announcement about their technology. And that big announcement is: they’re going small.

Starting off by targeting hearing aids — long a mainstay among 3D printing applications — AddiFab has introduced a new module aimed at micro injection molders. The new upgrade package is called AddLine Micro.

With the addition of the AddLine Micro, users of the AddiFab AFU5 3D printer can increase their resolution for focus on the small scale. How much does that resolution pick up?

“… from a very decent 50 µm to a top-of-the-line 10 µm. In layman terms, this means that the smallest feature achievable is smaller than a white blood cell,” AddiFab explains.

AddiFab Co-Founder and CIO Jon Jessen observes:

“AddiFab has deep roots in the hearing aids industry. From day one, it has been a key AddiFab ambition to serve this industry. With AddLine Micro — the 10 µm upgrade we are now introducing – we deliver on this ambition.”

But, the company is quick to note, the ambitions don’t stop there.

“We have also demonstrated that FIM does not impact biocompatibility in a range of rubbers and polymers, enabling device manufacturers to blitz through pre-clinical trials. Miniaturization is one of the hottest topics in the medical device industry, and we are proud to support medical device manufacturers in their efforts to bring better devices faster to market,” says AddiFab Co-Founder and CEO Lasse Staal, who has spent more than a decade developing minimally invasive medical devices.

Select beta customers will be offered the AddLine Micro package starting early in the new year. And, it seems, the interest is palpable.

“When we started reaching out to key players in the medical industry, we immediately got very strong attention,” Staal added. “Apparently, there has been a pent-up demand for solutions that allows the prototyping and low-volume production of advanced micro-components. Medical micro molders cannot compromise on materials, and with the AddLine Micro and Freeform Injection Molding we are providing the tools to ensure that they don’t have to.”

Via AddiFab