I had a quick chat with Yukun Wu, inventor of an interesting accessory for 3D printers.

Calgary-based Wu is an inventor focused on 3D printing, and he’s identified an issue that most desktop 3D printer operators encounter: idle time.

The idea here is that quite often 3D print jobs are of long duration. They’re almost always so long that the operator is not actually watching the machine, and it’s running overnight, for example. Eventually in the morning the operator shows up at the machine and finds the completed print.

The problem is that the 3D printer remains powered on for the period between job end and operator arrival. For many electronic devices this isn’t necessarily an issue, but for many 3D printers, power is consumed during this period.

Fans may continue to run (not for the hot end, but for the controller board), and the machine idles for no reason at all.

If only the machine were smart enough to power itself off after job completion. In fact, I have seen a very few machines that have this feature, but it is by no means a standard function found on most machines. Typical desktop 3D printers simply wait, slurping up power unnecessarily for hours, perhaps even days.

That’s not a good use of power. It also adds hours of waste usage on the electronic components that could contribute to early failure.

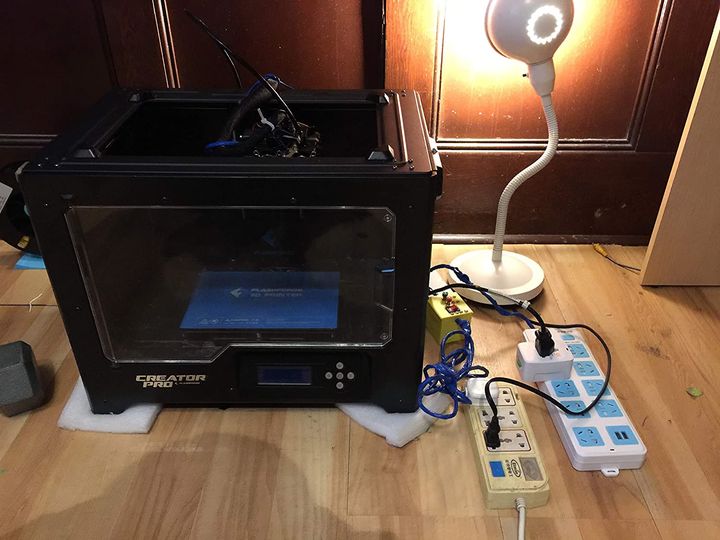

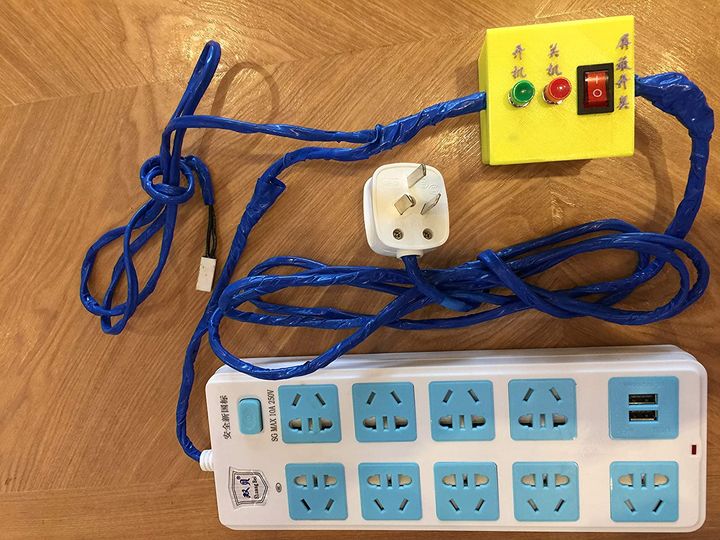

Wu has invented a device that can automatically power down a 3D printer when the job is completed, and it should work on most FFF 3D printers.

How does it work? This is an interesting question, because you might expect there to be some kind of complex communications protocol between the 3D printer and Wu’s device. The 3D printer might have to signal the device that the job has now completed and it’s okay to turn off the power.

But that’s not how Wu’s machine works at all. In fact, it’s far simpler.

Wu uses a temperature sensor that’s attached to the 3D printer’s hot end.

Normally after a 3D print job on an FFF machine, the fans continue to run on the hot end until 50C is reached. At this temperature PLA, the lowest-temperature material, stops flowing and solidifies completely. The fans run to prevent accidentally sloshing PLA into the cool zone of the hot end, causing jams.

Wu’s device, which by the way doesn’t really have a brand name yet, simply watches the temperature. When the temperature is raised above 50C, it becomes activated and then watches for a subsequent drop of temperature to below 50C. When that happens, the power is cut to the machine.

This should work well, because at that temperature most FFF devices have completed the cool-down cycle and aren’t doing much.

I can see only one problem with this device, and that is if you are doing maintenance on the machine and are heating it up and down for some reason. You wouldn’t want the power cutting out while you are doing this type of work, so I suspect you would bypass Wu’s device in that scenario. Well, it turns out that Wu has thought of this too, and includes a “Bypass” switch right on the device!

Wu is selling the device through Amazon, and has an introductory price of only CA$21 (US$16), but it seems that the price will be rising as units are sold.

It’s an interesting project that might make sense for some 3D printer operators.

Via Amazon