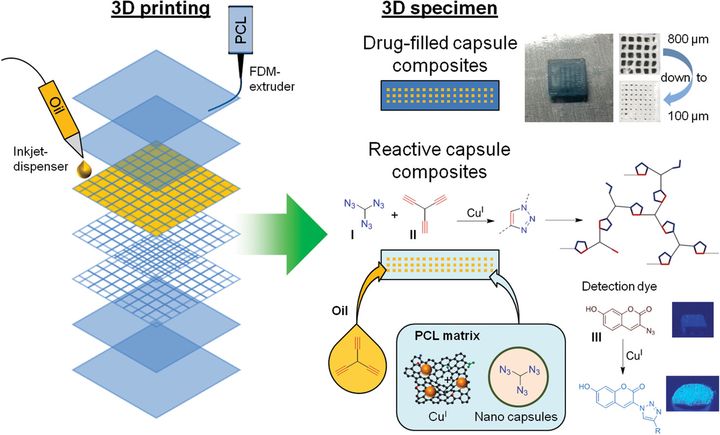

New research has developed a method of including microscopic capsules of liquid within 3D prints.

The idea here is pretty straightforward, but the details are quite challenging: embed small voids in a 3D print and fill them with a selected liquid material.

Why do this? There are plenty of potential applications, all of which depend on the liquid being released upon encountering some kind of trigger. For example, if the material were stressed to a particular degree, the voids holding the liquid might breach, allowing the liquid to escape. A liquid sensor could then detect the released liquid and thus you’ve made yourself a stress sensor.

There are other potential applications in healthcare, where drugs could be released in a variety of situations.

But how, exactly, do you get a liquid embedded in a 3D print?

That was the subject of this new research, and the biggest challenges turned out to be thermal in nature. Imagine simply 3D printing some ABS material with a cleverly placed void. When still uncovered, you might squirt a drop into the void and then cover it over with more layers of ABS.

In practice that might not work because the ABS material would still be quite hot, perhaps even over 200C at time of liquid deposition. For many useful liquids that might cause the liquid to evaporate before it’s even covered over!

Thus the researchers had to figure out how to 3D print materials at temperatures that would work for a wide variety of possible liquids.

They chose to start with PCL (polycaprolactone). PCL is a material that has been available in 3D printable filament form for quite a few years. In fact, we even wrote a story about PCL filament several years ago. That said, PCL is not a widely used material in 3D printing today in spite of its availability.

The problem with PCL is that its softening temperature is a mere 60C, making it entirely unsuitable for many mechanical applications. Imagine a PCL 3D print sitting on the dashboard of your car in the summer — it would be a puddle when you returned with the groceries!

However, in this case the low temperature is quite advantageous: the thermal difference between the hot PCL and the liquid drops is low enough to prevent evaporation. This means it was indeed possible to drop liquids into 3D print voids.

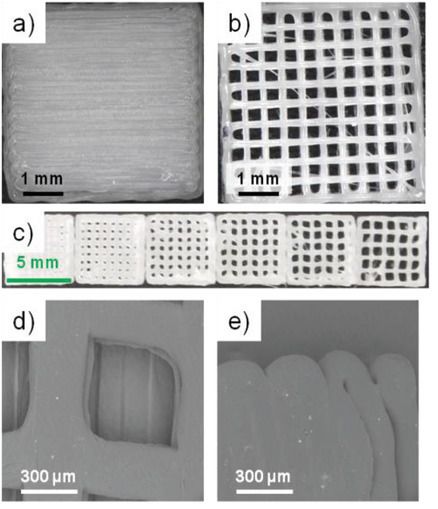

And that’s what the researchers did: they designed 3D models with small voids. Very small indeed: they designed experiments with voids ranging from 0.8mm to 0.1mm, and were successful in doing so.

Another challenge with this approach, particularly when using FFF 3D printing processes, is that the strands of extrusion do not always form a complete seal. It’s well-known that 3D prints can’t normally be expected to be watertight, and we explored the issue of waterproofing 3D prints in 2017.

The researchers here overcame that issue by a combination of 3D model and slicing parameters. They said:

“The base and top structures were designed in a CAD program creating fully closed layers with tightly connected polymer strands. The capsule structure between the base and top layers was programmed as an oil‐filled grid system that contained both grid directions (90° rotated) in one layer level. In the FDM process, the base layer was first manufactured and the polymer grid was deposited on top. The still open microcapsule voids were filled with the liquid oil by a second printing head and finally closed by the top layer, processed with FDM again.”

Another very intriguing possibility with this approach is the design of self-healing objects. If an object were damaged or penetrated, then the liquid would be released. If the liquid were designed as a healing agent, then the material could be restored to some degree.

It’s all quite interesting and I’m looking forward to further developments.

Via Wiley