3DQue announced a new service, AutoPrint3D, which provides the software necessary to drive continuous 3D printing.

Continuous 3D printing is a long-sought goal: most 3D printers are designed for single print jobs only: an operator must intervene before and after each print job to ensure the bed is clear and there is sufficient material to proceed.

But what if you didn’t have to do that? What if a 3D printer could run “continuously” and produce volumes of parts with little or no human intervention? That’s what 3DQue is all about.

The Vancouver-based company’s first products involved a hardware change to the print surface that predictably releases completed prints. By placing the printer at an angle, this allows gravity to remove the print jobs easily for collection. This clears the way (literally) for the next job in the queue to be dispatched, and that’s continuous 3D printing.

But hold on a moment. A “queue”? Most desktop 3D printers don’t have a queue of jobs. They just have an SD card with a pile of files that must be individually launched when the machine is available.

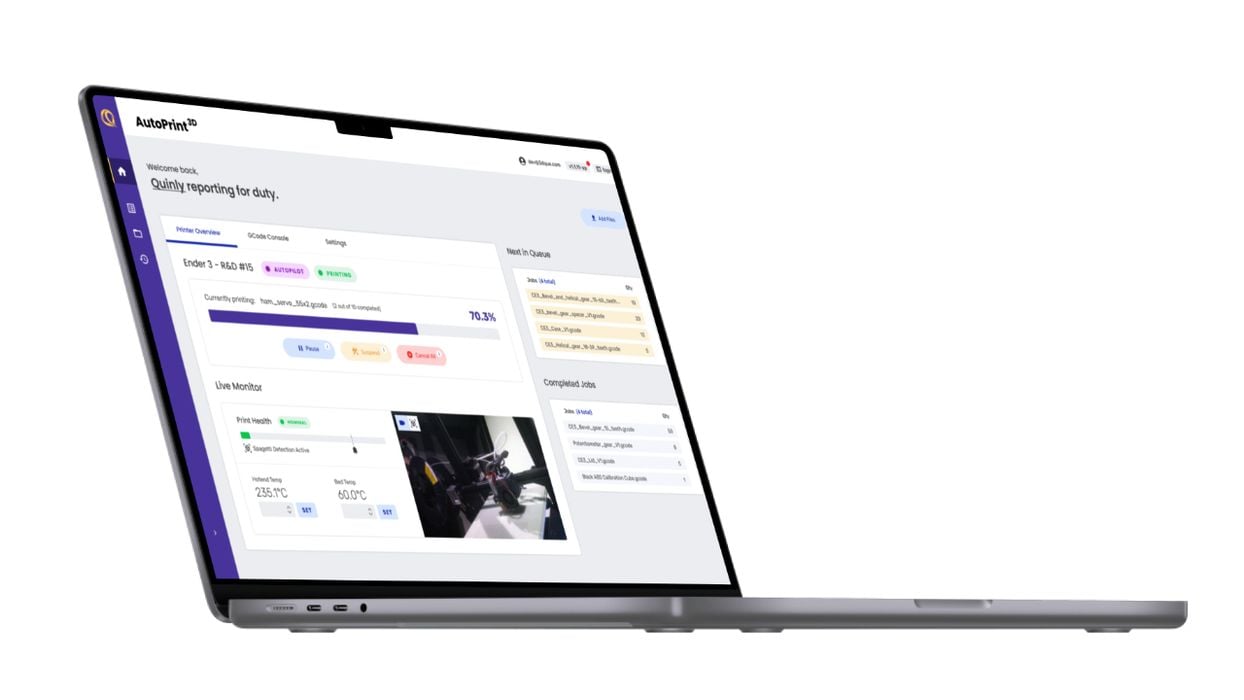

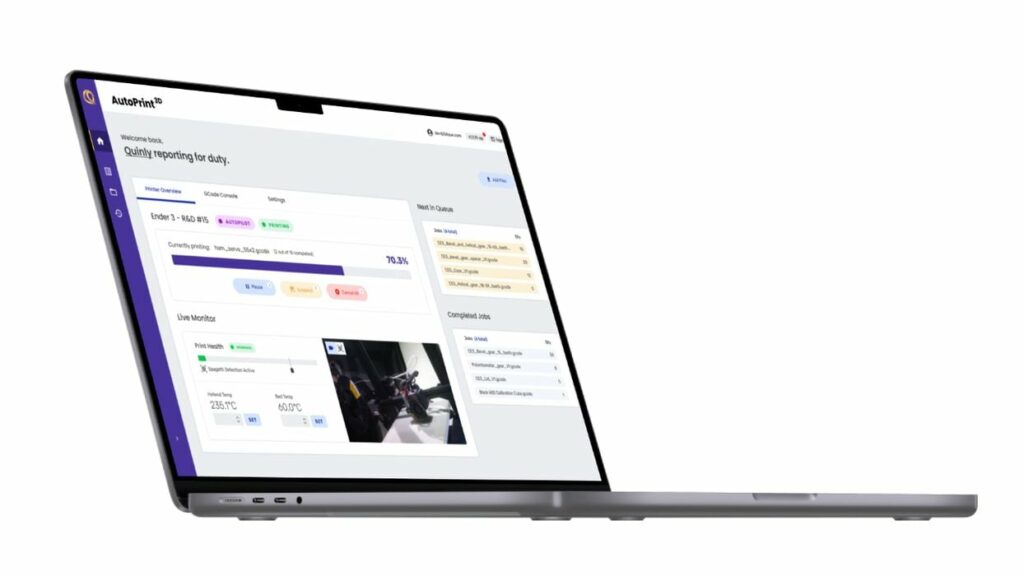

You actually need some sophisticated software to hold the jobs and be ready to automatically dispatch a new job when the prior job completes and is removed. That’s a key part of 3DQue’s automation system, and that’s essentially what they’re offering with the new AutoPrint3D service.

The software implements a job queue for printers, and handles the dispatching, as well as a number of other useful operational features. While originally designed for 3DQue’s VAAPR print surface solution, AutoPrint3D works with almost any 3D printer with Marlin firmware. Of course, it’s most useful with devices that are physically capable of removing completed prints, like belt 3D printers, or the company’s own VAAPR system.

There are actually three different levels of the system: ClickPrint3D, AutoPrint3D and AutoFarm3D, each with an increasing number of features (and pricing).

The most basic level is ClickPrint3D, which is available for US$5 per month, per printer. This level provides the ability to infinitely queue jobs and files for a single 3D printer, as well as monitor, record and control the jobs when active. Files can be uploaded, managed and sliced for printing using various popular slicing programs.

