Researchers have developed an effective way to 3D print shape memory objects.

Shape memory objects are what some would term “4D printing”. The idea is that objects can take different forms once they are produced. There will be a trigger to make this change, and typically it’s the application of heat or energy.

There are plenty of such objects in use today, but almost all are produced using conventional techniques instead of 3D printing. One of the many reasons for that is the expense of making specialized resins.

Here the researchers have found a way to produce a shape memory resin that is relatively inexpensive to produce.

How is it done? They produce the resin by mixing in liquid crystals, which are the element that activates during triggering.

The mixing of five percent weight of liquid crystals is done in a vat of resin and toluene at a specific temperature, 70C. After the ingredients are sufficiently mixed, the resulting resin is set overnight to allow the toluene to evaporate, leaving a mixture of pure resin and liquid crystals.

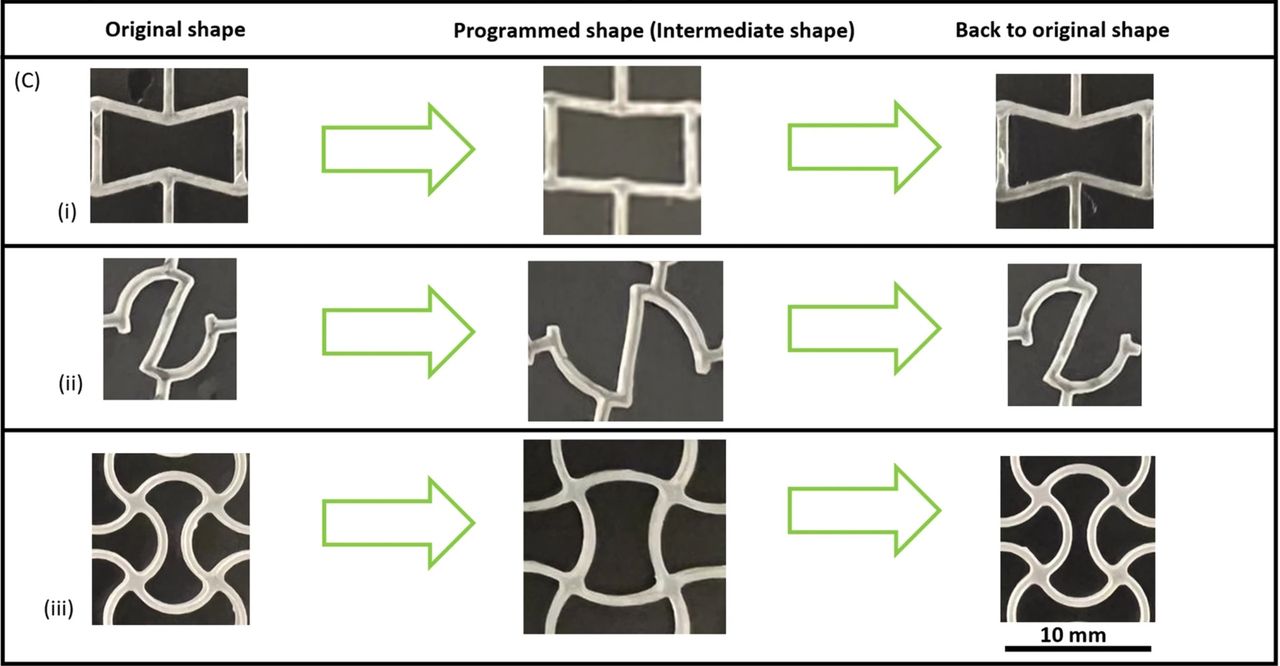

The shape memory resin does work: the researchers attempted 3D printing a wide variety of lattices and “smart” structures using a DLP resin 3D printer and observed the motion effects when heated.

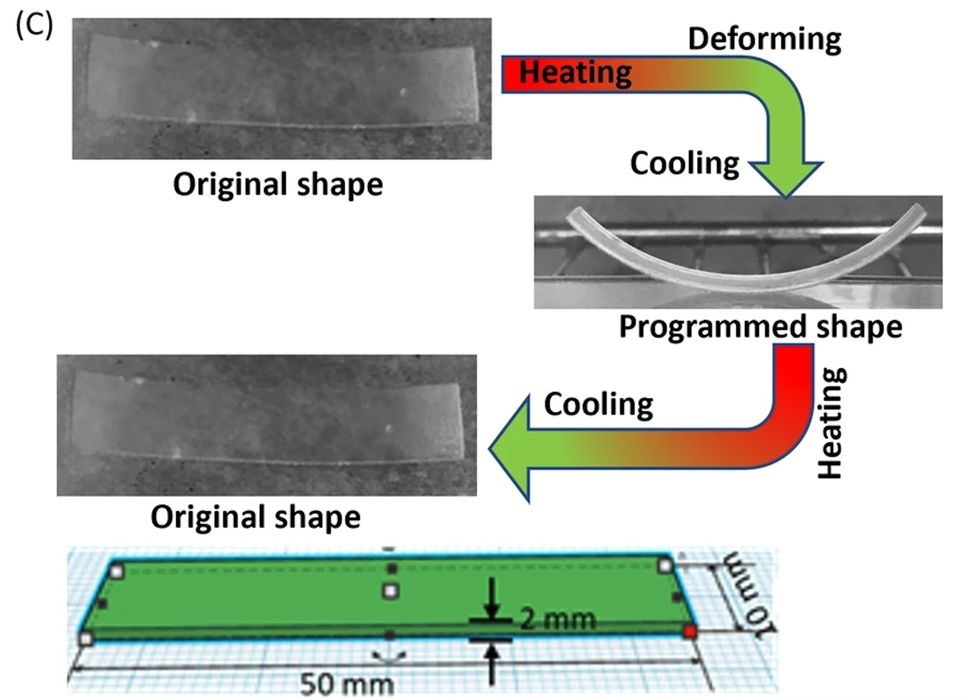

Amazingly, these 3D printed structures predictably distort when heated, and then when cooled, they revert to their original geometry. The researchers tested this effect in hundreds of cycles.

Their experiment collected quite an amount of data regarding the specifics of this motion, and that should be enough to allow predictable designs to be created. They developed ways to mathematically predict the shape distortion, which I presume could eventually be incorporated directly into a CAD system. That would allow for easy design of such objects.

These shape-changing structures can be used in a variety of applications. An obvious one would be as a temperature sensor: when heat is applied, the structure bends and engages an electrical contact. But things can get far more complex with appropriate designs.

One interesting part of the experiment was to use a shape memory lattice as a strain sensor. The researchers painted a conductive layer on top of a lattice and it acted as an electrode. They were able to measure the changes in resistance, which corresponds to the compression or expansion of joints.

I’m hoping this development will be further refined and then put into the hands of industry. This will require commercial production of “4D Resin”, as well as modifications or extensions to CAD tools to help design these unusual objects.

Via Nature