Charles R. Goulding and Preeti Sulibhavi believe recent corporate moves could boost 3D printing usage.

L3Harris Technologies, Inc, a leading defense firm, has agreed to buy Aerojet Rocketdyne Holdings, Inc, for US$4.7B. This would propel L3Harris to one of the six major defense contractors for the US Department of Defense (DoD). L3Harris’ all-cash bid beat out offers from General Electric Co and Textron Inc.

Aerojet was initially set to be acquired by Lockheed Martin Corp for US$4.4B but that deal was blocked by federal regulators on antitrust grounds.

The good news for the 3D printing industry is that this merger can provide additional resources for further innovation in 3D printing. Rocketdyne is already an industry leader in 3D printing, and material and design solutions.

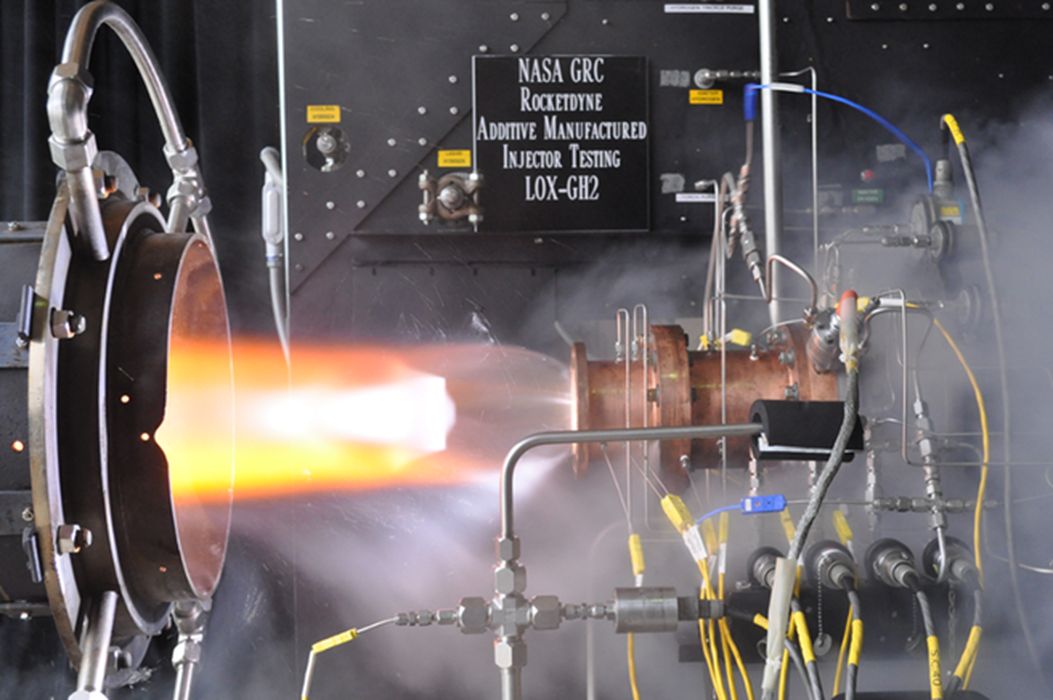

Aerojet Rocketdyne has invested extensive time and resources for more than two decades to evolve additive manufacturing technology, also known as 3D printing, to meet the stringent requirements of rocket engine and defense systems applications.

Aerojet Rocketdyne’s engineering team has refined its approach to the design process to incorporate new capabilities enabled by additive manufacturing. Engineers are free to design products that were once thought impossible due to the constraints of traditional manufacturing.

This investment is now paying dividends as Rocketdyne begins to incorporate the technology into production programs. 3D printing can significantly reduce lead times, make products more affordable, and enable new approaches to design that were not previously feasible. 3D printing has made a large impact on Aerojet Rocketdyne’s ability to deliver hypersonic flight.

L3Harris is no stranger to 3D printing either. In terms of 3D printing for electronics in space, radiofrequency (RF) communications systems are vital to low earth orbit objects (i.e., the International Space Station – ISS). L3Harris, using Nano Dimension’s DragonFly LDM system, was able to produce lightweight, high-performance electronic devices for use within RF systems allowing for rapid development time and the ability to create complex shapes and systems unachievable with traditional manufacturing techniques.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

We believe this merger will bring additional resources to Rocketdyne’s already innovative 3D printing activities. This will help both L3Harris and Rocketdyne design and develop larger-scale parts to be converted from conventional manufacturing to 3D printing, using multiple large selective laser melting machines to develop liquid rocket engine applications for national security space launch services.