French startup 4D Pioneers offers two interesting hybrid 3D printers that have unusual capabilities.

The company was founded only a few years ago, and was apparently a spin off from a research lab. They’ve just released their second machine.

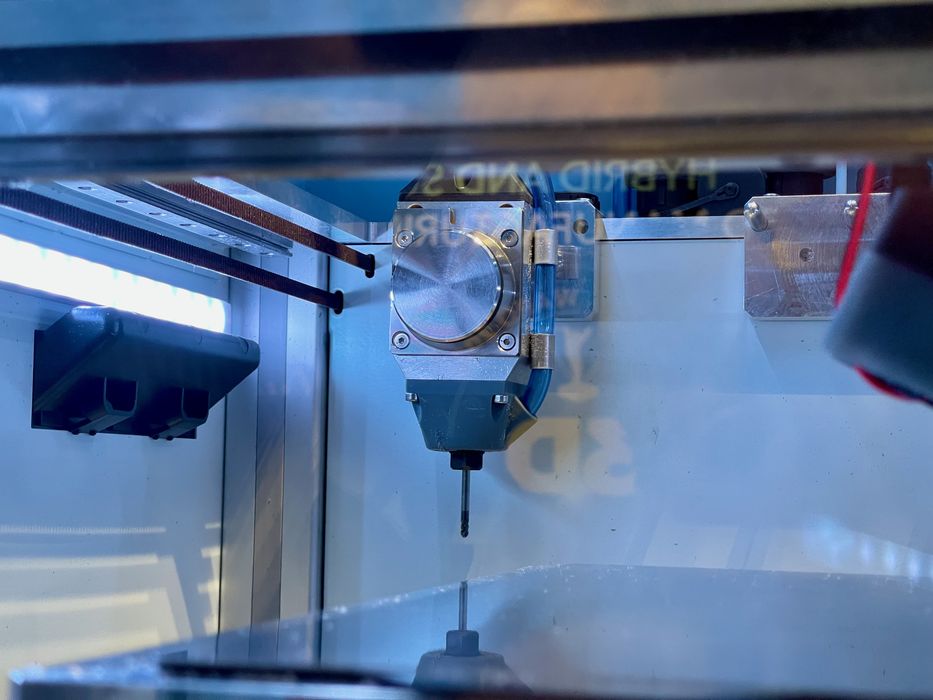

Hybrid 3D printers are normally small desktop affairs in which the 3D printing toolhead is joined with a CNC milling head to provide both additive and subtractive functionality in the same box. The concept isn’t new, but here it’s been implemented on quite a different scale for a different market.

Why make a hybrid machine? The presence of the milling head means that parts can be milled during the print job. That ensures near-perfect surface quality in addition to exact dimensional tolerances. It’s like having the best of both additive and subtractive functions in the same machine.

Their 4Prime machine, shown at top, is an industrial machine, if you hadn’t noticed the emergency stop button on the right side.

It offers a generous 300 x 300 x 300 mm build volume, and a milling head with a 3-axis motion system. There can be more than one print head, making the system multi-material as well.

The machine can be configured to use either filament or pellets, which can be far less expensive, particularly for production purposes.

The machine is self-calibrating, which is very important for hybrid machines with multiple toolheads working on a part. No operator intervention is required to change tools, and jobs run smoothly from start to finish.

The interesting aspect is that the 4Prime is a high temperature 3D printer: the nozzle can reach a scorching 500C, the print surface can hit 150C and the enclosure is heated to 70C.

This combination should allow the 4Prime to print (and mill) quite a variety of engineering materials. Combined with the milling function, the 4Prime should be able to produce ready-to-use parts right out of the machine: they will have the correct geometry and correct materials. 4D Pioneers said they can process more than 60 different materials.

The 4Prime is listed at €57,000.

If the 4Prime isn’t big enough for your application, then they also offer their latest machine, the 4Shift.

The 4Shift has a bigger print volume at 485 x 485 x 500 mm, and has improved thermals: the print surface can hit 200C, and the chamber is heated to 150C.

In addition, the 4Shift’s milling system is a true 5-axis system, making it possible to handle far more complex geometries.

We were told the company has clients in the rail, aerospace and defense industries, with considerable interest in using the systems for digital inventory applications. This involves having a library of digital parts that are printed on demand, rather than mass manufacturing them in advance and storing them in expensive warehouses. It sounds like they are testing this concept in house right now as a proof of feasibility, with intentions of moving to customer locations afterwards.

Digital inventory should be a prime application for this type of equipment. Any 3D printer capable of producing true ready for use parts would certainly be appropriate for a parts-on-demand service.

Via 4D Pioneers