Charles R. Goulding and Preeti Sulibhavi look at how recent investment is stimulating increased use of 3D printing in one industry sector.

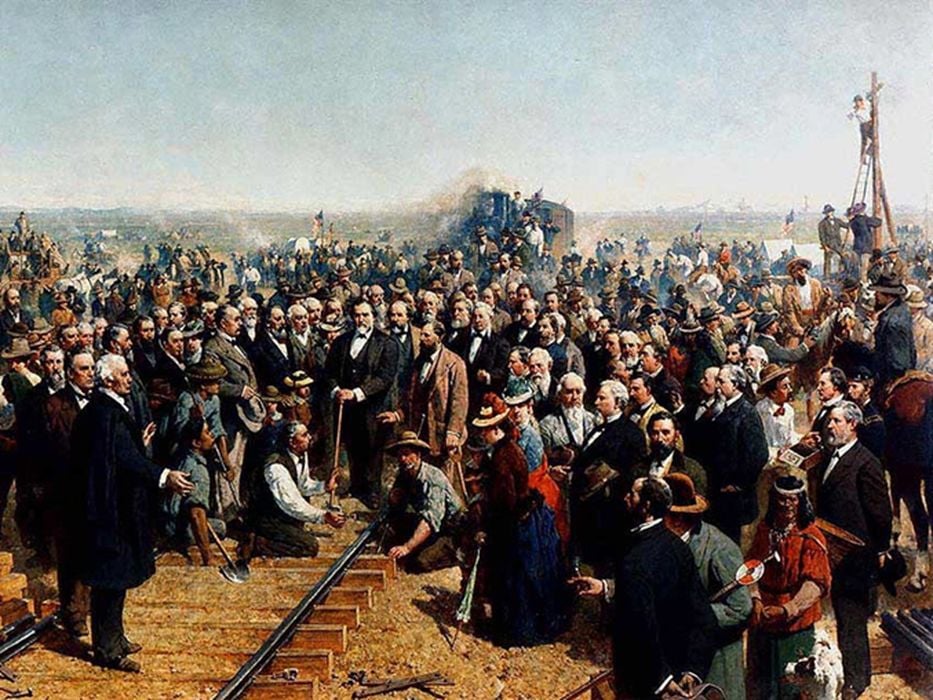

One of the famous examples illustrating the opportunities for supplying needed materials during an economic boom is Leland Stanford, who provided picks, shovels and supplies during the California gold rush.

Stanford, the namesake of Stanford University, went on to become a major force in the rail industry and fabulously wealthy. Neos Partners, a San Diego clean energy investment firm just raised US$800M which exceeded the US$500M goal to supply equipment for clean energy and infrastructure investment.

Investors included the Packard Foundation, University of Pennsylvania (UPENN), Yale, and coincidentally, Stanford University. The principals in Neo are very experienced investors formerly with Oaktree Capital Management, a leading investment firm with proven experience in this area including Shoals Technologies a provider of equipment used in solar, battery and electric vehicle systems.

The same week, Seurat Technologies received a large contract to supply over 50 tons of 3D printed components for Siemens Energy for wind turbine projects. Solar projects require large volumes of brackets and fasteners, which are suitable for 3D printing.

Water projects require pumps, valves, and seals, and filters, which are also suitable for 3D Printing. Many new technologies like direct carbon capture are coming of age where 3D printing and its generative design and digital twin capabilities can be incorporated into the project design as original equipment.

The alternative energy industry has a lot of moving parts and 3D printing can help develop high-quality components in the most cost-effective ways. Whether it is for the equipment used in generating alternative energy as described above or for fabricating replacement parts 3D printing is increasingly becoming the viable solution.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Sophisticated investors are now entering the alternative energy supply chain space, and their investments will ensure 3D printing has an important role to play in the alternative energy ecosystem.