3D Systems’ recent acquisition of Volumetric and its continued collaboration with other biotech companies pushes 3D bioprinting capabilities into the future.

An aging population with high chronic respiratory rates, a global pandemic and minimal organ donors have all paved the way for 3D bioprinting to become a potential replacement organ solution, and 3D Systems is taking the lead in its progress. The company, which has long been a leader of 3D printing in health care, recently acquired Volumetric Biotechnologies, a company dedicated to engineering vascularized tissue, and has been collaborating with United Therapeutics (UT) and other biotech companies to further advance 3D bioprinting capabilities.

“For years we have developed and produced advanced medical products for the human body using additive manufacturing in a highly disciplined, process-controlled and FDA-regulated environment,” said Jeffrey Graves, 3D Systems president and CEO. “With this foundation, if you look at the progress we have now made in all of the essential hardware, software and materials elements of bioprinting, we have the opportunity as a company to address a variety of applications within the human body. That’s why we’re increasing our funding and investment and expanding our partnerships to make these applications a reality.”

Efforts by 3D systems and United Therapeutics’ organ manufacturing and transplantation-focused subsidiary, Lung Biotechnology PBC, have come a long way since they began collaborating in 2017. With the goal of developing regenerative medicine applications, the companies have focused on a platform for lung modeling.

“Over the last years as bioprinting and regenerative medicine have evolved, we’ve seen a growing need to place cells at high-resolution in a nurturing matrix to produce complex tissues,” said Chuck Hull, 3D Systems cofounder, executive vice president and chief technology officer. “Precise 3D printing with hydrogels, followed by perfusion of cells into the printed scaffold is the best way to achieve this, and we are thankful our work with United Therapeutics has given us the opportunity to advance and perfect this technology.”

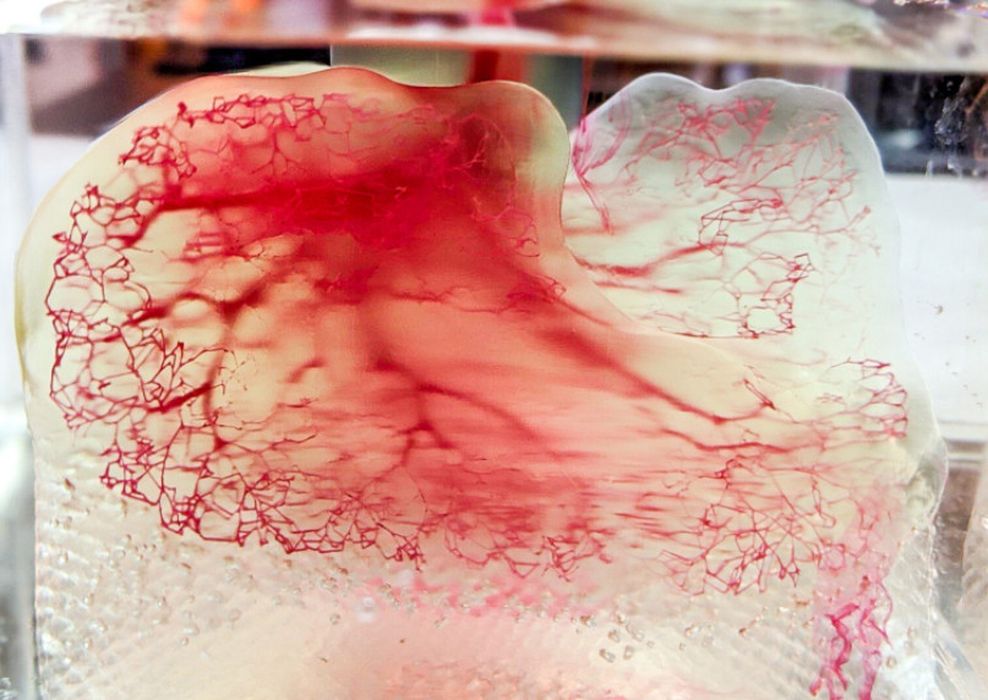

In 2020, the companies developed a process, Print to Perfusion, to rapidly fabricate high-resolution vascularized scaffolds. These 3D-printed scaffolds are perfused with living cells, enabling the creation of tissues and personalized human lungs. Featuring micron-level details, this process has opened the door to additional tissue applications for other organs, further advancing what 3D bioprinting may have to offer.

“Imagine a very fine, highly detailed sponge-like structure with wall thicknesses a fraction of the diameter of a human hair, but yet strong enough to support cell growth and blood flow needed to sustain life,” Graves said. “It allows for the creation of organs using actual human cells, which will reduce the chance the body rejects the transplant. The structure is designed and created to allow vascularization, so there’s plenty of blood flowing to the tissues. That’s what we’ve achieved with UT. The potential for positively impacting humanity is remarkable. Outside of solid organs, think about replacement tissue for trauma patients or tissue to allow for better breast reconstruction for cancer survivors.”

3D Systems has steadily been adding partners to cover every facet of bioprinting innovation. It has partnered with Collplant, a developer of proprietary recombinant human collagen BioInk technology, and Antleron, a pioneer of regenerative medicine. The addition of Volumetric Biotechnologies is set to take these technologies even further. Volumetric Biotechnologies was founded in 2018 by bioengineers Jordan Miller, Ph.D. and Bagrat Grigoryan, Ph.D. Their ground-breaking research set the company on a mission to manufacture human organs via bioprinting, primarily the liver.

Read more at ENGINEERING.com