Charles Goulding and Warren Buzzell Jr. look at research and commercial efforts to combat brain injuries by using 3D printing appraoches.

A concussion is a form of mild traumatic brain injury (TBI) caused by a heavy blow to the head or a hit to the body that causes the head and brain to move back and forth rapidly. This forceful movement causes the brain to collide or twist within the skull, resulting in chemical changes in the brain and often damages and stretches brain cells.

They are often followed by temporary unconsciousness or confusion and are usually evaluated in contact sports like football, hockey, and rugby.

Over the past few years, movies such as Concussion–starring Will Smith–have drawn light into the severity of the injury and the importance of understanding solutions to mitigate risk for athletes and remedy the damage done.

The National Football League’s (NFL) Helmet Challenge has pitted rising innovators and some of the brightest minds in the 3D printing industry against each other to stimulate the development of a new helmet that outperforms all pre-existing helmet models. This is due to the alarming numbers of players who experience concussions and chronic traumatic encephalopathy (CTE) due to the physical nature of the sport.

Among the winners of the challenge are teams such as Kollide and Xenith, who leveraged 3D printing technology to develop unique solutions. Kollide’s helmet design incorporated 3D printing to develop both the structure and its 3D KORE technology that collapses to absorb force during impact.

Xenith, on the other hand, utilized 3D printed molds to develop a “unique energy control cell that cushions low-speed impacts, but intelligently strengthens for high-speed impacts,” where “cells compress to absorb linear impact and shear to optimally control rotational impact energy, reducing the resulting acceleration of the head.”

By leveraging 3D printing technology, both teams developed custom helmet designs with both lightweight and protective capabilities.

