3DQue announced the availability of their 3D printer automation system for several new 3D printer models.

The company’s VAAPR technology is a sophisticated thermal-chemical process that allows full control over the adhesive properties of a FFF 3D printer’s print surface. It is possible to electronically control when a print sticks and when it is to be released.

3DQue leveraged this capability into a system where a completed print could be automatically removed from the printer by gravity. The company’s initial product was arrays of inexpensive 3D printers mounted sideways, where prints can simply fall out into a collector when complete.

This simple change transforms a 3D printer into a kind of small factory. Typical 3D printers require manual intervention on each and every print job, severely limiting the ability to economically produce quantities of objects. But with a print removal automation system it is possible for the device to run more-or-less continuously, producing objects. The operator need only add a new spool of material occasionally, drastically reducing labor costs.

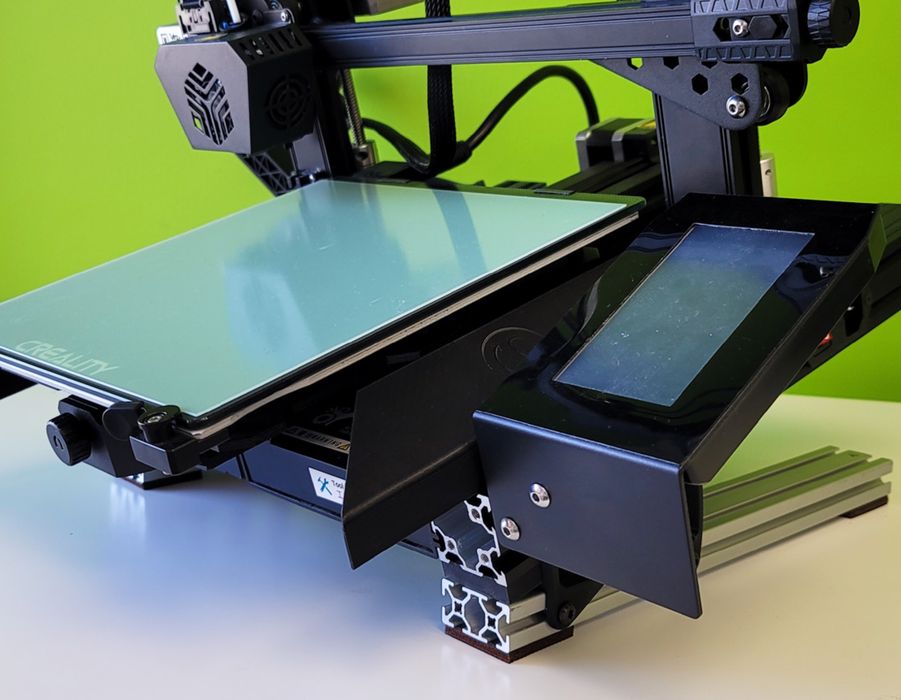

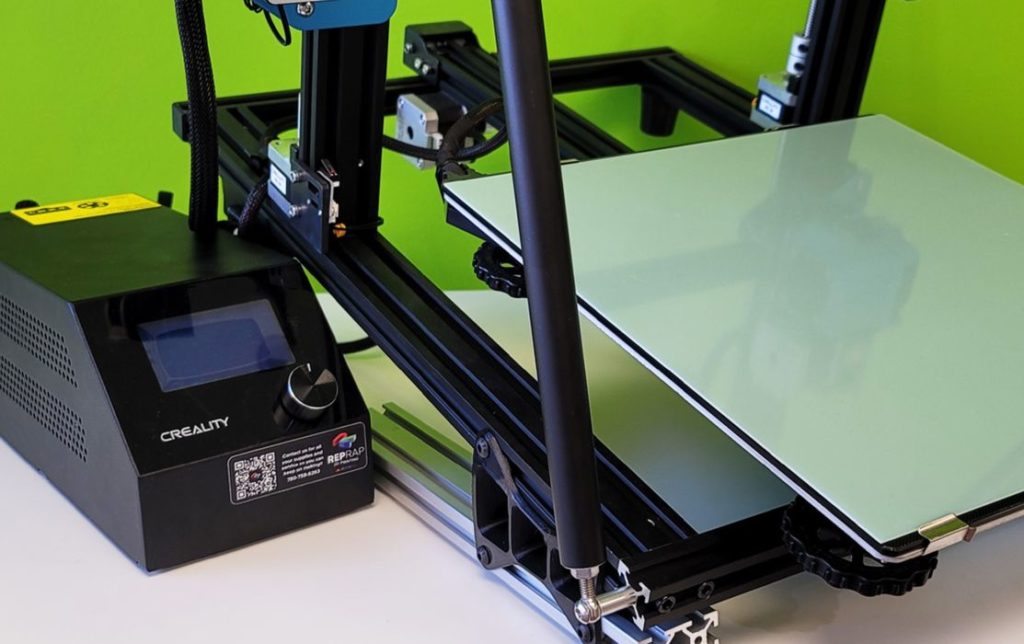

Their array system used the popular Creality Ender 3 as the base printer, modified with the addition of the VAAPR technology.

However, over time the company realized they could offer an upgrade kit for individual 3D printer operators of Ender 3 gear for their own automation experiments and even real production, albeit at low volumes.

Their “Quinly” upgrade product proved quite popular, and they subsequently added versions compatible with other 3D printers. Now they are adding even more 3D printers to the mix.

The new models compatible with Quinly are all Creality models: CR-10, CR-10S, CR-10V2, CR10V3, or CR-6SE. Each of these devices is quite popular, meaning an inexpensive automation is available for many tens of thousands more 3D printers.

Some of these devices will be operating in production farm environments, meaning the managers could potentially upgrade their 3D printers with Quinly and dramatically save on part production costs.

3DQue explains:

“Quinly software can activate CR6SE’s bed leveling and filament sensor, allowing it to run days on end without any user input. Operators are notified if filament runs out or if bed-levelling maintenance is required.

The high performance VAAPR print bed included with the CR-6 SE provides reliable adhesion on its own, eliminating the need for glue or other adhesives. When cooled after printing, the VAAPR print bed completely releases parts, clearing the bed for the next print to begin automatically.”

Today the company offers Quinly upgrades for these machines:

- Aquila

- CR-6SE

- CR-10

- Ender 3

- Ender 3 V2

- Ender 3 Pro

- Prusa MK3/S/+

- Prusa MK3 Clones

They are beta testing these machines, which at some point will be generally available for purchase:

- Ender 3 Max

- Prusa Bear

- Sidewinder

- Ultimaker S5

3DQue’s solution seems to be one of the most inexpensive ways to introduce automation on low cost 3D printers, and I’m surprised some 3D printer manufacturers don’t partner directly with 3DQue to integrate the Quinly technology right from the factory for clients.

But that is certainly something that may happen in the future.

In the meantime, I expect 3DQue will be developing upgrade kits for even more popular 3D printers.

The Quinly for the new devices are available for re-order now.

Via 3DQue