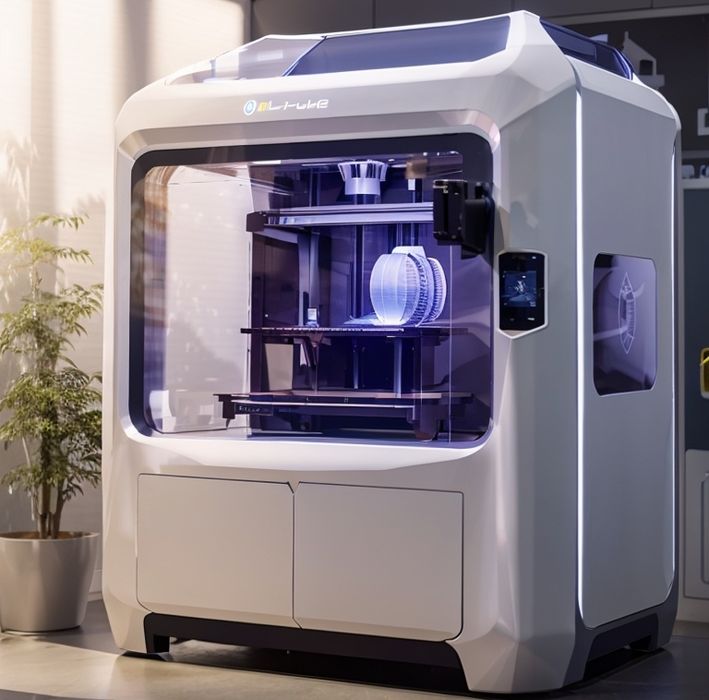

Last week I forecasted what a typical desktop FFF 3D printer of 2026 might look like. This week let’s go further ahead.

The typical desktop FFF 3D printer specifications for 2026 I proposed were a kind of extension to today’s machines. My thought was that features we’d see in today’s advanced expensive equipment would dribble down into lower price points within a couple of years.

The basic specs of the proposed 2026 machine were:

- Dual IDEX extruders

- Enclosed, assembled, heated

- High speed operation

- Large build volume

- Semi-high temperature capability

- LiDAR calibrations

- AI quality control

- Powerful control interface with cloud options

I received some comments about the story, with some suggesting that I didn’t go far enough, and that the proposed design was “linear”.

Really, this was true. It is simply an expectation that stuff we have today in expensive machines will be available at lower cost in the future. This has been the pattern for over a decade, and it’s likely to continue, at least for three years.

Much of the comments received suggested that AI technology could take a far bigger role in a future 3D printer, and that is almost certainly going to happen.

But what would that look like? What could be a fully AI-powered 3D printer of the future, say in 2030, look like?

Here’s some ideas.

AI Job Preparation

Today we all use separate software tools to prepare jobs for desktop 3D printers, a process known as “slicing”. Slicing might seem easy at first, but in fact it is enormously complicated if done correctly. Operators must tweak settings, set up different zones for processing, orient the model to take advantage of layer strengths, etc. This all requires considerable experience and time to set up.

What if that was all learned by an AI that could “do it” instantly for you?

The vision here would be a desktop 3D printer that does not come with or use any separate slicing software. Instead, the machine itself does the slicing when presented with a 3D model. The operator would merely have to specify things like:

- “Make sure the top doesn’t break off when used outdoors”

- “That hole might need reinforcement because it’s going to hold a metal bar”

- “Make four copies”

You get the idea. Instead of “text-to-image”, here we would have “text-to-print”. In fact, one idea would be to save collections of these statements in a kind of “meta profile” for certain types of parts.

The machine’s AI could be trained by the manufacturer and simply be ready to go immediately when sent a 3D model.

AI Model Modification

Let’s take that a bit farther. What if the 3D printer was also able to modify the 3D model itself? You can imagine modifiers like these in the meta-profile:

- “Make the ears really big”

- “That hole should fit an M5 bolt with thread”

- “Add two feathered wings on the back of the toaster”

This is a “text-to-3D” feature that we’re already seeing developed, but if so, why not integrate it directly into the 3D printer?

One of the reasons the general public doesn’t use 3D printers is that there is a pile of “complicated” software to run to make it work. A machine of this intelligence with the two features above could potentially destroy that barrier and enable sales of millions of 3D printers.

AI Material Configuration

In the old days you were lucky to get filament that worked at all. If you got a print, you were happy. But then machines improved, and the game became how to tweak things to get the best possible output.

This resulted in new processes to “calibrate” a new filament. Test prints would be repeatedly executed to determine the best flow rate, temperature, etc., for a given filament and 3D printer combination. Everyone’s printing #3DBenchys and temperature towers these days.

That’s tedious, time consuming, and yes, another consumer barrier.

What if this was done automatically? What if you could throw in ANY spool of filament, proprietary or not, into a 3D printer and its AI would then quickly test it to determine the correct settings?

I think this is technically possible to do with AI, LiDAR and a few other bits.

Operators would worry far less about filament quality and be more concerned with its color.

AI Model Search / Generation

Content is key for any 3D printer, as it doesn’t work without something to print. This has always been an issue, and solutions have included vast online repositories of 3D models and simplified CAD tools.

None of that really worked well enough to break through the consumer barrier. CAD tools are simply beyond the capability of most people, and it’s essentially impossible to find the desired 3D model in online repositories unless you are very persistent or willing to accept something different.

What if AI took over this work? What if an AI was able to instantly troll through the millions of online 3D models to select the very few that truly matched the requirements?

There’s more. What if that tool was able to not only pick relevant 3D models for you, but was then able to tweak them to perfectly match your requirements. If that was the case, then you basically have a tool that gets you exactly what you want.

Of course, there are limits to this. For professional part designs one would have to specify quite a few requirements. However, it may also be possible for AI tools to be trained to anticipate and automatically include many features.

AI Quality Control

If equipped with suitable sensors, such as an optical camera and/or a LiDAR scanner, it would be possible for an advanced 3D printer to continually scan the print in progress to ensure that it is in line with the intended geometry.

This would not only be a detection of a deviation, but it could also be a way to tweak the 3D printer’s operation on the fly to compensate for the deviation. Those tweaks would come from an AI-powered system trained on the types of deviations commonly seen. This would certainly result in extremely high quality prints and generally raise print reliability.

The Future of 3D Printing

These tools do not exist today, but one can begin to see that it just might be possible to attempt building them.

I suspect it would be unlikely for any specific 3D printer manufacturer to do so for two reasons:

- They’re not AI experts

- They’re busy building 3D printers

That’s why I expect some or all of the above concepts to first appear as accessories, add-ons or third party services. Then, over time, we might see 3D printer manufacturers begin to invent (or acquire) their own similar tools and integrate them directly into their equipment.

The future of 3D printing is going to be incredibly interesting, and if these capabilities do indeed come to pass, we just might see a 3D printer in every home, just as was forecasted a long time ago.