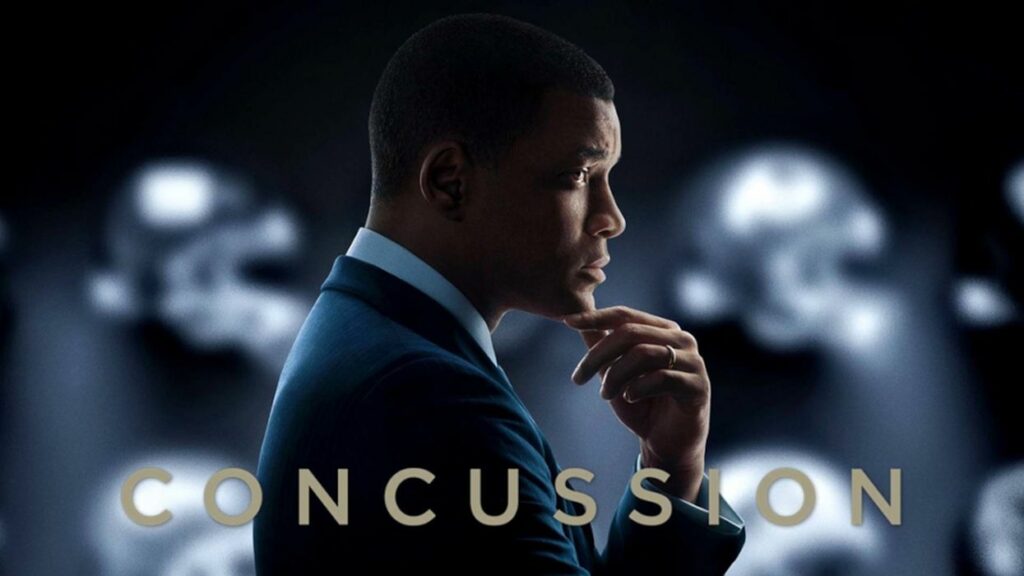

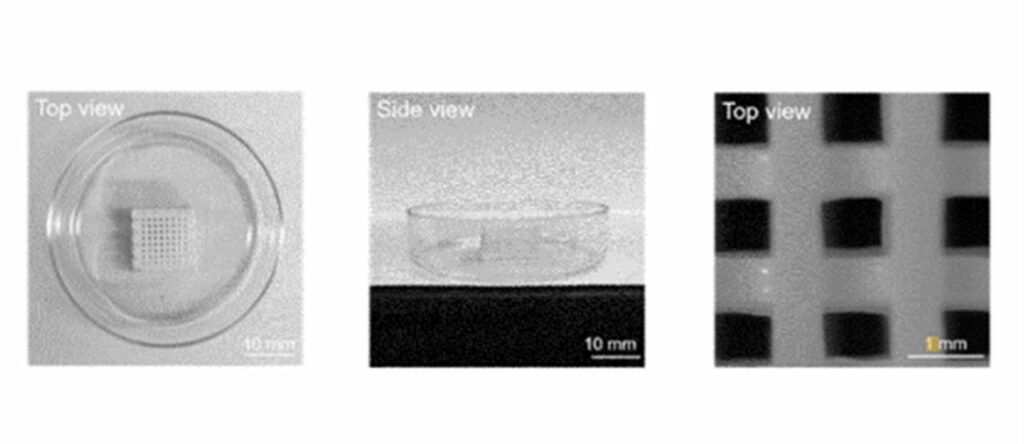

Warren Buzzell, a member of our firm, has had the opportunity to conduct research in the field of traumatic brain injury at Robert Morris University. He and his principal investigator, Dr. Rika Carlsen, utilized 3D printing (pictured below) to gain valuable insight into the phenomenon.

Currently, as per the Center for Disease Control, the only solutions we have to remedy the injury include rest and a gradual ramp-up of activity from light to moderate until regular activity levels are achievable without experiencing symptoms. So, rapid prototyping and custom design in research avenues are essential to developing more streamlined solutions.

A 3D printed mold was developed to fabricate hydrogels, which would be used to analyze and evaluate the strain experienced on the brain via impact testing.

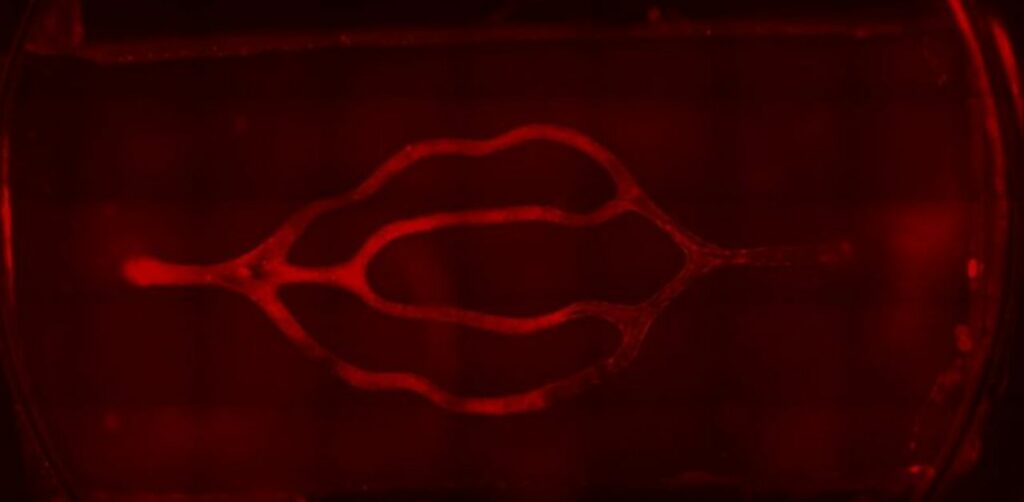

Extensive research and development efforts have accumulated evidence to confirm the efficacy of biomaterials and 3D printing technology as viable solutions for understanding TBI. For example, researchers at the Lewis Katz School of Medicine at Temple University in Philadelphia have utilized CELLINK’s light-based Lumen X+TM 3D bioprinter to develop a 3D bioprinted scaffold to observe the effect of TBI on tight junctions between endothelial cells and the blood-brain barrier.

3D printing enabled both flexibility and ingenuity in their research efforts, allowing the team to construct a 3D scaffold of the brain’s microvessels–ranging from 100 to 300 microns in diameter.

Furthermore, researchers from Qrons, a NY-based biotechnology start-up company, have developed 3D printable implants to treat TBI.

The findings were so innovative that the company filed for a patent to protect its novel invention. TBI is difficult to remedy because each injury can vary in shape, size, location, and spread. Unfortunately, penetrating injuries can result in mechanical damage and deformation of brain tissue, while non-penetrating issues result in widespread neuronal disruption.

The team developed its patented process, “Mechanically interlocked molecules-based materials for 3-D Printing,” to create injury-specific 3D printable implants for TBI. The process involves using 3D printed implants to transport genetically modified mesenchymal stem cells that secrete neuro-protective and neuro-regenerative agents to prevent additional neuronal damage and to stimulate neurons to migrate into the injury site, regrow axonal processes, and regenerate brain tissue.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. For example, wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Therefore, companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Traumatic brain injuries are prevalent, impacting the lives of more than 200,000 people in the United States per year. Although widely identified in athletes, the average person is also susceptible to injury if they receive a sudden force to their head. Thankfully, we have seen an increase in 3D printing to design both research solutions to help understand the injury and develop preventative hardware to reduce the risk of receiving it. Hopefully, we will continue to see growth in the utilization of 3D printing technology in TBI research.