3DQue announced their flagship software product, AutoFarm3D.

The new software is intended to help manage farms of 3D printers operating in parallel, with capacities for basically an unlimited number of participating 3D printers, or at least a thousand, according to 3DQue.

The company has been working on this software for three years, culminating in the recent release of the software.

This software solves a problem not everyone has, as AutoFarm3D is targeted at those using an array of 3D printers for low volume production applications.

It’s an insidious problem: a maker discovers they can print and sell an item profitably. Then they scale up by adding another 3D printer to get more throughput. And then more 3D printers. And more.

Eventually the operator finds themselves running around the workshop tending to machines constantly, starting, stopping, cleaning beds, loading material, etc. It rapidly becomes a huge amount of labor. Often assistants are hired to simply run machines, and that’s expensive, unpredictable and error-prone.

This scenario might not be one you encounter personally, but there are an increasing number of small manufacturers that do have this exact issue.

3DQue’s key invention was the VAAPR print surface, which is essentially a controllable bed that can predictably release a print once complete. By tilting the machine it’s possible to automate printing by having the machine remove its own prints automatically.

That concept works wonderfully for a single machine, but things get more complicated when an array of ten or a hundred machines is involved. I’ve personally seen large print farms, and most of the time there has been custom software written to manage them. Unfortunately, the typical Etsy maker scaling up doesn’t necessarily have the resources or skills to build that software.

That’s where 3DQue’s AutoFarm3D comes it. It’s a software package that can perform much of the labor intensive work, particularly if combined with the VAAPR system.

What does AutoFarm3D do? Here’s list of the functions:

- SmartTags farm organization system to match jobs with compatible printers

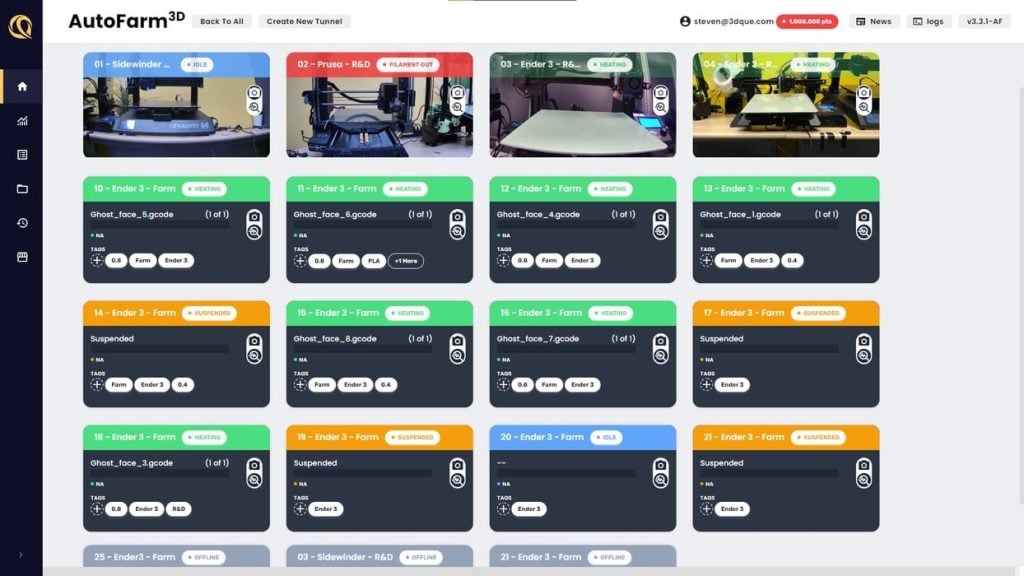

- Central dashboard

- Central file management

- Auto-eject when prints complete

- AI-powered failure detection

- Statistics and data reporting

- Secure remote access and control

- Printer identifiers

- Tracking and traceability of print jobs

In addition, the software is designed to be as plug and play as possible, and offers the ability to customize workflows and functions with a wide variety of configurations. In all, the system should save a considerable amount of manual effort when managing a medium-sized 3D print farm.

3DQue founder Mateo Pekic said:

“Manual farms running on old technology are less productive because tasks cannot be done in bulk, and every printer needs to be micromanaged. AutoFarm3D treats your 3D print farm as a single interconnected system, rather than a set of isolated machines. It is the first software designed specifically for FDM print farms of all sizes and compatible with a mixed range of 3D printers, materials, colors, and part designs.”

The system is able to auto-dispatch jobs to the right kind of 3D printer in a farm by keeping track of printer types and availability.

One of the often forgotten aspects of printer management is the paperwork, and here AutoFarm3D is able to collect the necessary data for the operator. This should allow proper calculations of costs, part pricing and also the ability to identify ways to optimize farm operations.

3DQue is apparently working with a number of existing 3D print farms to implement the software, including one that is said to have more than one thousand 3D printers involved.

If you’re operating or considering operating a 3D print farm of any size, you might want to check out 3DQue’s automation solutions.

Via 3DQue