ClickPrint3D users will be able to perform order management functions for customer requests. It also includes access to 3DQue’s AI-powered SpaghettiVision system that automatically detects various types of print failures, and alerts the operator. Finally, this level also includes a unique FireVision AI-powered feature that similarly watches for smoke and fire events.

The AutoPrint3D level, available at US$10 per month, per printer provides all those features, and adds the ability to monitor two 3D printers via dashboard, and handles automated removal capabilities. There are also advanced video and imaging features, and advanced a number of features related to Prusa MK3S+ equipment, including crash detection, self-testing, automated Z alignment and more.

Finally, the ultimate level is AutoFarm3D, which is targeted at low volume manufacturers, priced at US$30 per month, per printer. This level provides all of the above and adds features like Shopify & Etsy integration, product tagging and automated queuing from incoming requests. The AutoFarm3D service provides comprehensive methods for managing large farms of 3D printers, including the ability to perform mass firmware updates, tracking of filament usage, maintenance schedules, inventory management, 3D farm layout views, and much, much more. You’d best take a look at 3DQue’s extensive list of features here.

To see how powerful this is, please watch this short video and imagine you have a small farm of 3D printers with the ability to automatically remove prints:

I particularly liked where the number of parts is increased to “20” at the click of a button, and shortly after you’d see those 20 parts be completed. This is quite powerful.

As far as I can see, AutoFarm3D offers essentially everything you’d need to create a low volume manufacturing pipeline from online store to shipping parts — except for the printers and filament, of course.

There are a few other solutions on the market, but none seem to be as comprehensive and “end-to-end” as these from 3DQue.

This service should be of considerable interest to the growing number of low volume manufacturers that now manually operate small farms of 3D printers — whether they have automated print removal or not.

Via 3DQue