6K Additive announced a massive expansion of their metal powder production capacity.

The Pennsylvania-based company is known for their very unique “UniMelt” process for making “precision” metal powder for use in additive systems.

Most powder production technologies use a somewhat wasteful approach, where raw metal bits are blown into a high temperature plasma. The metal melts quickly, then cools into blobs. These are collected and then sorted by size and roundness. The most uniform particles that meet diameter thresholds are kept, and that’s how you get metal powder for AM.

The problem is that apparently the vast majority of particles produced in this process are unsuitable and have to go through the process again. Yields are not high, and that’s one of the reasons AM metal powder is so expensive.

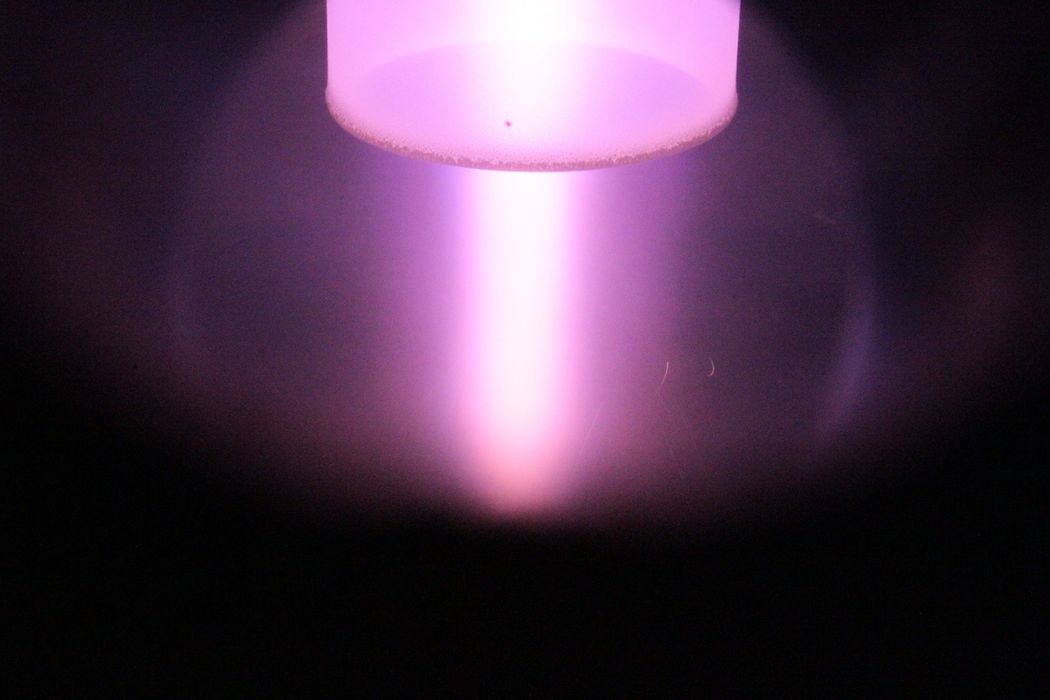

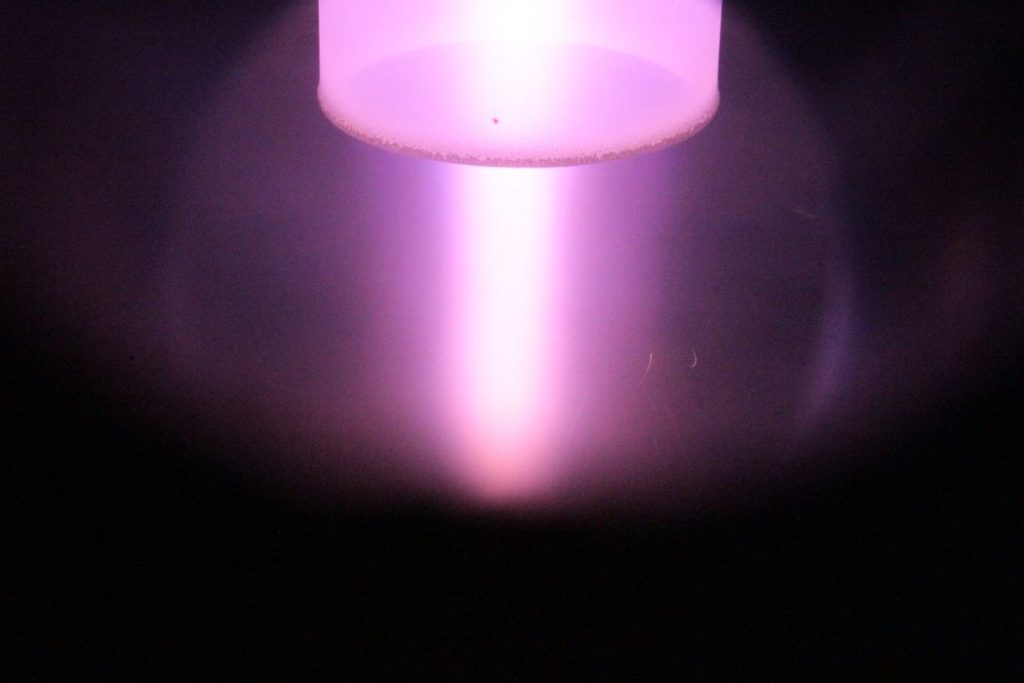

However, 6K Additive’s approach is very different. Instead of the plasma, they use a highly precise microwave system that can control the thermal environment to a much greater degree. Because of this, 6K Additive can create very high quality metal powder with far higher yields. This makes their process quite efficient and consistent.

After opening up a production line earlier this year, they’ve now announced an expansion.

The expansion consists of another 20,000sf area, which will hold four new powder production lines, and a 15,000sf feedstock preparation building. This represents a significant expansion in powder-making capacity for the company. In addition, it’s expected another 35 staff will be added to handle the increased workload.

This is understandable. The growth of metal 3D printing industry is significant, and from what I’ve learned recently, is set to grow quite a bit more in coming years as additional metal aerospace come into production status.

There’s also the quality aspect. 6K Additive’s materials are of a higher consistency in diameter and roundness than many competitors, which certainly will draw customers.

However, there’s one more reason for setting up the new plant that is unexpected.

6K Additive President Frank Roberts explained:

“Global unrest has shed a major spotlight on our nations supply chain vulnerability for critical materials. This, in combination with our consistent product quality, sustainability benefits, and the fact that we are a domestic supplier have contributed to increased commercial activity with key strategic customers. This expansion will help us meet customer demands in the coming years and ensure efficiencies in current and future operations.”

This is quite interesting. Indeed, there are several overseas (from the US) producers of metal materials, so the notion of de-risking supply chains for metal powder could be a notable factor. With events occurring in Ukraine, it’s very clear to everyone the importance of supply chains.

Does 6K Additive know something we don’t?

On the other hand, there are North American-based sources for metal feedstock, particularly in Canada. The question is really how much of that material can be made into usable powder over th next few years.

Via 6K Additive