TU Delft researchers have demonstrated 3D printing with waste cellulose and lignin materials.

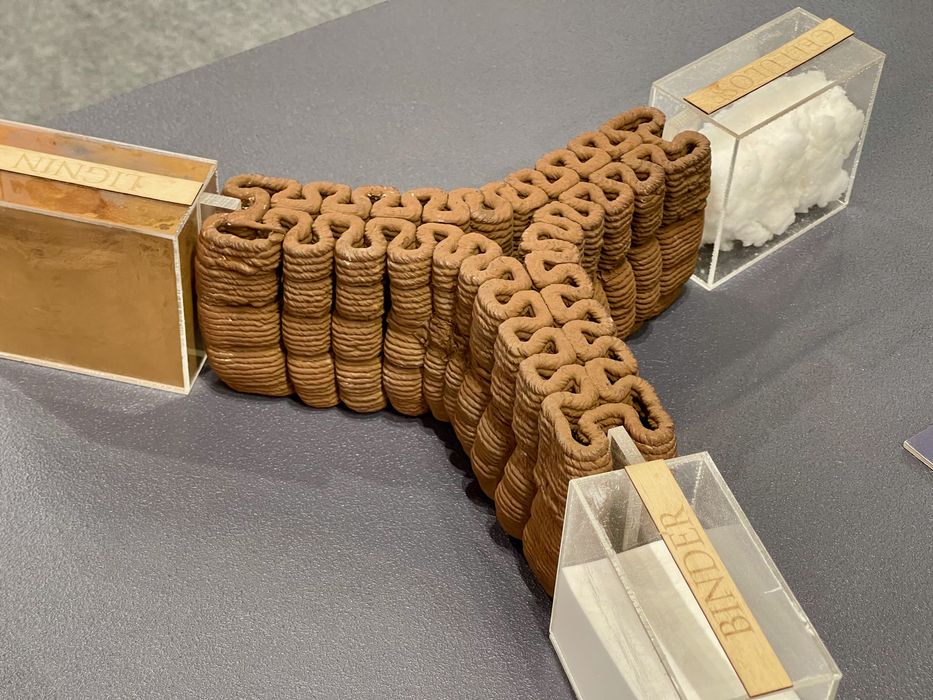

The large-sized print is actually a demonstration by researchers of the possibilities available when using cellulose and lignin as print materials.

It’s a large, coarsely layered 3D print with a peculiar newspaper-like coloration. It has no particular function, other than demonstrating that printing in this material is possible.

Cellulose and lignin are made by trees, and the two organic polymers make up the majority of mass of tree structures.

Lignin in particular is the stronger of the two, providing tree cells with stiffness necessary to grow to tall heights against the pull of gravity.

A little known fact is that when lignin first appeared millions of years ago, it was so tough a polymer that no bacteria were able to decompose it. For millennia trees grew and fell, without the lignin decomposing — and that’s where coal comes from. In fact, this era of around 300 million years ago is known as the “Carboniferous Period”. Eventually bacteria evolved to eat the lignin, and that period concluded.

Today lignin is still produced by trees, and is often a waste product from pulp and paper processing. The researchers believed it might be possible to make use of this otherwise waste material by converting it into a usable 3D print material.

They said:

“Coming from the pulp and paper industry, lignin waste could be implemented using an additive manufacturing process to reduce or avoid the necessity to cut trees. Thus, the aim of this research is to promote wood waste as an ecological contributor to the building industry.”

The material produced was a kind of paste that mixed cellulose, lignin and a binder. This material was eventually successfully extruded to produce the geometry shown at top.

But what was the mix of materials that proved successful? They explain:

“Cellulose and lignin were studied, analyzed and manipulated before mixing them with a vast selection of binding agents and additives. From a universe of 12 mixes and numerous iterations, for each recipe, for alternatives were picked for further characterization and determination of their mechanical properties. In parallel, the print ability of the material considered the most promising mix was explored through the extrusion of a sequence of simple geometries and shapes designed to understand and defined the most adequate printing parameters.”

It could be that this material may prove useful for a variety of 3D printing applications. However, the course nature of the output likely limits the applications to only those larger objects, such as architectural features or structural elements.

Via TU Delft