3D Systems announced a new series of industrial 3D printers, the SLA 750.

The series currently includes the base SLA 750 and the SLA 750 Dual. The two machines provide an incredible improvement over conventional SLA 3D printers in both speed and throughput.

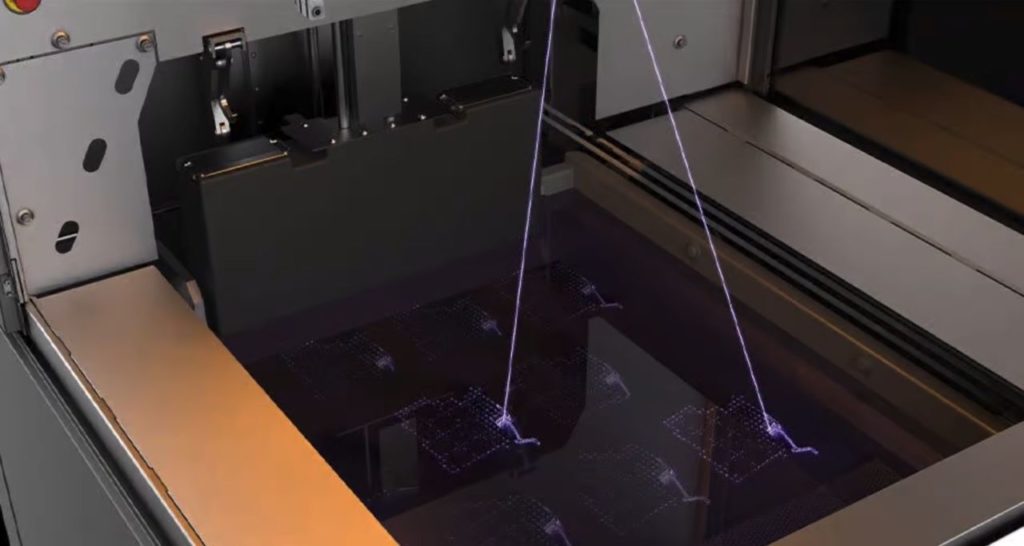

3D Systems bills the new devices as the “industry’s fastest SLA 3D printers”, and they are probably correct. The speed increase is partly due to the 750 Dual’s use of twin lasers.

Adding additional lasers has long been a tactic on metal 3D printers to increase speeds, but up to now it has not been attempted on SLA equipment. That changes with the new 750 Dual, which is equipped with two lasers that 3D Systems said “doubles print speed and triples throughput”. This is an interesting move and perhaps we may see even more lasers in future models.

But that’s not the only reason for the increased speed. 3D Systems has also introduced a new proprietary scanning system they call “Hyper-scan vector technology”, which seems to more precisely tune the key parameters of focus, power, speed and motion to achieve better and faster results.

The two machines are actually quite large, offering a build volume of 1050 x 750 x 600 mm (you can see where they derived the systems’ name). This makes the devices ideal to produce large, finely detailed parts for industry.

What’s even more interesting is that 3D Systems has chosen to not simply announce a new machine, but they’re also announcing a complete set of associated tools, software and materials.

The announcement includes a new series of materials 3D Systems has branded “Accura”. The first material in the series is AMX Durable Natural, which provides for production-grade parts that are resistant to the environment. The material has a high elongation and and can withstand a great deal of flexing. Parts made with this material can be used in a wide variety of scenarios, including jigs and fixtures.

The company also announced a post processing device to accompany the SLA 750 devices, the PostCure 1050 (again you can see where they get the name from). This smart device is specifically designed to handle prints from the SLA 750s, where it provides rapid drying and curing functions. 3D Systems said it can process fresh parts up to 5X faster than comparable solutions.

For software, the SLA 750s work directly with 3D Sprint, the company’s flagship 3D printer management software. But also the machines also directly connect with Oqton’s Manufacturing OS, software now owned by 3D Systems after their recent acquisition of Oqton.

These additional announcements make the SLA 750s much more compelling as a complete solution should be of greater interest to buyers, particularly those stepping into AM or moving to a larger solution.

Via 3D Systems