Charles R. Goulding and Preeti Sulibhavi discuss how companies in the medtech industry can leverage 3D printing to enhance customization and fit of hearing aids.

A little over a year ago we covered the FDA’s approval of over-the-counter (OTC) hearing aids. However, OTC hearing aid sales have been slower than expected.

A recent article in the New York Times (NYT) pointed out the other potential health benefits of hearing aids. In Paula Span’s article titled, “A Challenging Over-the-Counter Market for Hearing Aids,” she provided some background on a 2020 Lancet Commission on Dementia Prevention, Intervention and Care study that identified hearing loss as the greatest potentially modifiable risk factor for dementia.

You heard that correctly. Yes, specifically in older and less-affluent populations, the study found that hearing aids reduced the rate of cognitive decline by 48 percent, a difference that is “clinically meaningful.”

There are opposing views and many contributing health factors to be considered as well. All that aside, wearing hearing aids is definitely something many seniors must do to communicate, maintain balance, and potentially reduce the risk of dementia on top of that. We have previously covered the eyeglasses integrated with hearing aids or “specaids” trend.

3D Printing and Hearing Aids

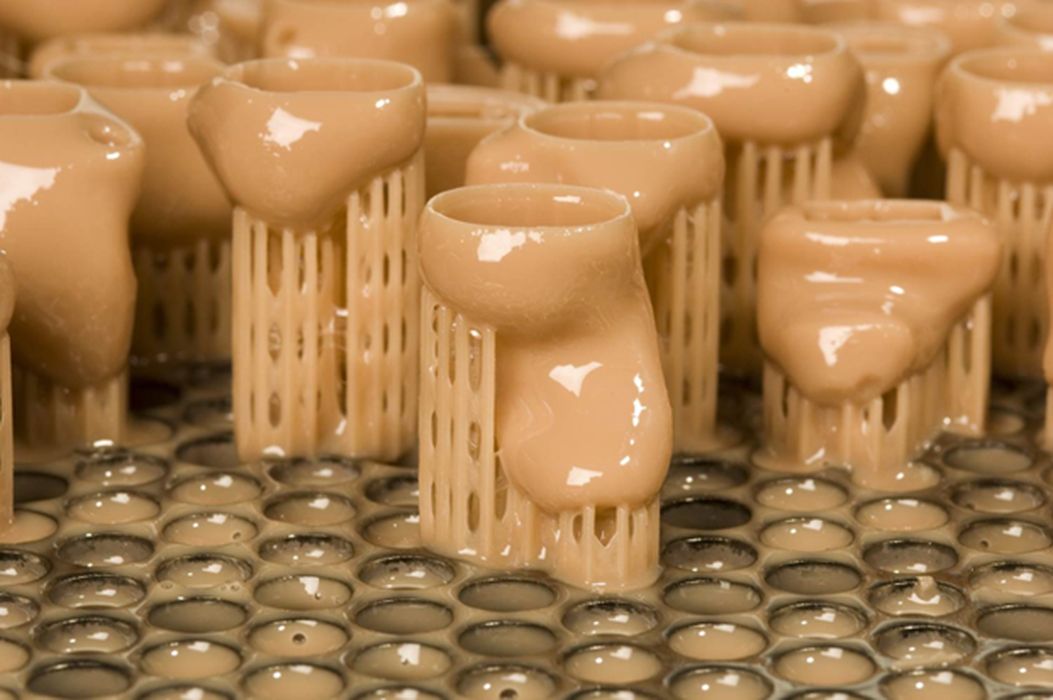

Ninety percent of hearing aids in the US are 3D printed. Using 3D printing technology in the medtech industry continues to show promising results. In terms of hearing aids, Danish hearing aid manufacturer, Widex has been using 3D printers for scanning, modeling, fabricating, mounting and polishing their hearing aids.

Especially with hearing aids, that need to be custom-fit to the patient’s individual ears, 3D printers are a useful and flexible solution. Just as we have covered how dental labs are using 3D printers to customize devices for their patient’s specific needs, audiologists can do much the same. Even for OTC hearing aids, pharmacies like CVS, can keep 3D printers on site and offer specialty services for seniors who need a little extra help with fitting their OTC hearing aids.

Phonak, a major hearing aid brand has partnered with EnvisionTEC (a leading 3D printing company) to create the smallest in-the-ear hearing aid to ever be printed. In fact, one of the well-recognized hearing aid brands, Sonova, also teamed up with Phonak to 3D print their hearing aids as well.

One obstacle to convincing seniors they need hearing aids is the bulky nature of the devices. 3D printed Phonak hearing aids are not only fashionable (less noticeable) but functional as well.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Not Just “Hear” Say

While there is still some objection to making a conclusive connection between dementia and hearing loss, current research is finding that hearing-aid use can slow cognitive decline. The who and how are still being hashed out, but one thing is clear, the 3D printing industry should not overlook this finding. The medtech industry is one of the fastest growing sectors for the 3D printing industry to advance its technology and innovation.