3DEO announced they’ve produced their 1,000,000th 3D printed metal part.

This is quite an achievement for the startup company we first encountered back in 2017.

3DEO is a Los Angeles-based additive manufacturing service that can produce relatively high volumes of small metal parts in outstanding quality.

They can do this through their “manufacturing cloud” which behind the scenes is an array of proprietary equipment that can 3D print metal objects quite efficiently.

We interviewed 3DEO’s Matt Sand a few years ago, where you can find out many details of their secret process. Briefly: it uses a binder jet process on fine metal powder, combined with a layer-by-layer CNC milling process. This produces high-quality green parts that can then be sintered to form 99% dense metal objects suitable for end-use.

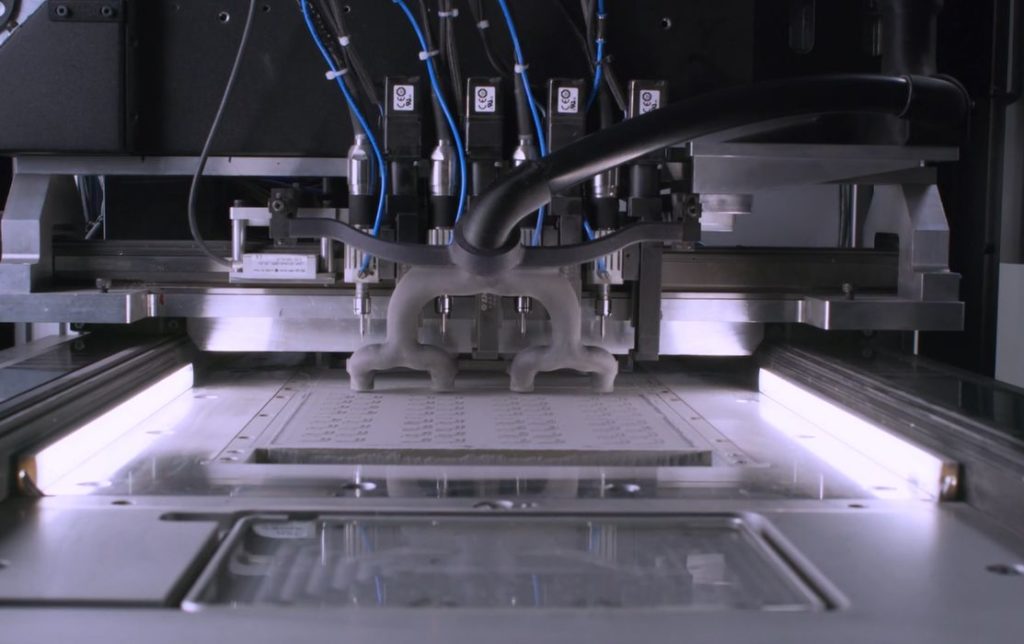

Above we can see an image of their system in action. Note that the toolhead contains multiple active elements. As the toolhead moves, it can print multiple objects in parallel. That’s one part of their efficiency scheme, but there are more.

The system is able to produce small metal objects quite rapidly, and by having multiple machines it’s possible to generate considerable throughput. 3DEO intends to operate a facility that can produce up to 100,000 finished metal objects per day. Not per week or per month, that’s per day!

I am not certain any other AM facility has that level of throughput. However, note that the parts being made by 3DEO tend to be small in size.

Today’s announcement of their 1,000,000th part is significant because they only launched their full service last year. If you do the math, they seem to be producing thousands of parts per day, so reaching 100,000 per day is clearly feasible with their technology.

Here’s their video describing the project that put them over the top:

The last time we spoke with 3DEO, their strategy was to operate as a manufacturing service, and they do not intend to sell their equipment directly to manufacturers. This allows them to continue to optimize their systems and process, while providing service to clients.

It’s a fascinating business model, because it is financially feasible for smaller manufacturers. Normally metal 3D printing is out of range for all but aerospace, automotive and oil & gas clients due to the cost of prints. But 3DEO’s small metal prints are actually quite affordable for manufacturers.

3DEO has grown significantly in the past two years, and it’s likely they will continue to do so. At some point in the future I could see them opening up additional facilities in other regions as part of a growth strategy.

Meanwhile, they’re working towards their two millionth part.

Via 3DEO and BusinessWire